Tunnel-type vegetable microwave dryer and its automatic anti-no-load method

A dryer and tunnel-type technology, which is applied in the field of tunnel-type vegetable microwave dryer and its automatic no-load prevention, can solve the problems of bare conveyor belt leakage, damage to magnetrons, and burning conveyor belts, etc., so as to improve quality, The effect of preventing local microwave energy concentration and no-load operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and example.

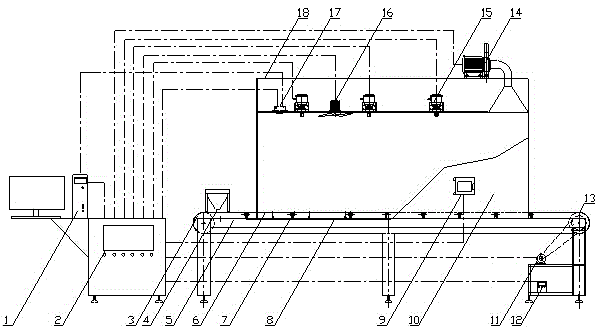

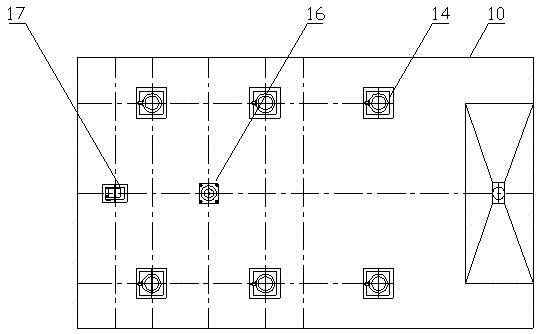

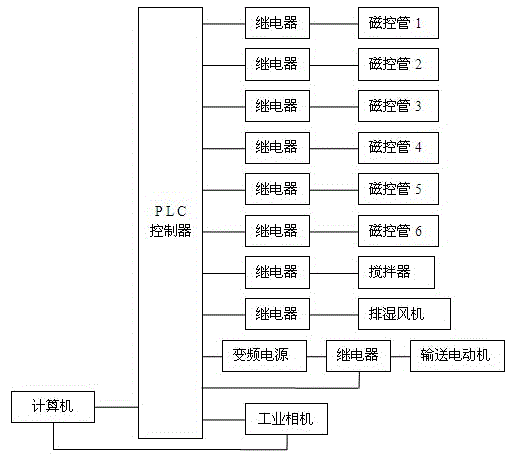

[0021] Such as figure 1 , figure 2 , image 3 As shown, the tunnel-type vegetable microwave dryer includes a conveying system, a heater, and an anti-no-load control system, and the heater is fixed above the conveying system;

[0022] The conveying system includes a driven roller 3, a lower hopper 4, a frame 5, a white conveyor belt 6, a support roller 7, a conveying motor 11, and a driving roller 13, and the driven roller 3 and the driving roller 13 are respectively fixed on the frame through bearing supports. 5 both ends, the driven roller 3, the driving roller 13 and the white conveyor belt 6 form a belt transmission system, a plurality of support rollers 7 are evenly fixed on the two longitudinal beams of the frame 5, below the white conveyor belt 6, and the conveyor motor 11 is fixed Install the lower part of one end of the driving drum 13 on the frame 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com