Vertical machining device and method for small-caliber PCCP

A processing device and small-diameter technology, applied in the direction of grinding devices, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult layout, small diameter of inner mold, high cost, etc., and achieve the effect of exquisite design, not easy to block, and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

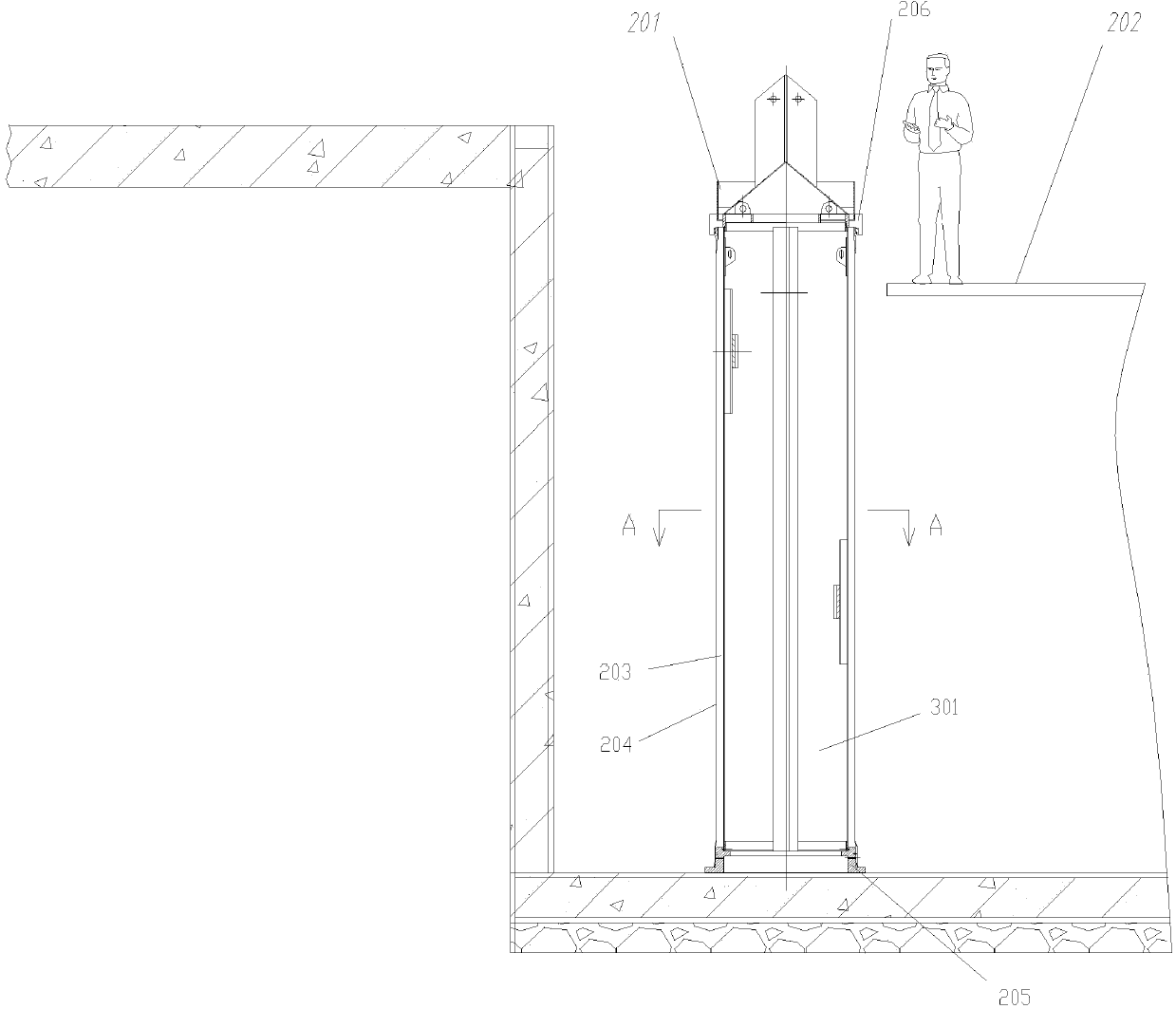

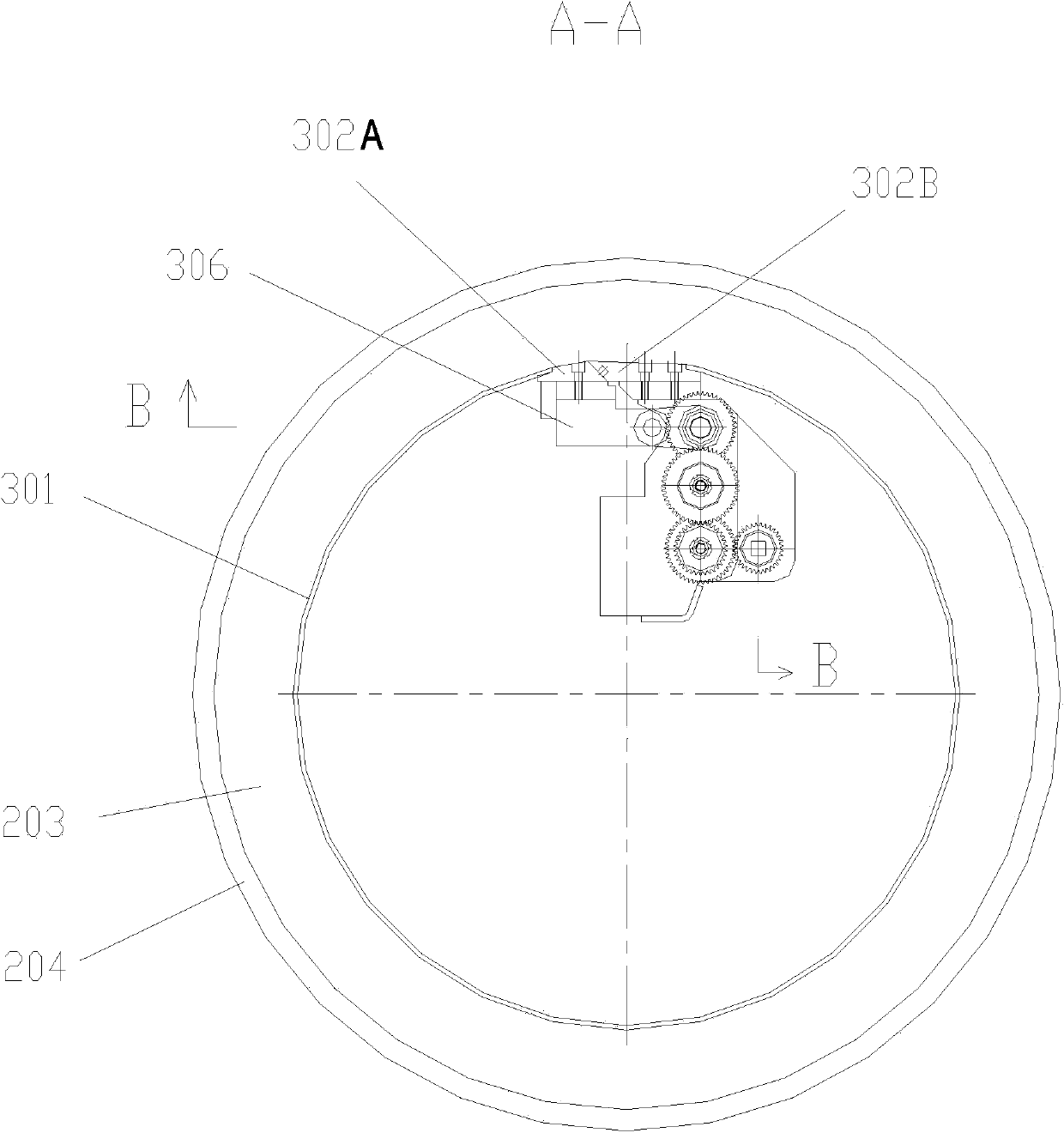

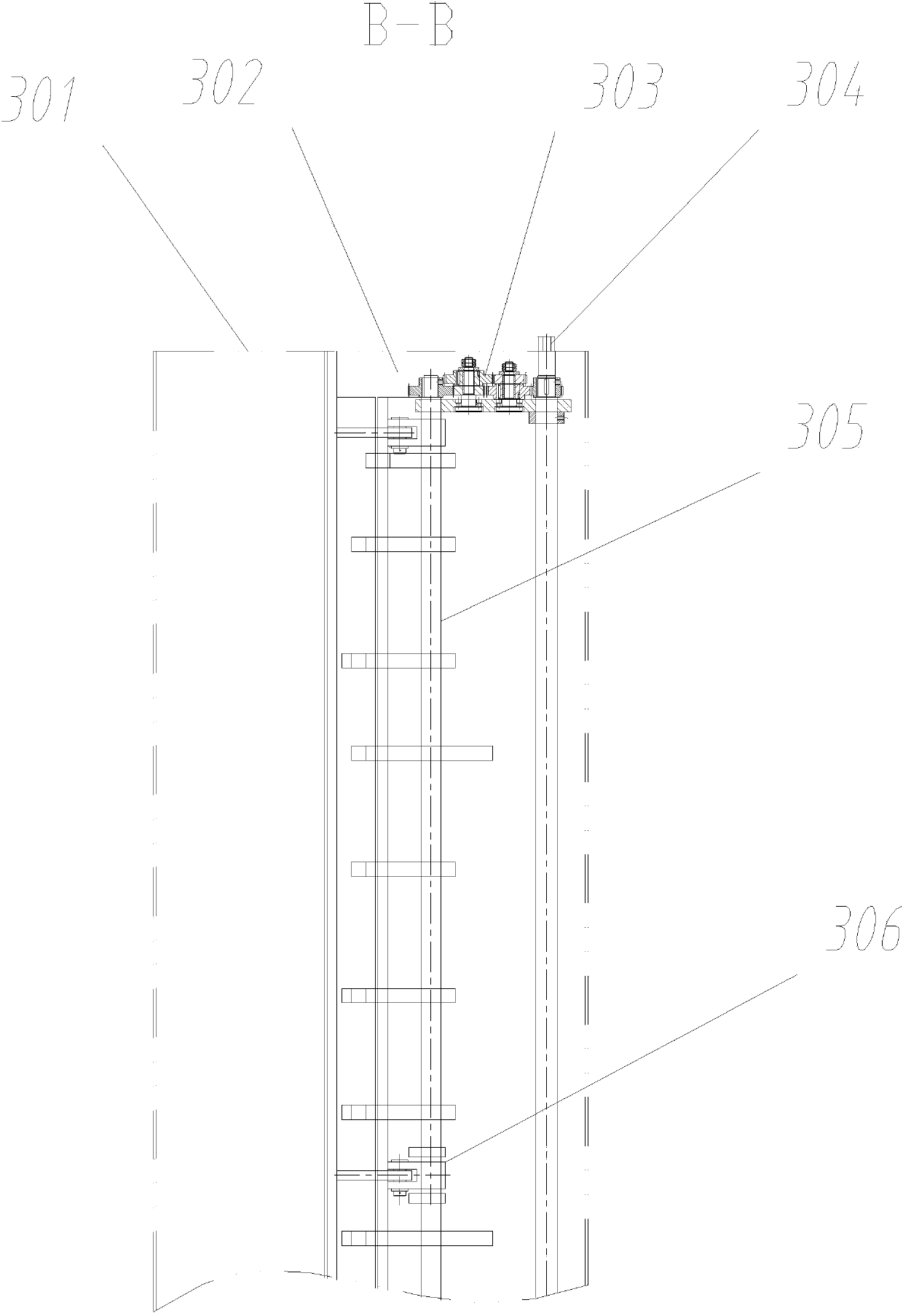

[0046] The present invention as Figure 1-9 As shown: it includes a vertical inner mold 301, an outer mold 204 and a pouring device. The inner mold 301 is provided with an axial straight seam that runs through the height of the inner mold 301, and the two seams of the straight seam are respectively fixedly connected with movable door panels. 302A and the driven door panel 302B; when the inner mold 301 is in the contracted state (out of circle, and the circumference size is smaller than the inner diameter of the tube core 203), the movable door panel 302A is more biased towards the center of the circle, and the movable door panel 302A uses the door panel The hypotenuse pushes the driven door panel 302B until the rated stroke is reached. At this time, the cross section of the inner mold is in a perfect circle state, and the outer diameter of the inner mold 301 is equal to the inner diameter of the tube core 203. In order to ensure that the movable door panel 302A and the driven d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com