Sun-shading plate compactor

A technology of plate compaction and sun visor, which is applied to roads, road repairs, roads, etc., and can solve the problems of physical hazards for workers, easy to stir up dust, and easy heat stroke for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is described in further detail, but structure of the present invention is not limited to following embodiment:

[0018] 【Example】

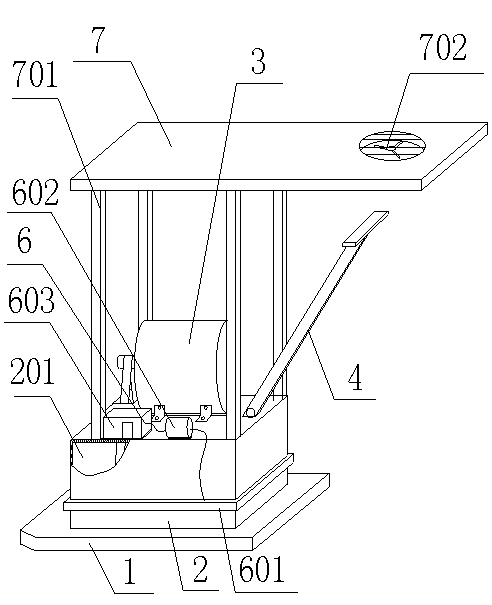

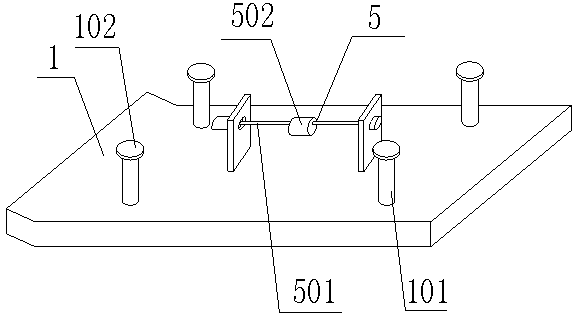

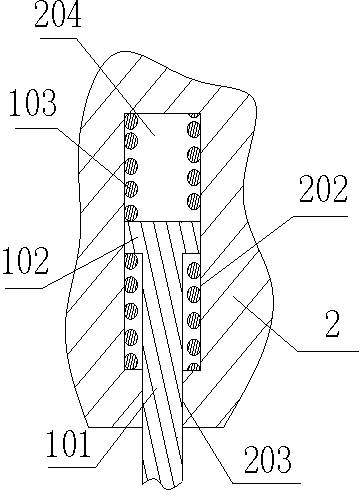

[0019] like Figure 1-4 As shown, the sunshade plate compactor includes a pressing plate 1, a box body 2 installed on the upper end of the pressing plate 1, a driving mechanism 3 installed on the top of the box body 2, a handrail 4, and an opening at the lower end of the box body 2, which forms a unit with the pressing plate 1. In a confined space 201, a vibrating body 5 is arranged on the upper end surface of the pressing plate 1, and the vibrating body 5 is driven by the driving mechanism 3 to work. The pressing plate 1 is in a square shape, and a mounting column 101 is arranged at each of its four corners, and the box body 2 corresponds to the mounting column 101 is provided with a mounting hole 202, the mounting hole 202 is a stepped hole, and the lower end is a small hole 203,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com