Novel height-adjustable silent drain valve structure fast to replace or maintain

A drain valve and height technology, applied in the field of silent drain valve structure, can solve the problems of matching and repairing heavy workload, toilet flushing performance decline, and inability to adjust, etc., to achieve after-sales service efficiency improvement, flushing performance improvement, quick repair Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

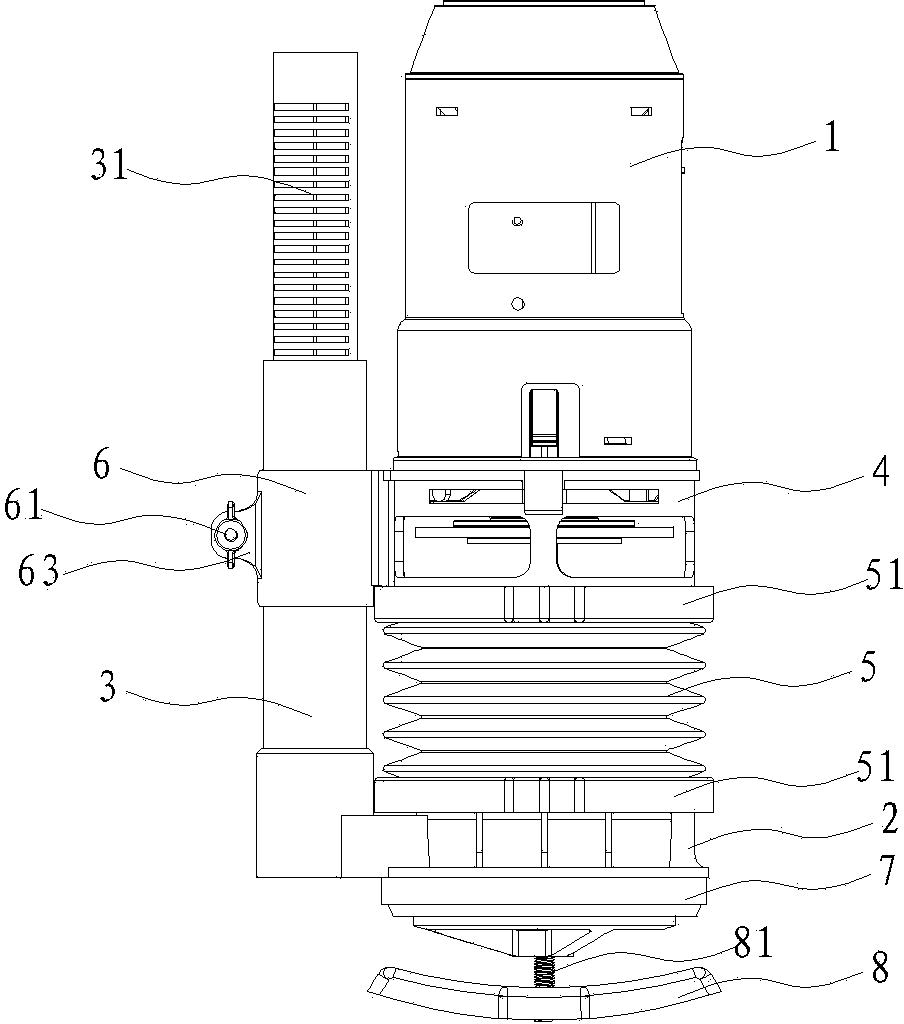

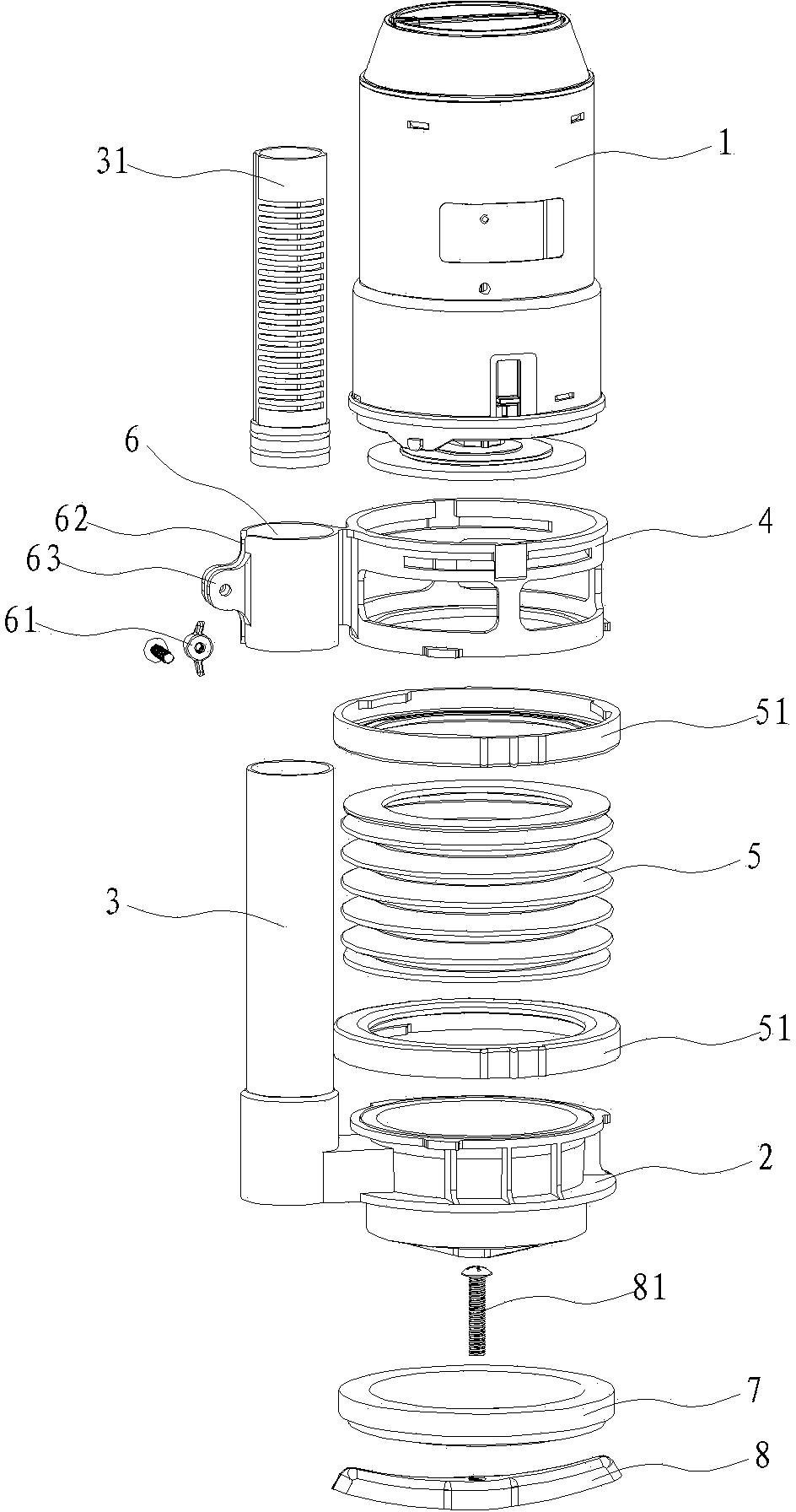

[0013] refer to figure 1 , figure 2 , this embodiment provides a novel height-adjustable, quick-replaceable silent drain valve structure, including a drain valve body 1, a drain base 2 for fixing to the toilet tank, and a drain base located below the drain valve body 1 2 connected overflow pipe 3, a hollow drainage connection seat 4 is provided between the drain valve body 1 and the drainage base 2, and a sealing air bag 5 is provided between the drainage connection seat 4 and the drainage base 2, and the sealing air bag The upper and lower ends of 5 are respectively provided with connecting nuts 51, and the sealing airbag 5 is respectively connected with the drainage connecting seat 4 and the drainage base 2 through two connecting nuts 51, and the described drainage base 2 and the drainage connecting seat 4 cooperate with the sealing airbag 5 A r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com