Circulating type hydraulic oil tank structure and use method thereof

A hydraulic oil tank and hydraulic oil technology, which is applied in the direction of oil supply tank devices, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problem of reducing the service life of hydraulic components and oil, system collapse, and oil pollution, etc. problem, achieve the effect of reducing the chance of entering the fuel tank, cooling evenly and stably, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

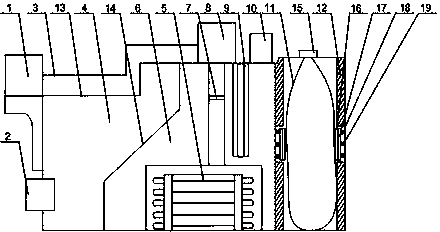

[0020] Such as figure 1As shown, the present invention is a circulating hydraulic oil tank structure and its use method. The high-temperature hydraulic oil enters the oil return chamber 6 through the oil guide pipe 3 after being cooled by the cooler 1 for the first time, and the sediment in the hydraulic oil is filtered It flows into the hydraulic oil cooler 15 under the filtering effect of the filter. Since the hydraulic oil still has a certain residual temperature in the first cooling, the residual heat will affect the transmission efficiency when the hydraulic oil enters the transmission parts. After the second cooling effect of the cooler 15, the liquid level of the hydraulic oil begins to rise in the oil return chamber 6; at this time, the volume change of the hydraulic oil in the oil tank needs to be realized by exchanging the gas with the external environment, but the external pollution The air bag 11 set in the oil return chamber 6 can return to the oil return chamber ...

Embodiment 2

[0022] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the tank body 13 is provided with an oil filling port 10 , and the oil filling port 10 communicates with the upper end of the oil return chamber 6 . In order to avoid the situation that the volume change of the air bag 11 is not enough to make up for the volume change in the oil return chamber 6 when the total amount of hydraulic oil in the oil tank is lower than the standard oil volume, an oil filling port 10 is provided on the tank body 13, and the oil filling port 10 is connected with the upper end of the oil return chamber 6, so that the staff can inject new hydraulic oil into the oil return chamber 6 in time to keep the pressure in the oil return chamber 6 stable and ensure the oil tank to circulate oil smoothly.

Embodiment 3

[0024] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, a magnetic filter screen 7 is installed in the oil return cavity 6, and the magnetic filter screen 7 is located between the hydraulic oil cooler 15 and the oil return filter 8 between. During the long-term working process of the hydraulic system, certain wear and tear will occur between the parts, and the fine debris generated by the wear will return to the oil return chamber 6 together with the hydraulic oil, which will damage the hydraulic system during repeated use. The working efficiency of the machine has a significant impact. The installed magnetic filter screen 7 can collect the metal debris generated, reduce the impact on the components in the hydraulic system, and improve the effect of hydraulic transmission.

[0025] As a preference, when the electric air valve is connected with the pressure sensor 17, it can more flexibly adjust the injection amount of air, and improve the working e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com