Manufacturing process of alkalescent mountain spring water

A production process and technology of mountain spring water, which is applied in the field of production process of weak alkali mountain spring water, can solve the problems of poor stability, many ore impurities in water, and poor taste, and achieve good stability, no sediment, and slightly sweet taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

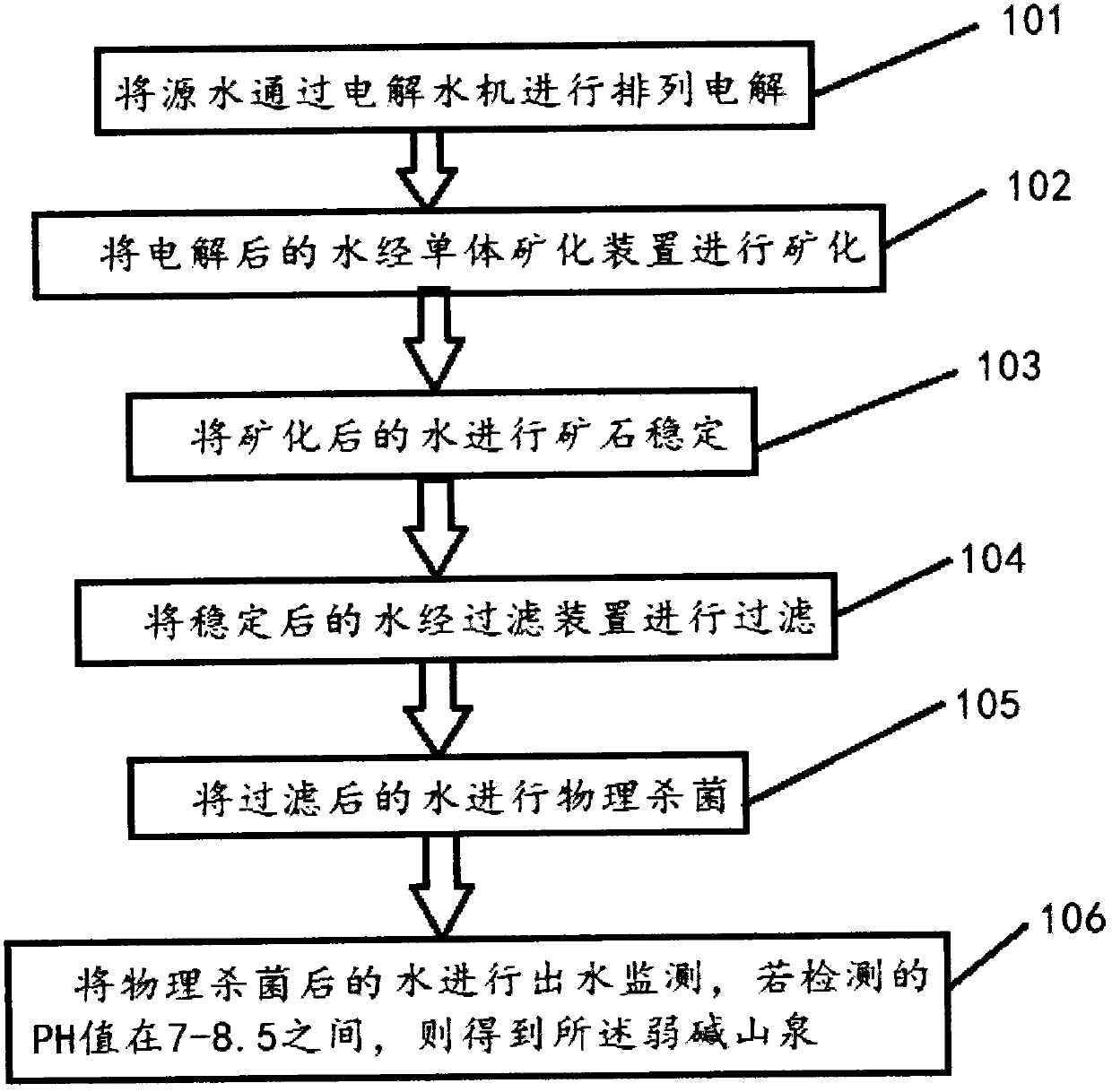

[0016] Such as figure 1 Shown is a production process of a kind of weak alkali mountain spring water provided by this embodiment, which includes the following steps: 101, the source water is subjected to electrolysis through an electrolytic water machine; 102, the electrolyzed water is mineralized through a single mineralization device 103, ore stabilization of the mineralized water; 104, filtering the stabilized water through a filter device; 105, physically sterilizing the filtered water; 106, monitoring the effluent of the physically sterilized water, If the detected pH value is between 7-8.5, the weakly alkaline mountain spring water is obtained.

[0017] After the source water is collected from mountains, rivers and lakes, the source water is arranged and electrolyzed to reduce the hardness and softening degree of the source water. Then mineralize the electrolyzed water, add calcium ions and magnesium ions to the water; then stabilize the ore in the water to neutralize t...

Embodiment 2

[0020] A production process of weakly alkaline mountain spring water, comprising the following steps: arranging and electrolyzing source water through an electrolyzed water machine; mineralizing the electrolyzed water through a single mineralization device; and stabilizing the mineralized water; Filter the stabilized water through a filter device; physically sterilize the filtered water; monitor the effluent of the physically sterilized water, and if the detected pH value is between 7-8.5, the weak alkali mountain spring water is obtained .

[0021] Further, before the source water is electrolyzed, the source water needs to be monitored. Specifically, the pH value of the source water collected from the water source may be between 3 and 12. Source water with different pH values will have a certain impact on the produced weakly alkaline mountain spring water. Therefore, it is necessary to monitor the pH value of the source water in real time.

[0022] Preferably, the content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com