One-piece-type vamp and manufacturing method thereof

A production method and a technology for shoe uppers, which are applied to shoe uppers, footwear, heel pads and other directions, can solve the problems of poor ventilation, high cost, labor and low efficiency, etc., to improve production efficiency, smooth flow lines, and save labor. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

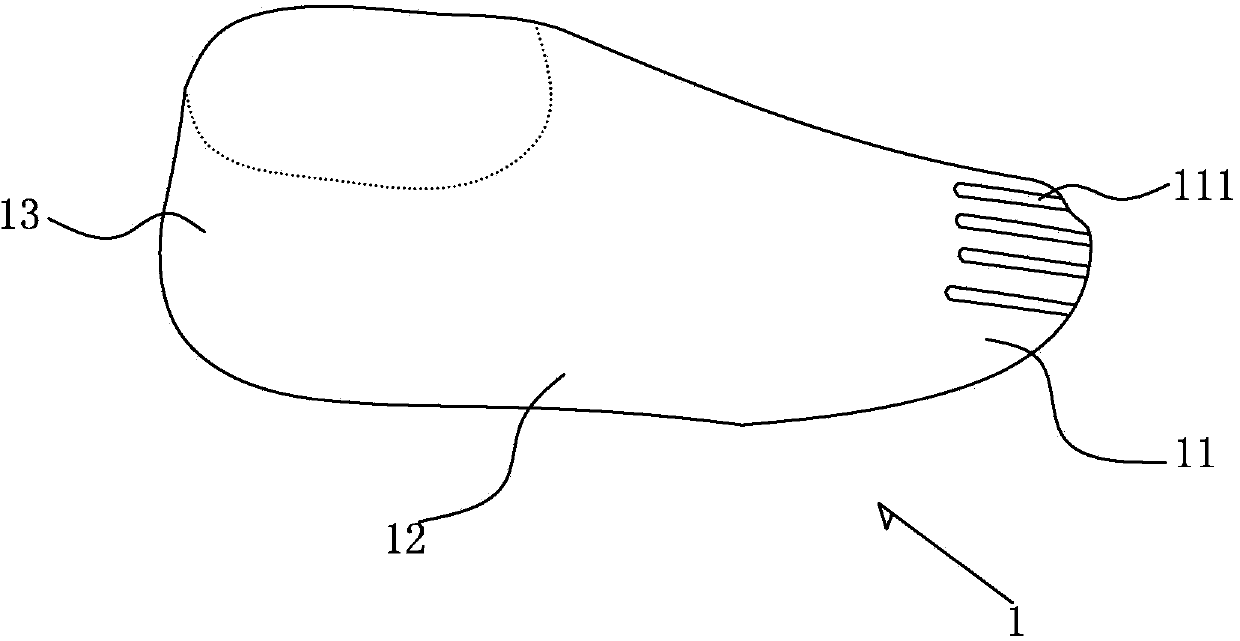

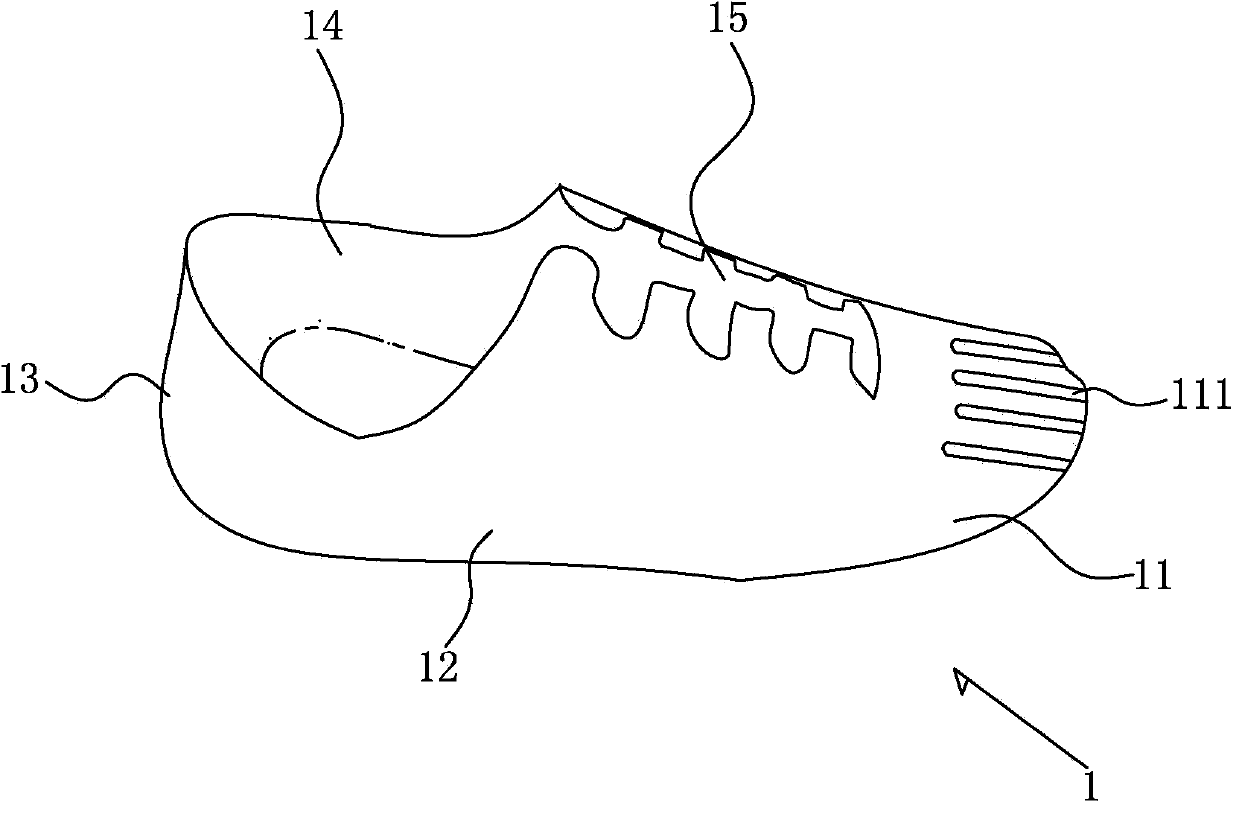

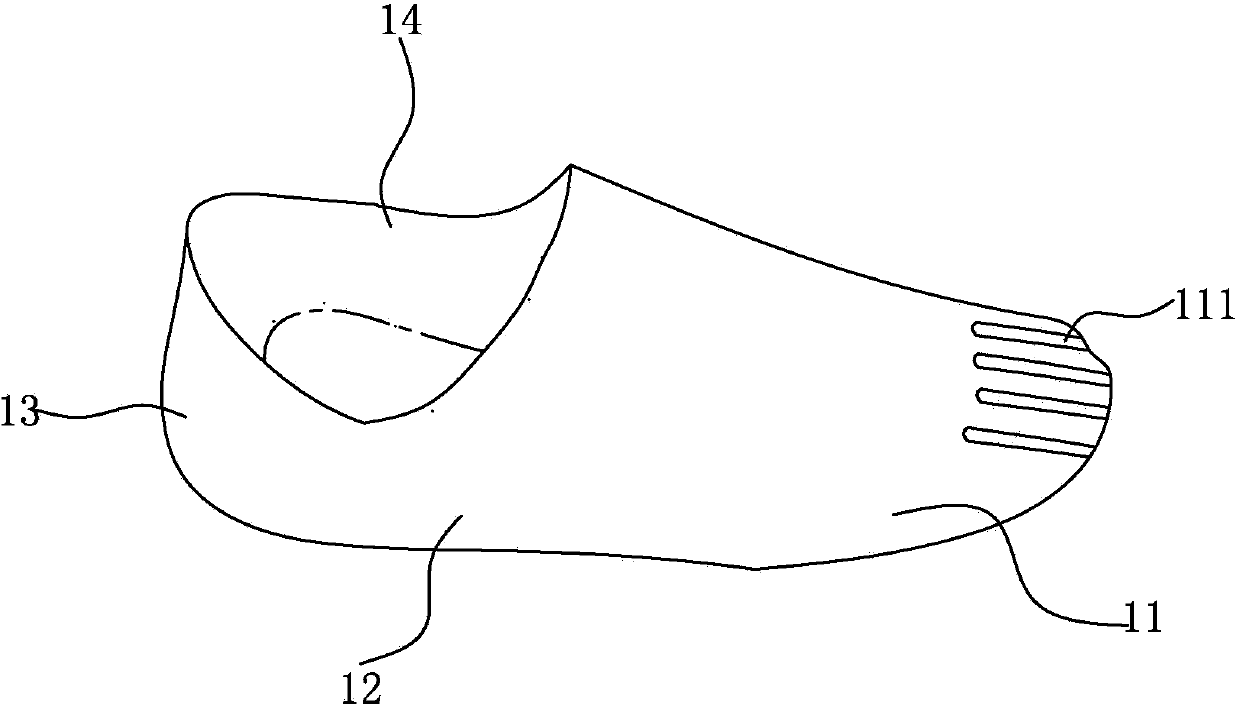

[0031] See Figure 1-2 As shown, the one-piece vamp, the vamp 1 includes: the upper 11, the upper 13 and the waist 12, the upper 11, the upper 13 and the waist 12 are integrally formed in one piece , the front upper 11, the rear upper 13 and the waist 12 are formed by at least three layers of flexible materials, and the upper 1 is integrally formed into a hollow shell that matches the human foot, and the bottom of the upper 1 is connected with a sole.

[0032] Specifically, the vamp 1 is integrally hot-pressed from the sponge layer 101, the upright cotton layer 102 and the cloth layer 103 arranged on both sides of the sponge layer 101, and forms a hollow shell that fits the human foot after molding. . Through other mechanical devices, a shoe opening 14 is provided on the vamp 1 for the feet to penetrate. An opening 15 for connecting a shoe tongu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com