Modification method of wheat gluten protein and application of wheat gluten protein in yoghurt product

A technology of wheat gluten and dairy products, applied in the direction of milk preparations, applications, dairy products, etc., can solve the problems of insoluble water, unsatisfactory requirements, restrictions, etc., to achieve increased molecular flexibility, simple and orderly production process, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] According to the mass ratio, dissolve 5% wheat gluten peptide in water, put it into a single-mouth bottle, and configure it as a suspension. According to the mass ratio, 0.5% acetic acid was added to the suspension, and the one-mouth bottle was placed in a water bath shaker at room temperature, and hydrated for 8 hours. After the hydration time is up, stop shaking, move the single-necked bottle with evenly dispersed wheat gluten to a sterilizer that has been heated to 100°C, and set the temperature to 110-126°C for 10 minutes. After the deamidation of the organic acid, the gas is released quickly, taken out, cooled, dialyzed at 4°C for 24 hours, and then enzymatically hydrolyzed with alkaline protease. The optimal enzymatic hydrolysis temperature is 45°C, the substrate concentration is 5%, and 1% alkaline protease ([E] / [S]) is added for enzymolysis time to 12h. After the enzymolysis time is up, put the enzymolysis solution in a boiling water bath to inactivate the enzy...

Embodiment 2-3

[0028] Alkaline protease hydrolysis time were 24,36h. Other steps are with embodiment 1.

Embodiment 4-6

[0030] The deeply modified wheat gluten peptides with alkaline protease hydrolysis time of 36 hours were selected and added to the milk at the replacement amount of 3%, 5%, 10% (w / w) to replace the milk powder containing the same amount of protein. Other steps are with embodiment 1.

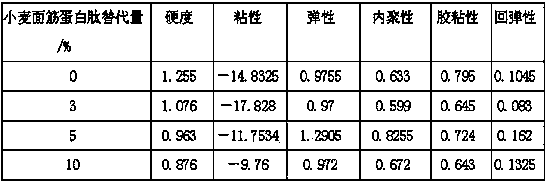

[0031] Table 1 The effect of wheat gluten peptide substitution on the texture of fermented yogurt

[0032]

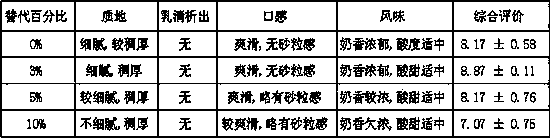

[0033] Table 2 Effect of wheat gluten peptide substitution on flavor and mouthfeel of fermented yogurt

[0034]

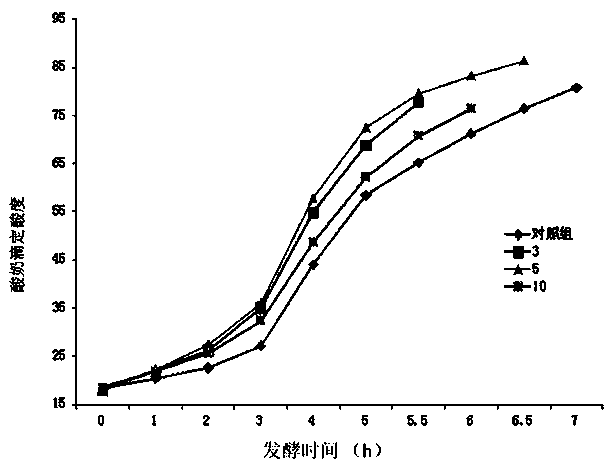

[0035] Depend on figure 1 , Table 1-2 shows that the modified wheat gluten peptide is applied to the yogurt system to replace a certain proportion of casein. When the replacement amount of modified wheat protein is 3%, the fermentation time of yogurt is shortened by about 1.5 h, and the texture is unchanged. The obvious change and good flavor of yogurt indicated that the modified wheat gluten peptide had good adaptability to the food application system of acidic system,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com