Preparation method of high-molecular fluorescent microsphere

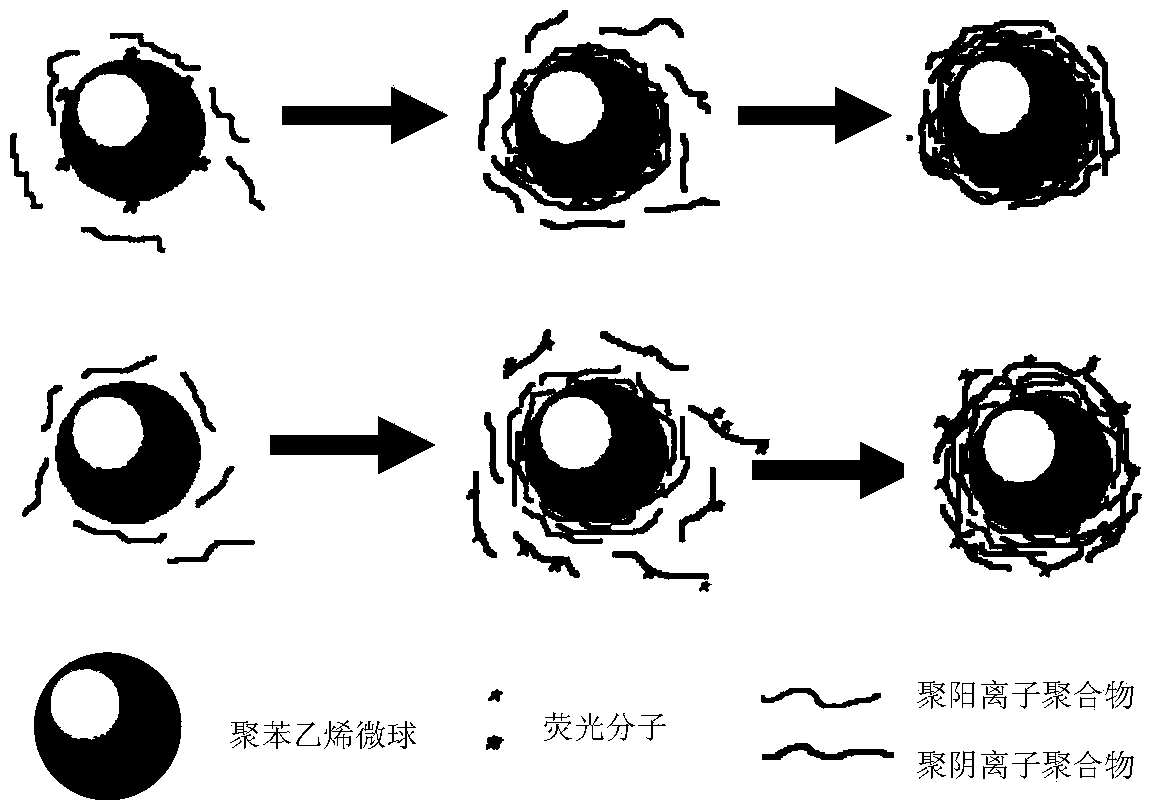

A fluorescent microsphere and polymer technology, applied in the field of preparation of polymer fluorescent microspheres, can solve problems such as coating materials that are easily affected by the surrounding environment and lack biocompatibility, and achieve good surface reactivity, good Optical properties, easy functionalization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Preparation of Surface Carboxylated Polystyrene Microspheres

[0052] Surface carboxylated polystyrene microspheres were prepared by two-step dispersion polymerization. First, 0.12g of initiator azobisisovaleronitrile (AMBN), 0.135g of stabilizer polyvinylpyrrolidone PVP360 (Mw=360000g / mol), 0.15g of co-stabilizer TX3050, and 3.0g of styrene monomer were dissolved in anhydrous Add 16.15mL of ethanol and 0.85mL of ultrapure water into a reaction kettle equipped with a stirrer, thermometer and reflux condensing device, stir and mix evenly, pass nitrogen to the reaction system for deoxidation treatment, and then place the above reaction kettle in an oil bath , heated to 60°C for 1 h; dissolve 3 g of styrene and 0.06 g of acrylic acid in a mixed solution of 7.6 mL of absolute ethanol and 0.4 mL of ultrapure water, add it to another reaction kettle, and pass nitrogen to the reaction system Deoxidize and heat to 60°C; react for 60min, add hot styrene and acrylic acid solu...

Embodiment 2

[0058] 1. Preparation of Surface Carboxylated Polystyrene Microspheres

[0059] Surface carboxylated polystyrene microspheres were prepared by two-step dispersion polymerization. First, 0.175g of initiator azobisisovaleronitrile (AMBN), 0.7g of stabilizer polyvinylpyrrolidone PVP55 (Mw=55000g / mol), 0.245g of co-stabilizer TX305, and 3.125g of styrene monomer were dissolved in anhydrous Add 13 mL of ethanol to a reaction kettle equipped with a stirrer, a thermometer and a reflux condensing device, stir and mix evenly, pass nitrogen gas through the reaction system for deoxidation treatment, then place the above reaction kettle in an oil bath, and heat to 60°C for 1 hour; Dissolve 3.125g of styrene and 0.125g of acrylic acid in 13mL of absolute ethanol, add to another reaction kettle, pass nitrogen gas to the reaction system for deoxidation treatment, and heat to 60°C; react for 90min, put the hot styrene and alkene The propionic acid solution was added into the reaction kettle,...

example 3

[0065] 1. Preparation of Surface Carboxylated Polystyrene Microspheres

[0066] Surface carboxylated polystyrene microspheres were prepared by two-step dispersion polymerization. First, 0.125g of initiator azobisisovaleronitrile (AMBN), 0.5g of stabilizer polyvinylpyrrolidone PVP55 (Mw=55000g / mol), 0.175g of co-stabilizer TX305, and 3.125g of styrene monomer were dissolved in anhydrous Add 25 mL of ethanol to a reaction kettle equipped with a stirrer, a thermometer and a reflux condensing device, stir and mix evenly, pass nitrogen gas through the reaction system for deoxidation treatment, then place the above reaction kettle in an oil bath, and heat to 60°C for 1 hour; Dissolve 3.125g of styrene and 0.125g of acrylic acid in 25mL of absolute ethanol, add to another reaction kettle, pass nitrogen gas to the reaction system for deoxidation treatment, and heat to 60°C; react for 60min, put the hot styrene and alkene The propionic acid solution was added into the reaction kettle,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com