Boiling type magnetic separator

The technology of a boiling magnetic separator and a magnetic separation device, which is applied in the field of magnetic separators, can solve problems such as the inability to effectively screen ultrafine powdered magnetic separation materials, and achieve easy installation and quick use, obvious iron removal effect, and smooth production process. The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

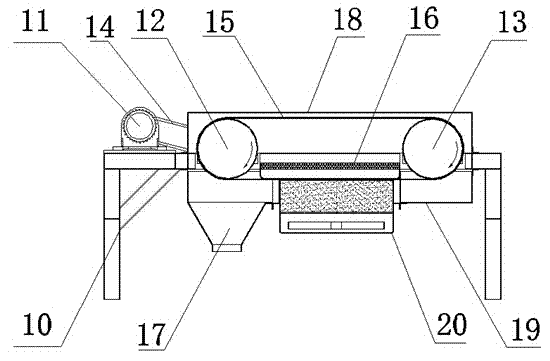

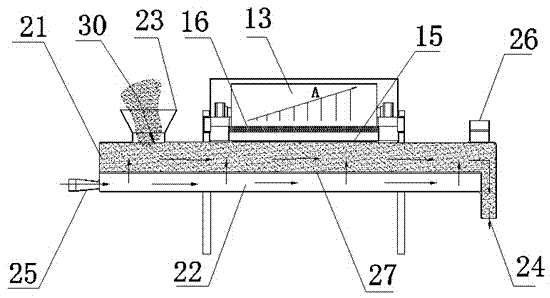

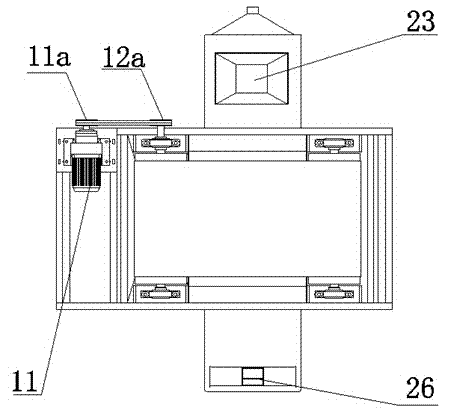

[0014] Refer to attached Figure 1-2 A kind of boiling type magnetic separator shown, it comprises magnetic separation device and material boiling device, and described magnetic separation device comprises frame 10, and the main beam in frame 10 is successively installed with driving drum 12, Magnetic system 16 and driven roller 13, motor 11 is also installed on the support 10 top, refer to image 3 As shown, a driving pulley 11a is installed on one side of the motor 11, and a driven pulley 12a is installed on the same side of the driving roller 12. The driving pulley 11a and the driven pulley 12a are connected through a first transmission belt 14, and the driving pulley 12 is connected with the driving pulley 12a. 12 and the driven roller 13 are connected through the second transmission belt 15, and the magnetic system 16 is located in the second transmission belt 15 and is close to the lower belt position for attracting magnetic materials. like figure 1 The transmission di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com