Oil charge buffering device of hydraulic gear-shifting gearbox clutch

A buffer device and clutch technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve problems such as large shift shocks, and achieve the effects of reducing shift shocks, quick oil return, and smooth integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

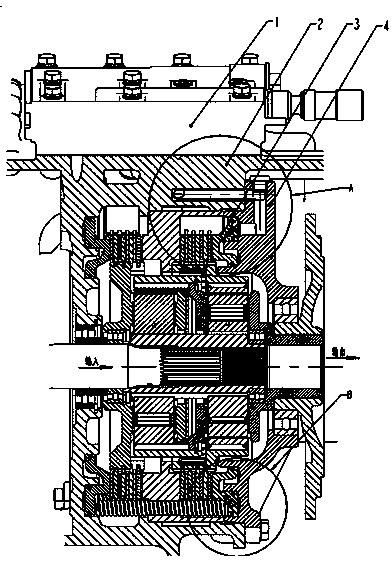

[0024] Such as figure 1 As shown, the casing 2 is fixed with an outer oil cylinder body 4, and the outer piston 3 cooperates with the outer oil cylinder body 4 to form an outer oil cylinder C. The outer piston 3 provides the clutch power of the clutch. The outer oil cylinder body 4 is provided with a ring-shaped groove, the outer piston 3 is provided with a ring-shaped boss, and the ring-shaped groove on the outer cylinder block 4 cooperates with the ring-shaped boss of the outer piston 3 to form an inner cylinder D; the outer cylinder Between the oil chamber of the outer oil cylinder of the cylinder body 4 and the oil chamber of the inner oil cylinder, a buffer control circuit composed of a check valve II and a damping valve I in parallel is arranged, and the check valve II is set as the check valve II when filling oil The oil is blocked when the lock is locked, and the oil is passed when the gear is off.

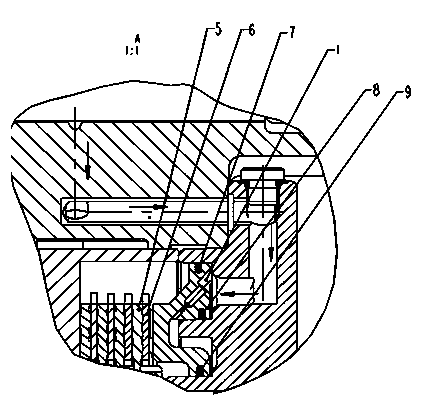

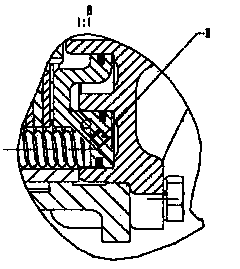

[0025] Such as figure 1 , 2 , 3, 5, 6, and 7, the innermost ring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com