Energy-saving and environmentally friendly composite floor and manufacturing method thereof

A composite flooring, energy-saving and environmental-friendly technology, applied in chemical instruments and methods, wood layered products, building structures, etc., can solve problems such as poor surface flatness, affecting appearance and performance, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

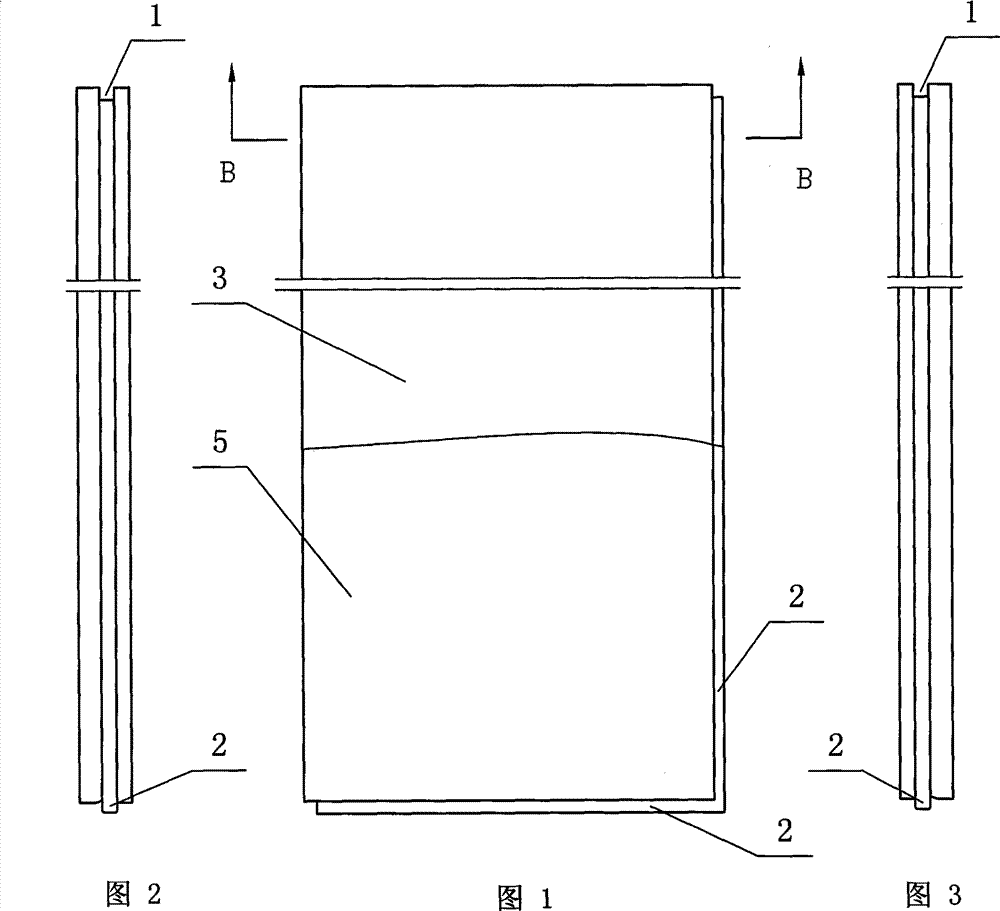

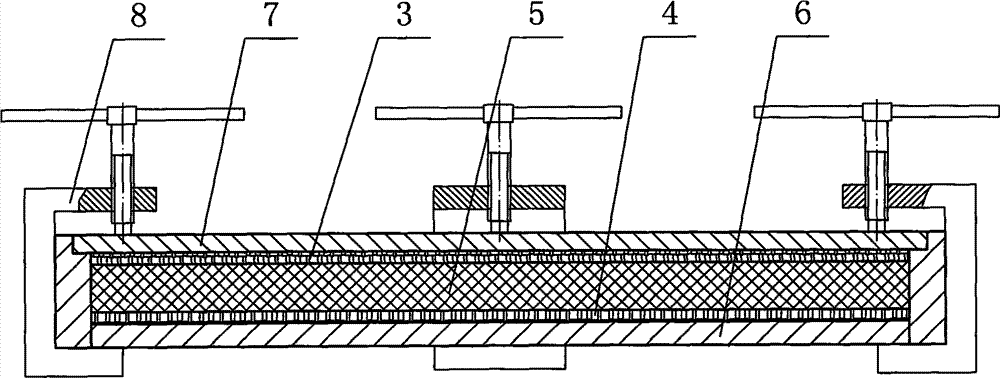

[0023] Figure 1 to Figure 4 It is a schematic diagram of the structure of an energy-saving and environmentally friendly composite floor. It can be seen from the figure that it is a long strip floor with mutually spliced mortise 1 or tongue 2 on both sides of its long and short sides. The panel 3 on the upper surface of the floor and the base plate 4 on the lower surface are made of wood veneers with a thickness of 1-4 mm. Between the face plate 3 and the bottom plate 4 is a core plate 5, and the core plate 5 is made of polyurethane foam material. The density of polyurethane foam material is 300-400Kg / m 3 .

[0024] The manufacture method of above-mentioned energy-saving and environment-friendly composite floor is:

[0025] (1) slice the log into a panel 3 and a base plate 4 with a thickness of 1 to 4 millimeters with a planer, leave a tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com