Cooling unit for traction converter

A traction converter, cooling unit technology, applied in cooling/ventilation/heating transformation, AC power input conversion to AC power output, electrical components, etc., can solve the problem of reducing the reliability of cooling units, falling off the protective bottom plate, and high air resistance problems, to achieve the effect of improving maintenance work efficiency, facilitating use and maintenance, optimizing matching and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

[0035] In order to realize the safe operation of EMUs with a speed of 350 kilometers per hour, according to the overall technical conditions of EMUs with a speed of 350 kilometers per hour, the technical conditions of water-cooled converters and cooling units of 6500V IGBT, and the appearance of cooling units for traction converters of existing EMUs The common faults of the traction converter have been innovatively designed.

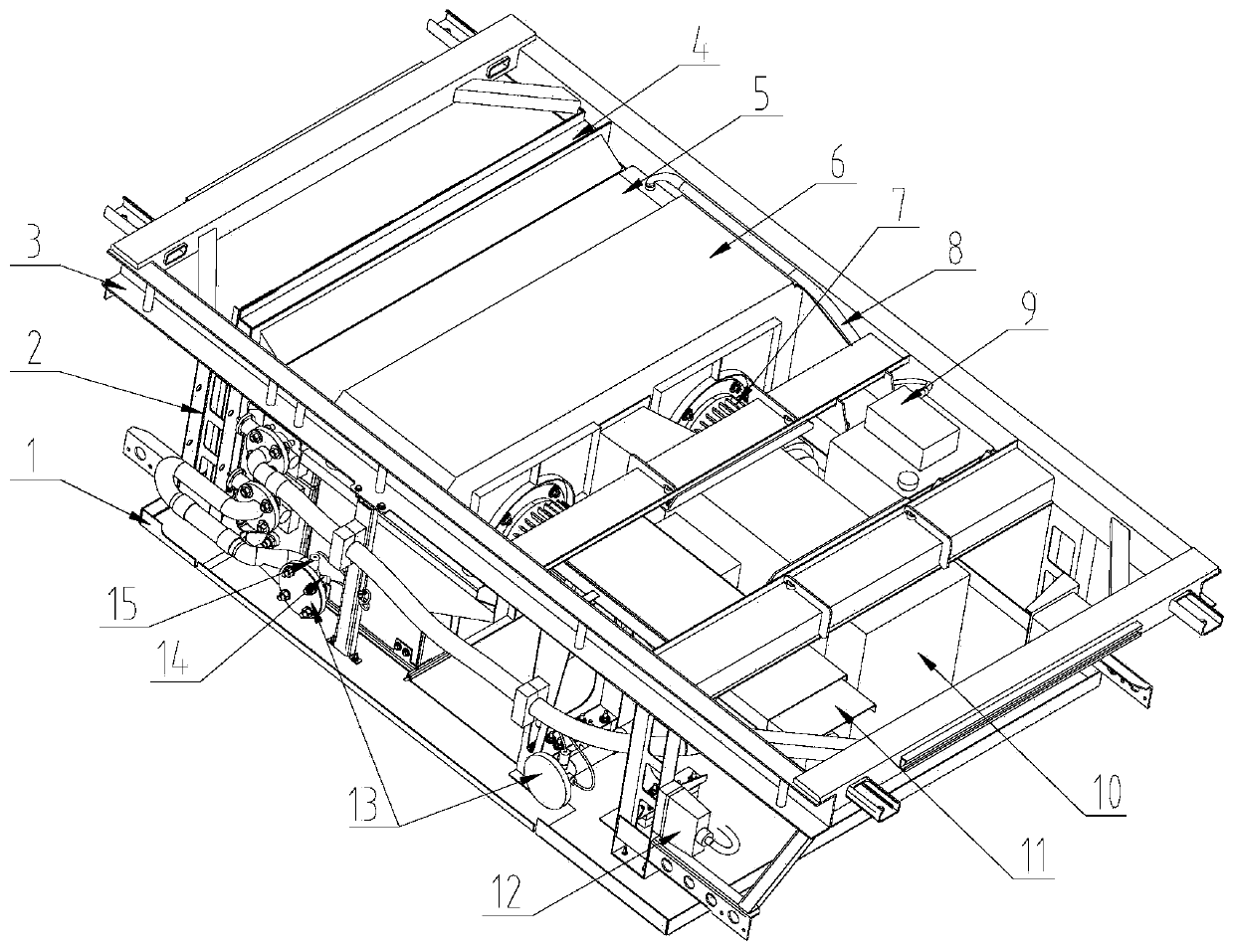

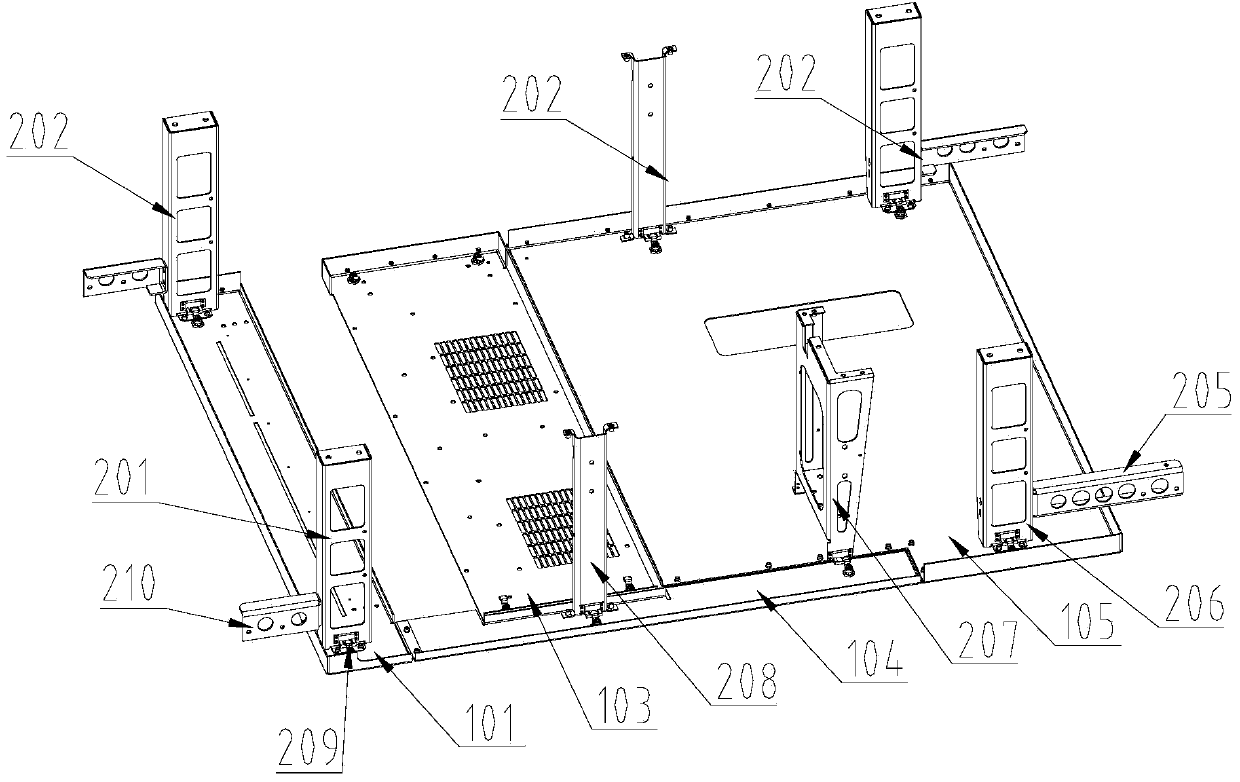

[0036] A traction converter cooling unit (such as figure 1As shown), including assembly of protective bottom plate 1, assembly of vertical load-bearing column 2, assembly of top load-bearing installation frame 3, assembly of filter 4, assembly of radiator 5, assembly of fan duct 6, assembly of fan unit 7, assembly of expansion tank 9, series connection Resonant inductor assembly 10, water pump assembly 11, water system auxiliary circulation pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com