Composite polyphenyl thioether material

A technology of composite materials and polyphenylene sulfide, applied in the field of polymer materials, can solve the problems of low tracking index, little improvement in impact toughness, and inapplicability for manufacturing thin-walled parts.

Active Publication Date: 2014-12-10

南京真宸科技有限公司

View PDF4 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the impact toughness of the material has not been greatly improved, and the tracking index of the material itself is relatively low, generally less than 150V. In order to expand its application range, it is necessary to improve its impact performance and tracking index

[0004] Chinese patent CN1462771 uses nano-styrene-butadiene rubber to modify polyphenylene sulfide. This patent is mainly used for the preparation of pure glass fiber reinforced polyphenylene sulfide composite materials. Since the addition of rubber reduces the fluidity of the material, it is not suitable for thin-walled molding. parts

Similarly, Chinese patent CN1513914 proposes the use of olefin resin and polyphenylene sulfide to form a polyphenylene sulfide composition, which is also not suitable for the manufacture of thin-walled parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The following examples will further describe the present invention in detail, but the present invention should not be limited by these examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

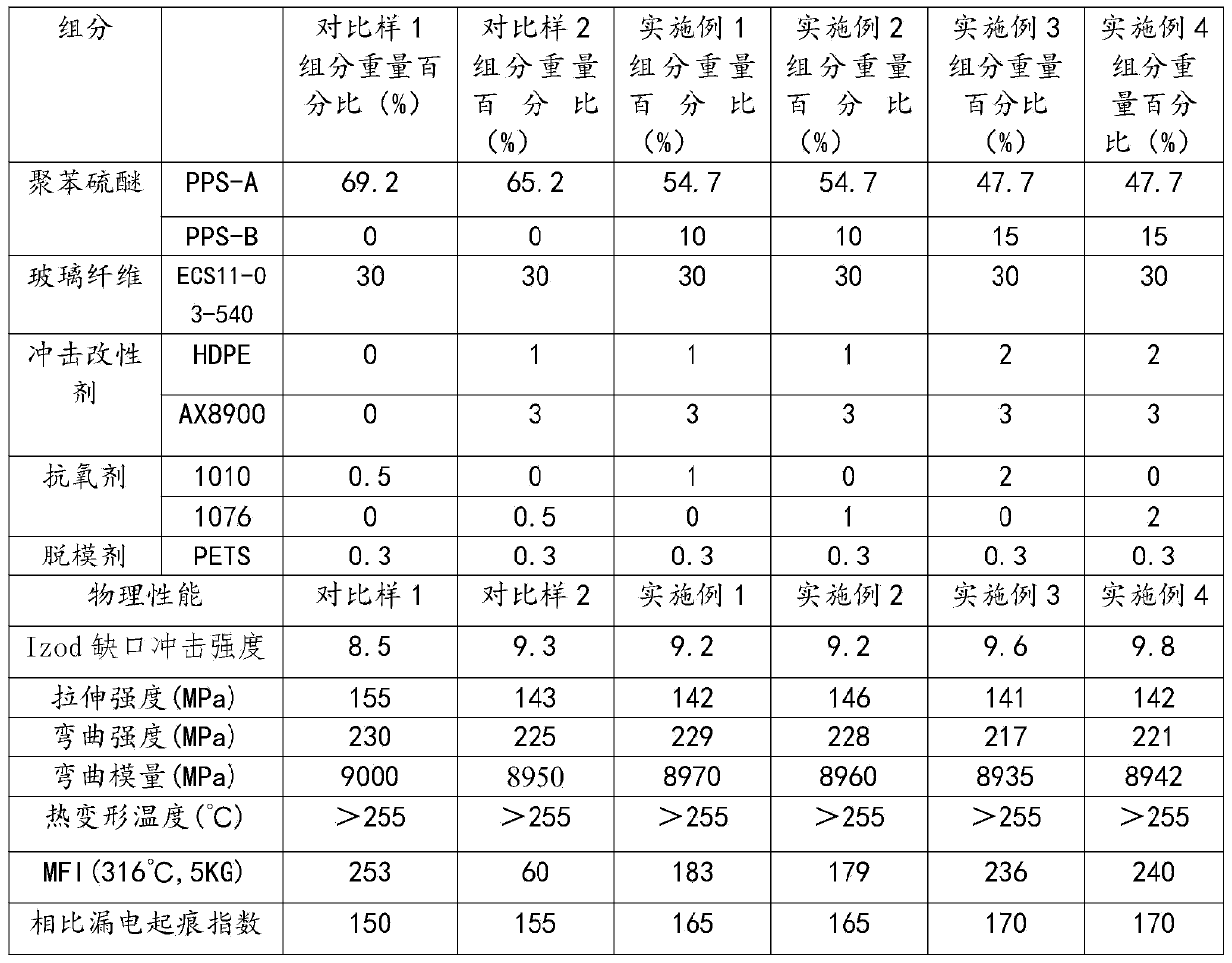

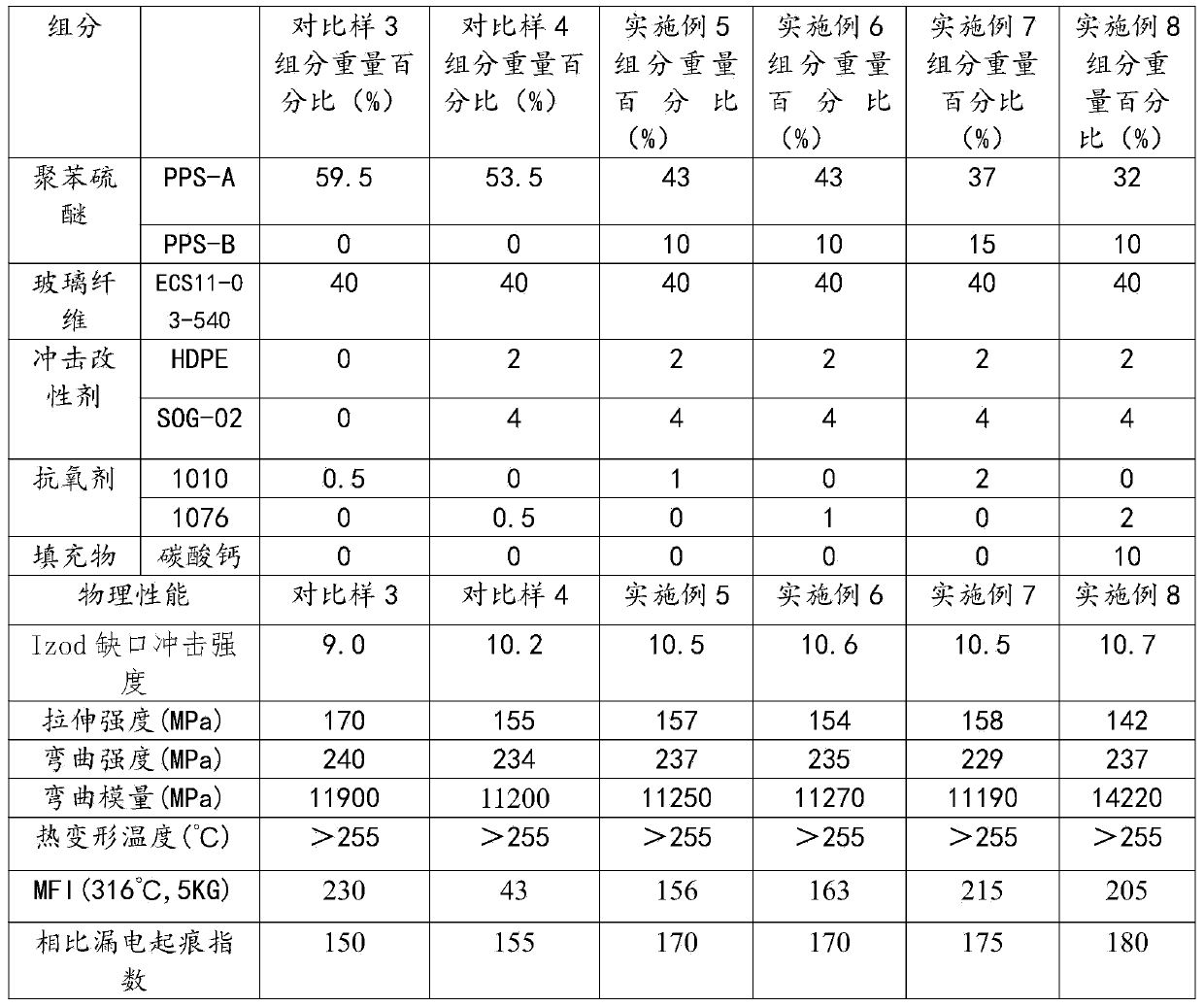

The invention provides a composite polyphenyl thioether material. The composite material consists of the following components by weight percent: 40-80% of polyphenyl thioether, 20-50% of glass fiber, 3-10% of an impact modifier, and 1-2% of an antioxidant. The composite polyphenyl thioether material has favorable impact property, heat resistance and higher comparative tracking index, at the same time, the composite polyphenyl thioether material has higher flowability, and the composite polyphenyl thioether material is suitable for manufacturing electrical and electronic products, mechanical products, automobile parts and other heat-resistant and corrosion-resistant products.

Description

technical field [0001] The invention relates to the technical field of polymer materials, in particular to a polyphenylene sulfide composite material. Background technique [0002] Polyphenylene sulfide (PPS), also known as polyphenylene sulfide and polyphenylene sulfide, is a new type of special engineering plastic that was first created and put into production by Phillips Petroleum Co of the United States in 1968. Due to its special molecular structure, it has many unique properties, mainly in: excellent thermal stability, chemical stability, dimensional stability, corrosion resistance, good bonding performance, excellent flame retardancy, good Electrical properties, blendable modification. At present, it has a wide range of applications in automobile manufacturing, electrical and electronic, chemical, instrumentation and aerospace industries. [0003] Due to the existence of a large number of benzene rings on the main chain of PPS, the rigidity of the material is increa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L81/02C08L23/06C08L23/08C08L51/06C08K7/14

Inventor 郭建明王港陈晓媛于庆顺杨建军

Owner 南京真宸科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com