A kind of preparation method of modified magnetic powder core

A magnetic powder core and modified technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., to achieve the effect of reducing noise, easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

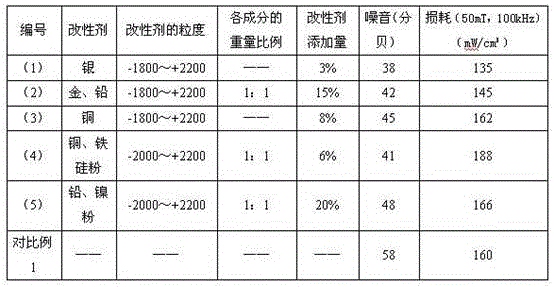

Examples

preparation example Construction

[0025] The preparation method of the modified magnetic powder core of the example provided in this embodiment includes the following steps,

[0026] Step 1, embrittlement treatment: heat-treat the FeSiB amorphous metal strip to make it embrittled and easily crushed;

[0027] Step 2, crushing: crushing the brittle amorphous metal strip to obtain amorphous metal powder;

[0028] Step 3, sieving and proportioning: sieving the amorphous metal powder, and then mixing it into powder particles of a certain composition;

[0029] Step 4, passivation treatment and insulation coating: Pour the proportioned amorphous powder particles into the mixer, stir and mix evenly, add passivation passivation agent, mix evenly, stir at a constant speed until dry; then add starting Mix the low-melting-point glass powder and epoxy resin for insulation bonding, and stir at a constant speed until dry.

[0030] Step 5, adding a modifier: adding a modifier to the insulating coated amorphous powder partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com