Heating type humidity sensor for sonde and preparation method thereof as well as humidity detection circuit

A humidity sensor and heating technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of large humidity fluctuations, influence of circuit board distributed capacitance measurement results, and easy condensation of humidity sensors, etc., to solve condensation, The effect of suppressing zero drift and suppressing temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

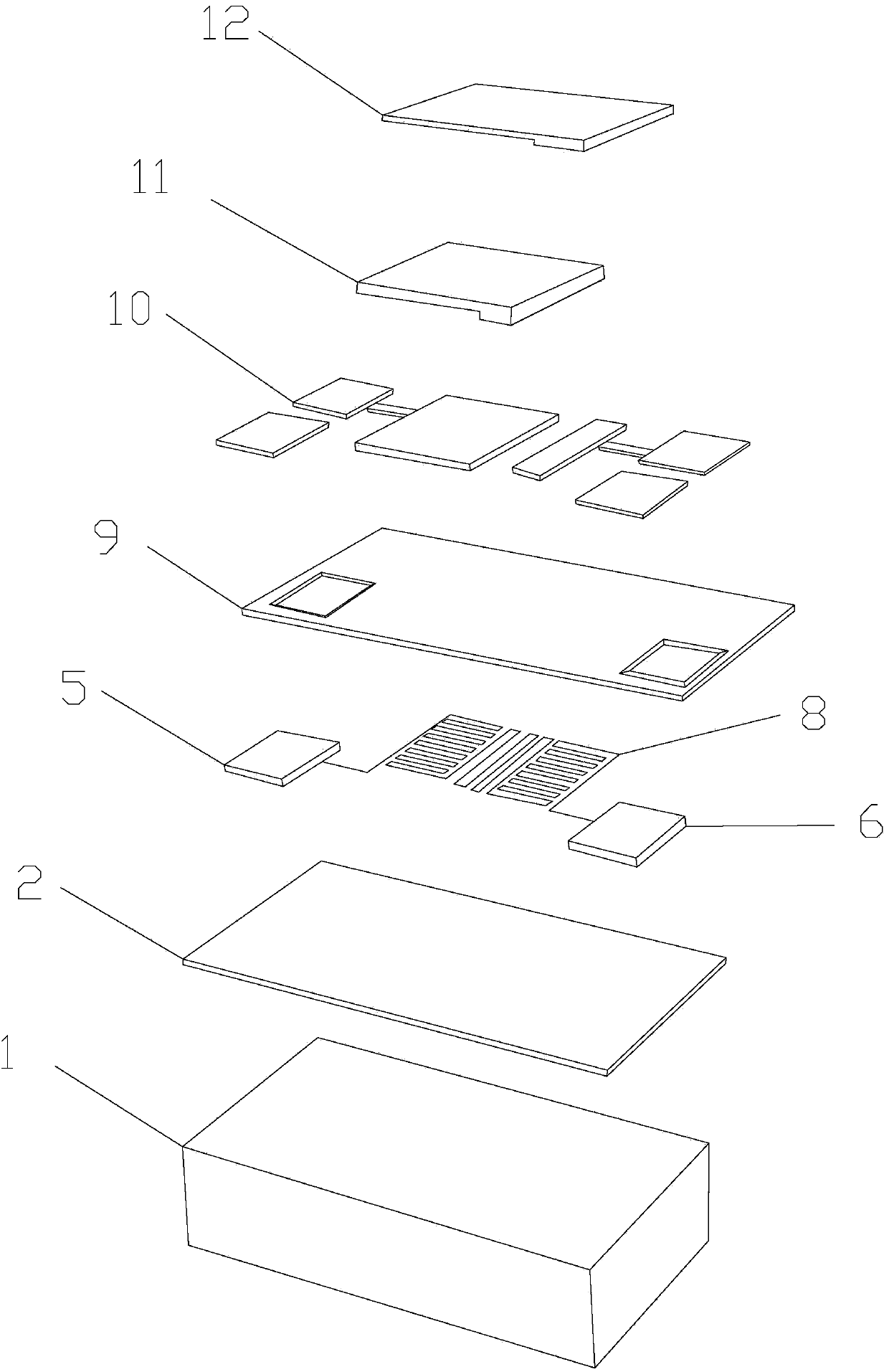

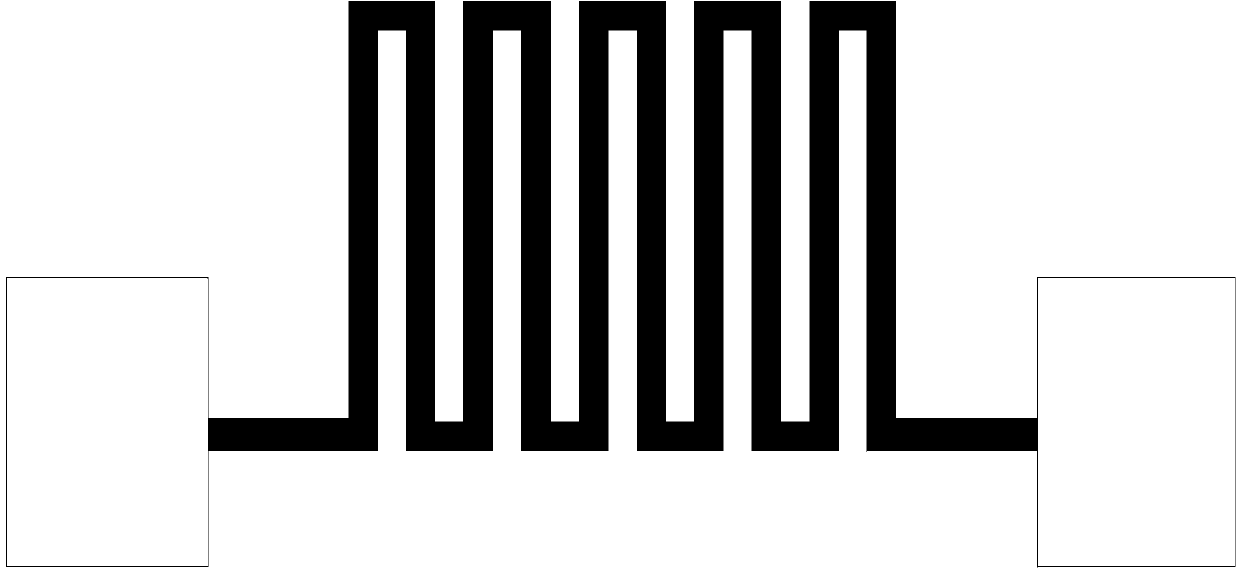

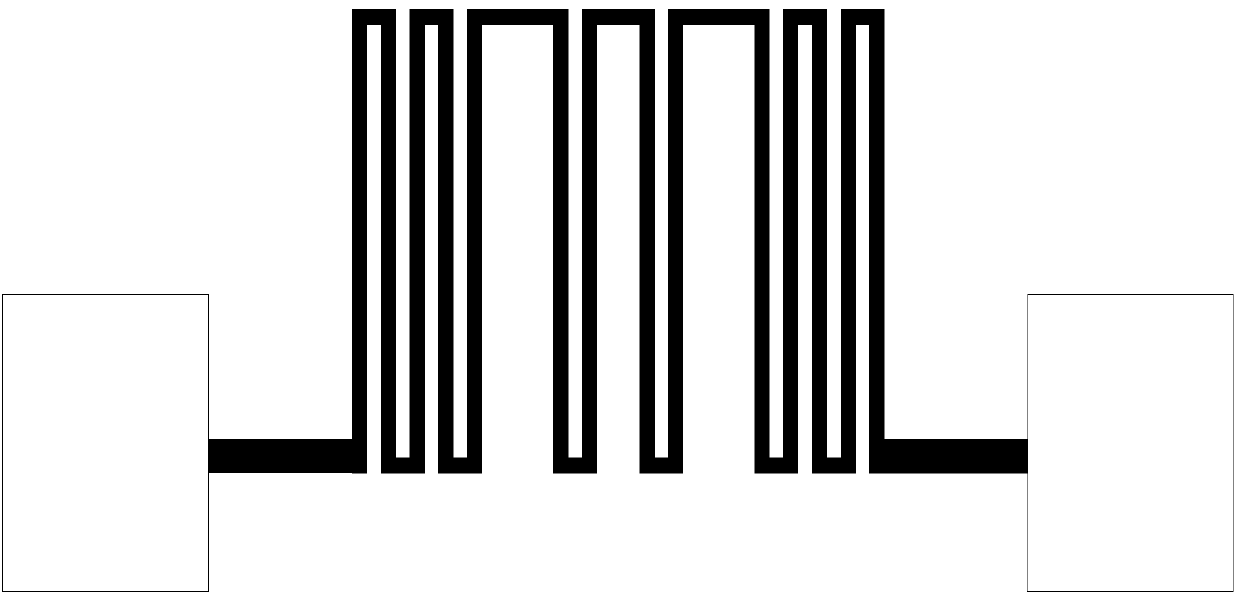

[0039] Specific implementation mode one: combine figure 1 Describe this embodiment mode, the heating type humidity sensor for sonde described in this embodiment mode, it comprises base 1, first insulating layer 2, serpentine heater electrode 8, second insulating layer 9, lower electrode 10, sensor A wet layer 11 and a porous upper electrode 12; wherein, the upper surface of the substrate 1 is laid with a first insulating layer 2; the upper surface of the first insulating layer 2 is provided with a serpentine heater electrode 8;

[0040] The serpentine heater electrode 8 includes a first heater pad 5, a second heater pad 6, a first extraction electrode, a first part of the serpentine electrode, a second part of the serpentine electrode, a third part of the serpentine electrode and the second lead-out electrode;

[0041] One end of the first lead-out electrode is connected to the head end of the first part of the serpentine electrode, the end of the first part of the serpentine...

specific Embodiment approach 2

[0077] Specific embodiment two: this embodiment is the preparation method of the heating type humidity sensor described in specific embodiment one for sonde, and described method comprises the following steps:

[0078] Step 1: preparing the substrate 1 of the sensor, and cleaning the prepared substrate 1 with deionized water;

[0079] Step 2: Oxidize the surface of the substrate 1 prepared in step 1 to form a dense layer of SiO 2 , as the first insulating layer 2;

[0080] Step 3: Obtain the upper surface of the insulating layer in step 2, and prepare the serpentine heater electrode 8 by photolithography and magnetron sputtering;

[0081] Step 4: Prepare Al on the upper surface of the serpentine heater electrode 8 prepared in Step 3 by radio frequency sputtering 2 o 3 protective layer, as the second insulating layer 9;

[0082] Step 5: Prepare the lower electrode 10 on the upper surface of the second insulating layer 9 by photolithography and magnetron sputtering;

[0083...

specific Embodiment approach 3

[0086] Specific embodiment three: this embodiment is a further limitation on the preparation method of the heating humidity sensor for radiosondes described in specific embodiment two. In step one, the substrate 1 is a single crystal with a thickness of 400 μm and a crystal orientation of 100 silicon;

[0087] In step 2, the thickness of the insulating layer is 500nm-1000nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com