Detachable heat exchanger plate bundle composed of all-welded plate tubes

A heat exchanger, dismantling technology, applied in the field of heat exchanger design and manufacturing, can solve the problems of non-disassembly, easy scaling, high working pressure, etc., and achieves the effect of compact structure, small footprint, and easy processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention and its effects will be further described below in conjunction with the accompanying drawings.

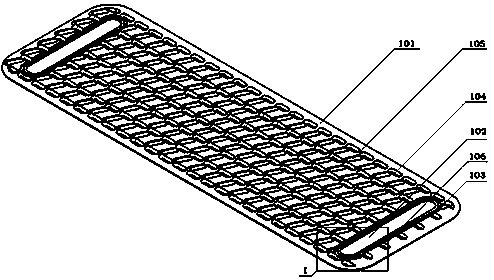

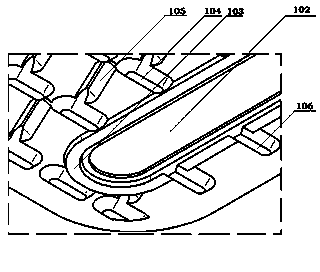

[0025] refer to Figure 1 to Figure 6c , a detachable heat exchanger plate bundle composed of all-welded plate tubes. First, holes are opened near the two opposite sides and near both ends of the corrugated plate sheet 1 to form a medium inlet and outlet 102; then the two corrugated plates are The sheets are stacked together so that the convex corrugations on them are in contact with each other; secondly, the inlay 2 is welded between the two corrugated sheets to form a fully welded sheet tube; again, the sealing gasket groove 103 between the two sheet tubes and at the entrance and exit of the medium Equipped with rubber sealing gasket 3 to form a heat exchanger plate bundle. Finally, the plate bundle is fixed together by means of bolt connection, thereby forming a detachable heat exchanger plate bundle.

[0026] The corrugated sheet 1 is formed by pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com