Novel continuous bar material chromium plating production line

A production line and bar technology, applied in the field of new bar continuous chrome plating production line, can solve the problems of unevenness, reduce equipment productivity, easy connection loosening, etc., and achieve the effect of uniform coating thickness, easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

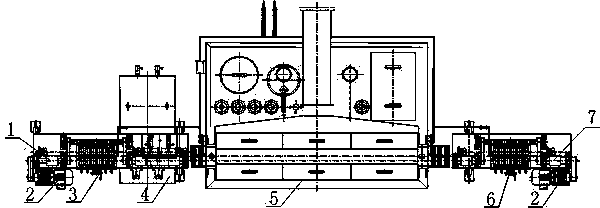

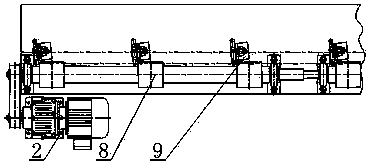

[0021] Such as figure 1 , 2 As shown, a new continuous chrome-plating production line for bars includes an automatic feeding device 1, a first cathode device 3, an activation device 4, a chrome plating tank 5, a second cathode device 6 and an automatic unloading device 7, and the automatic feeding device 1 And the automatic unloading device 7 comprises the active driving device and the passive driving device on the frame and the installation frame, the active driving device is made up of two roller tables arranged in parallel, and each roller table is composed of several active driving devices installed thereon. The driving shaft of the driving roller 8 is formed in series, and the passive driving device is composed of passive driving rollers 9 arranged at intervals above the roller table along the direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com