A fully automatic dry powder fire extinguishing device

A dry powder fire extinguishing and fully automatic technology, which is applied in fire rescue and other fields, can solve the problems of mediocre effect, delayed fire extinguishing time, and no escape, and achieves the effects of flexible use, simple manufacture, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

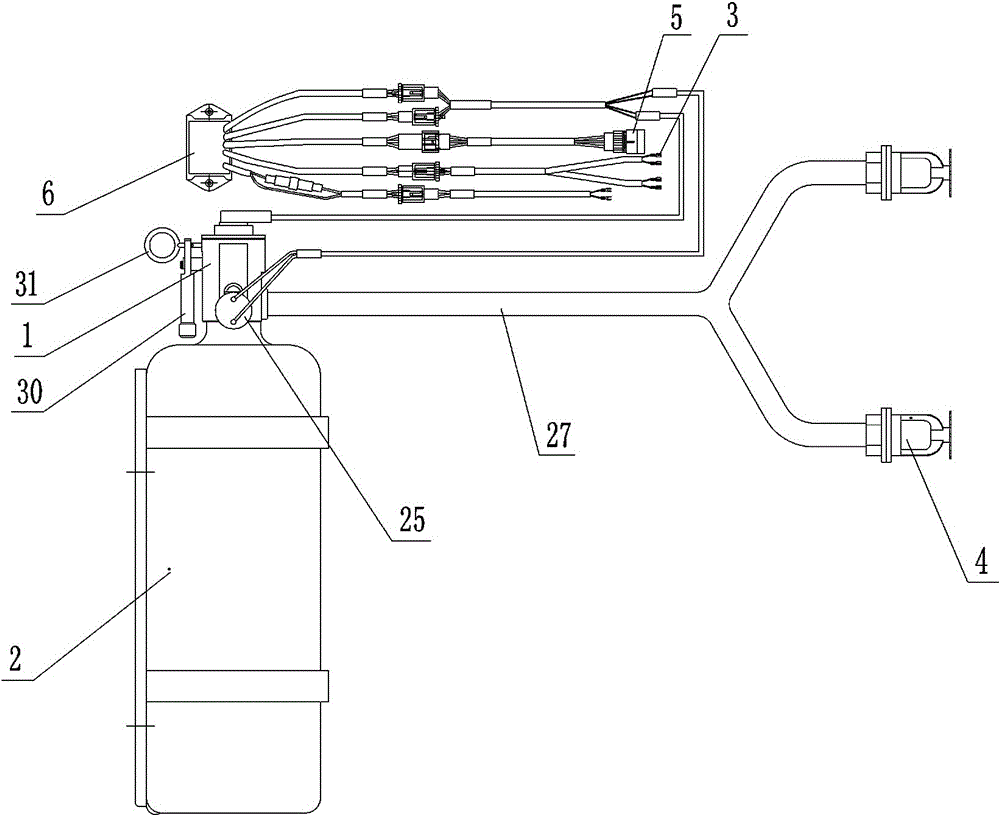

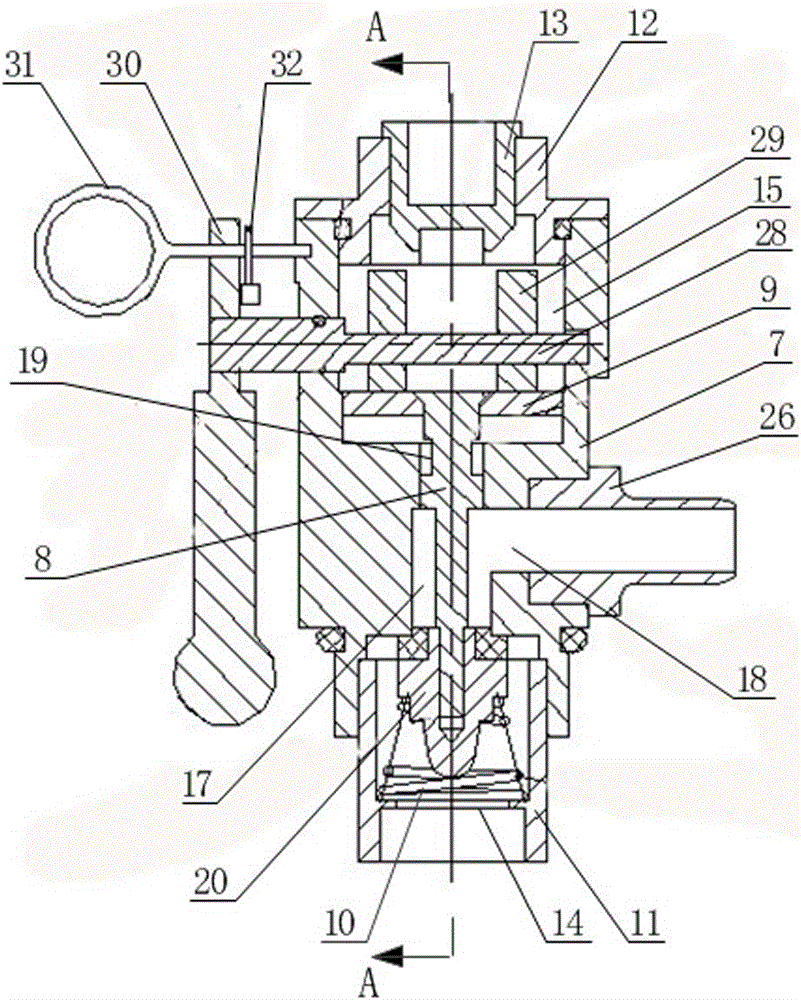

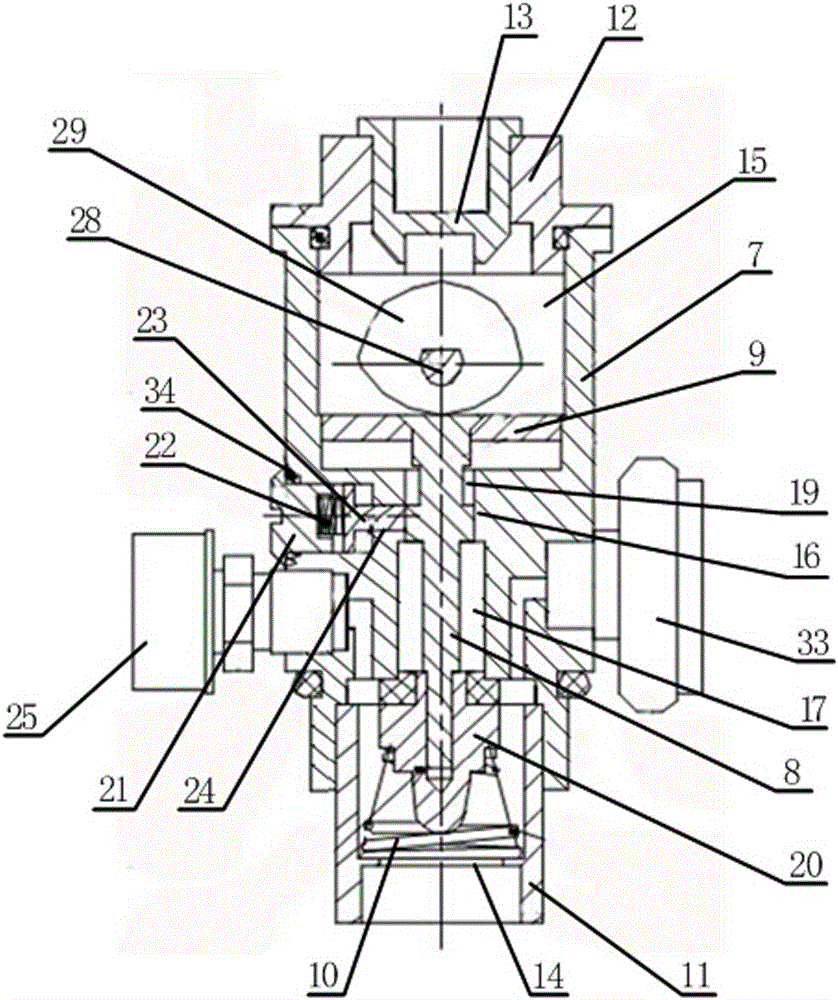

[0018] Such as Figure 1-3 As shown, a fully automatic dry powder fire extinguishing device includes a starting valve 1, a fire extinguisher tank 2, a temperature sensor 3, a nozzle 4, a button switch 5 and a controller 6, and the fire extinguisher tank 2 is filled with dry powder and high-pressure driving gas. The starting valve 1 is composed of a valve body 7, a piston rod 8, a piston rod limiter, a piston 9, a return spring 10, a bottom screw 11 and an upper cover 12, and the upper cover 12 and the bottom screw 11 are threadedly connected to the top of the valve body 7, Bottom screw 11 is cylindrical and the cylindrical surface of bottom screw 11 is provided with external thread, and the bottom of valve body 7 is provided with internal thread, and the external thread of bottom screw 11 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com