Technology for producing middle base plate by using waste cotton, waste paper and waste slurry slag

A production process and technology of waste paper pulp, applied in the field of papermaking, can solve the problems of unaffordable processing costs, environmental pollution, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

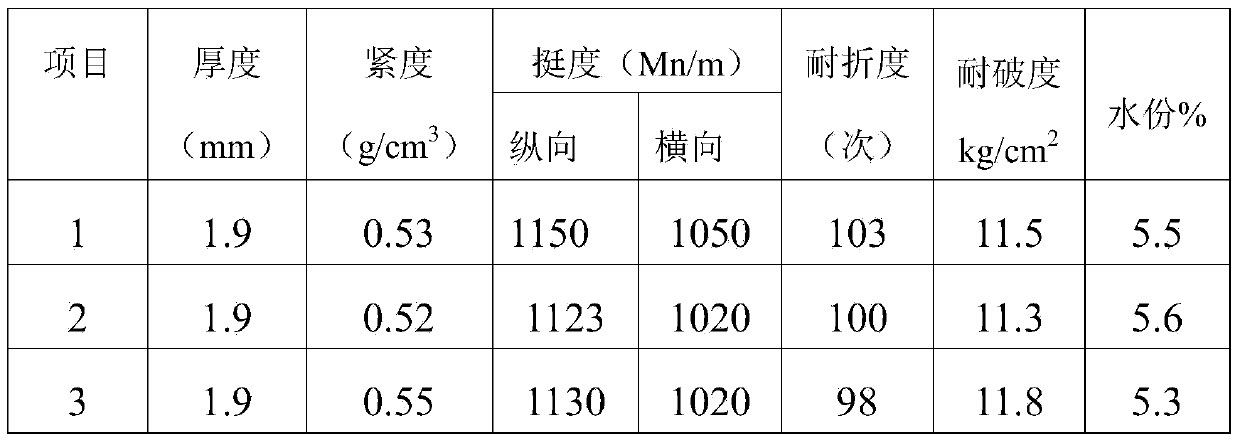

Examples

Embodiment 1

[0019] Extraction of waste fiber from waste pulp residue: Use a pump to pump waste from the bottom of the sedimentation tank to the storage tank, add 0.15% disinfectant to the tank, and circulate evenly. The concentration of waste slurry reaches 3.9%.

[0020] Removal of waste cotton and waste paper: manually select out the sundries that cannot be used to produce mid-sole boards from the purchased waste paper, such as plastics, flat ribbons, braided belts, iron wires, cans, beverage bottles, and waste CDs. The selected waste cardboard is sent to the workshop for use.

[0021] Disintegration and disintegration of waste paper: transport the selected waste cardboard to a low-consistency hydraulic shredder for disintegration. The pulp concentration after disintegration is 3.5%. Defibrication is carried out on the double-disk mill, and the degree of beating of the cardboard pulp after defibrication is controlled at 22 degrees.

[0022] Mixing and coloring of waste: mix waste cott...

Embodiment 2

[0029] Extraction of waste fiber from waste pulp and residue: Use a pump to pump waste from the bottom of the sedimentation tank to the storage tank, add 0.15% disinfectant to the tank, and circulate evenly. The concentration of waste slurry reaches 4%.

[0030] Removal of waste cotton and waste paper: manually select out the sundries that cannot be used to produce mid-sole boards from the purchased waste paper, such as plastics, flat ribbons, braided belts, iron wires, cans, beverage bottles, and waste CDs. The selected waste cardboard is sent to the workshop for use.

[0031] Disintegration and disintegration of waste paper: transport the selected waste cardboard to a low-consistency hydraulic shredder for disintegration. The pulp concentration of the disintegrated paperboard is 3.8%, and the disintegrated paperboard pulp is pumped with pulp Go to the double disc mill for deflaking, and the degree of beating of the cardboard pulp after deflaking is controlled at 23 degrees....

Embodiment 3

[0039] Extraction of waste fiber from waste pulp and residue: Use a pump to pump waste from the bottom of the sedimentation tank to the storage tank, add 0.15% disinfectant to the tank, and circulate evenly. The concentration of waste slurry reaches 4.0%.

[0040] Removal of waste cotton and waste paper: manually select out the sundries that cannot be used to produce mid-sole boards from the purchased waste paper, such as plastics, flat ribbons, braided belts, iron wires, cans, beverage bottles, and waste CDs. The selected waste cardboard is sent to the workshop for use.

[0041] Disintegration and disintegration of waste paper: transport the selected waste cardboard to a low-consistency hydraulic shredder for disintegration. The pulp concentration of the disintegrated paperboard is 3.6%, and the disintegrated paperboard pulp is pumped with pulp Go to the double disc mill for deflaking, and the degree of beating of the cardboard pulp after deflaking is controlled at 22 degrees....

PUM

| Property | Measurement | Unit |

|---|---|---|

| beating degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com