Preparation method of nylon powder for 3D (three-dimensional) printing

A nylon powder and 3D printing technology, applied in the field of nylon powder preparation, can solve the problems of long powder production cycle, high process control requirements, difficult mass production, etc., and achieve the effect of meeting performance requirements, uniform particle size distribution, and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A kind of preparation method of the nylon powder that is used for 3D printing of the embodiment of the present invention, it comprises the following steps:

[0016] S1. Nylon modification: put the nylon 12 base material into the mixer, spray and add additives to the nylon 12 base material, the additives are surfactants, light absorbers, compatibilizers, Adhesive, antioxidant and heat conduction powder, the nylon 12 base material and additives are stirred evenly, and then dried to obtain the modified nylon base material.

[0017] Nylon 12 is chemically known as polylaurolactam. Using high-speed stirring to modify the nylon 12 base material, so that various additives can be attached to the surface of the powder without high-temperature melting, and the modification effect is obvious.

[0018] Optionally, the surfactant is sodium dodecylbenzenesulfonate. The light absorber is 2-(2-hydroxy-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole (English name is UV327). The compat...

Embodiment 1

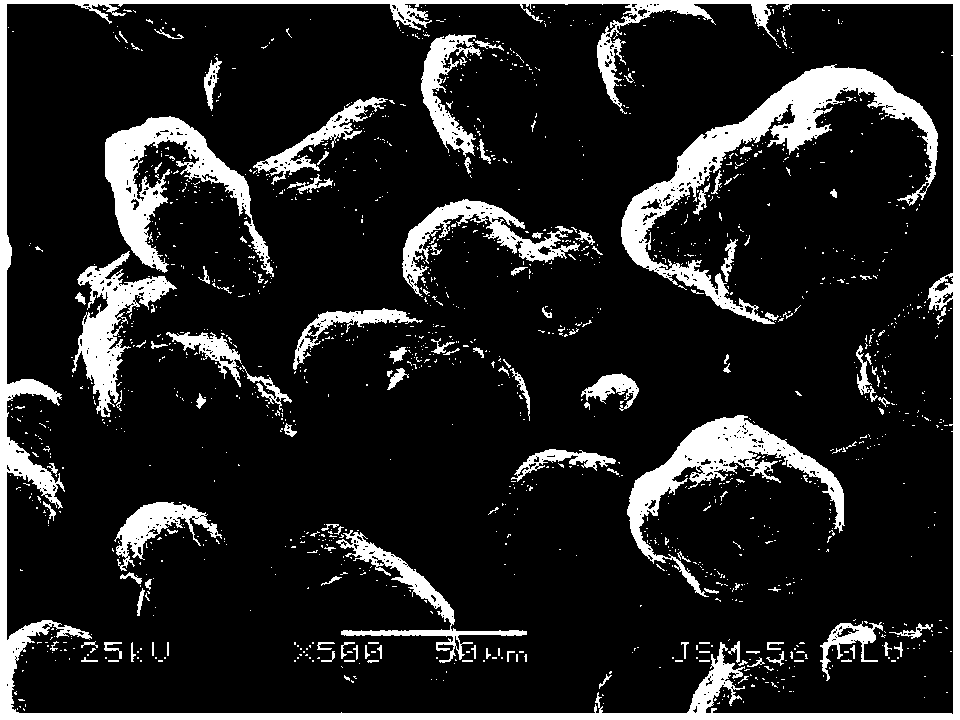

[0027] Put the nylon 12 base material into a mixer, add surfactant, light absorber, compatibilizer, viscosity reducer, antioxidant and heat conduction powder, stir evenly and then dry to obtain the modified nylon base material; Add the modified nylon base material, solvent oil and emulsifier into the reaction kettle, stir and heat to 200°C to melt the modified nylon base material into a liquid, stir and emulsify at high speed for 30 minutes to form a high-temperature nylon emulsion at a speed of 500 rpm; Cool quickly to form a nylon suspension, and undergo solid-liquid separation, washing, drying, and grading and sieving to obtain spherical nylon powder for 3D printing. The average particle size of the nylon powder is 57.6 μm.

Embodiment 2

[0029] Put the nylon 12 base material into a mixer, add surfactant, light absorber, compatibilizer, viscosity reducer, antioxidant and heat conduction powder, stir evenly and then dry to obtain the modified nylon base material; Add the modified nylon base material, solvent oil and emulsifier into the reaction kettle, stir and heat to 180°C to melt the modified nylon base material into a liquid, stir and emulsify at high speed for 20 minutes to form a nylon high-temperature emulsion at a speed of 1500 rpm; put the nylon high-temperature emulsion Cool quickly to form a nylon suspension, and undergo solid-liquid separation, washing, drying, and grading and sieving to obtain spherical nylon powder for 3D printing. The average particle size of the nylon powder is 63.7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution range | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com