Electromagnetic oven

A technology of induction cooker and furnace cavity, applied in the field of induction cooker, can solve the problems of high heating of electrical components, poor heat dissipation effect, difficult induction cooker, etc., and achieve the effects of prolonging service life, improving heat dissipation effect and smooth air intake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

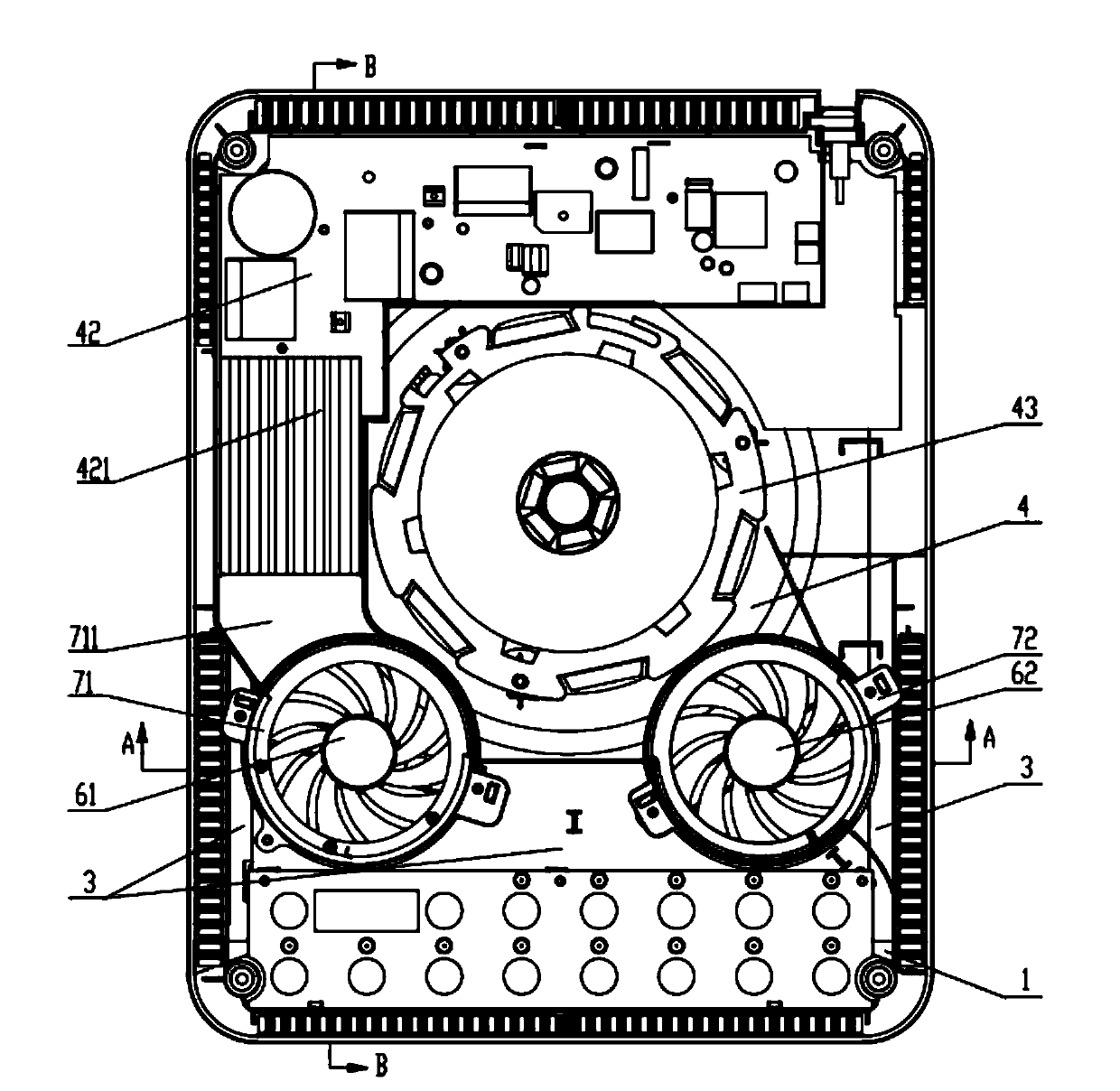

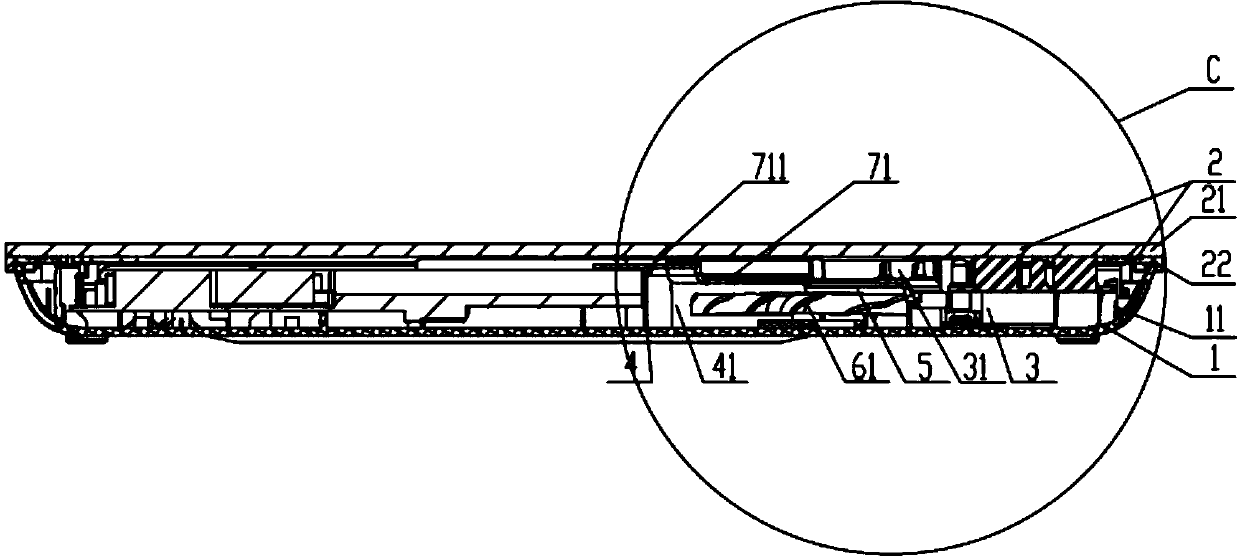

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0042] An induction cooker provided by the present invention comprises a base and an upper cover assembly, the base and the upper cover assembly form a furnace chamber, a fan is arranged in the furnace chamber, a fan cover is arranged on the periphery of the fan, a windshield rib is arranged on the base, the fan cover and The two sides of the windshield ribs respectively form a cold air chamber and a heating chamber; the side wall of the cold air chamber is provided with a side air inlet for the cooling air to enter the cold air chamber, and the side wall of the heating chamber is provided with a side outlet for the cooling air to exit the heating chamber tuyere.

[0043] The cooling air first enters the cold air chamber from the outside of the induction cooker through the side air inlet on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com