Scalding pool for pig slaughtering

A conveying rail and pulley technology, applied in the field of slaughtering, can solve the problems of unfavorable and flexible arrangement of slaughter lines, running line length, carcass decoupling, etc., and achieves the effects of not easy decoupling, reducing steam waste, and flexible arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

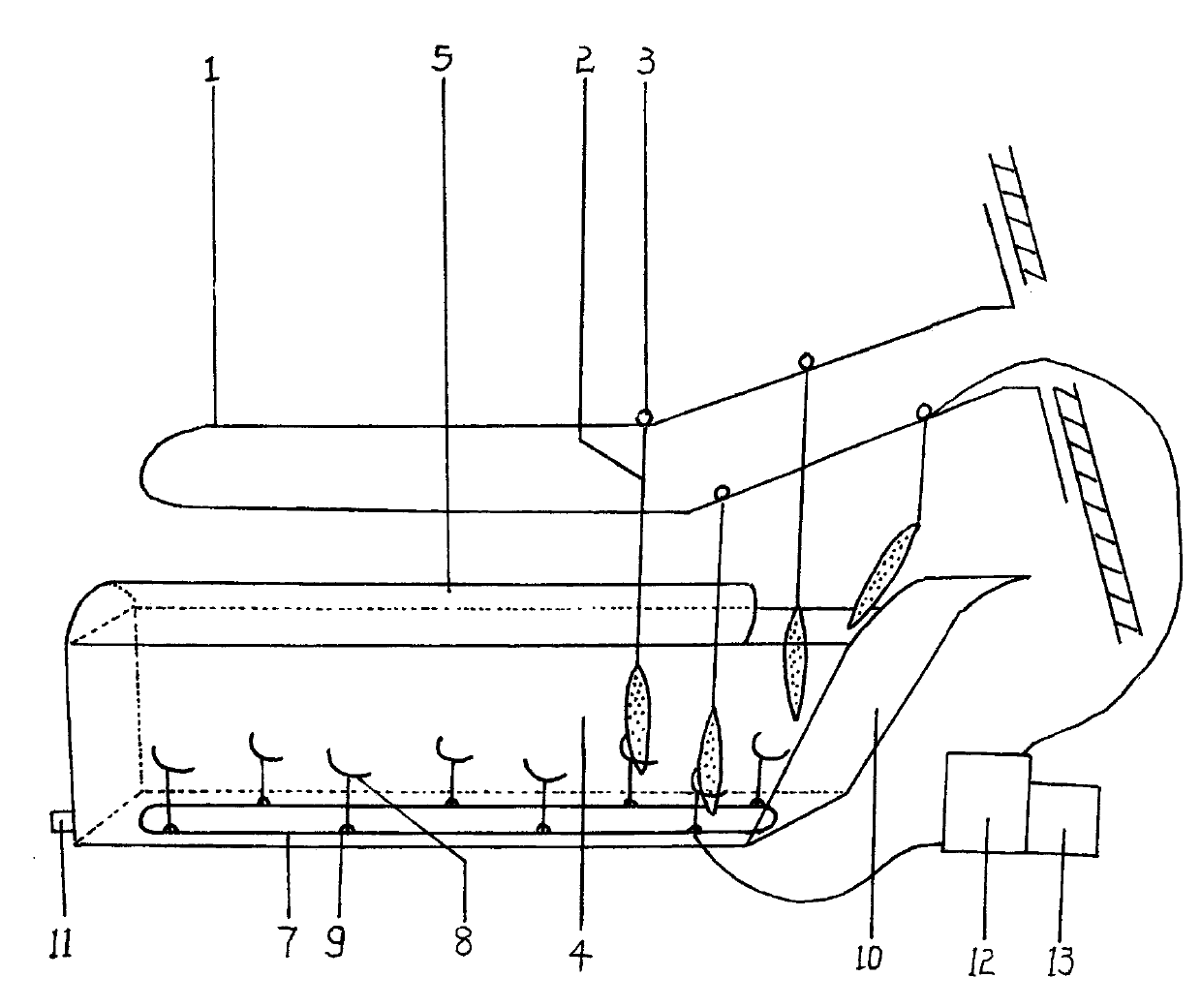

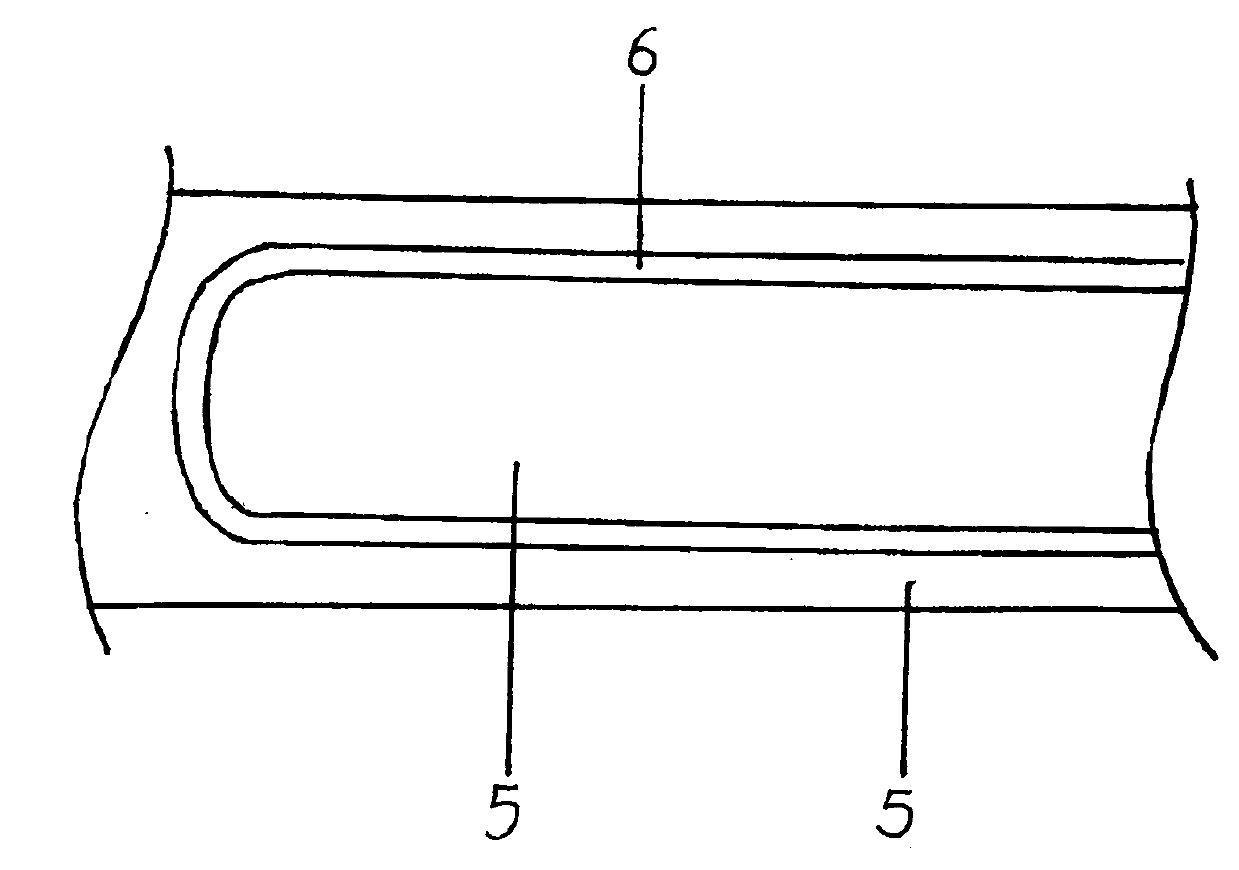

[0009] A scalding pool for slaughter pigs, comprising a conveyor rail 1, a hanging chain 2, an upper pulley 3, a scalding pool 4, a top cover 5, a hollow groove 6, an annular conveying rail 7, a limit frame 8, a lower wheel 9, and a slope surface 10. Drainage port 11, motor 12, reducer 13, there are several hanging chains 2 under the conveying rail 1, and the top of the hanging chain 2 is provided with an upper pulley 3 that can slide on the conveying rail 1. The top cover 5 of the scalding pool 4 is provided with a hollow groove 6 that matches the running track of the conveying rail 1. A slope surface 10 is provided on the side of the pig body entrance of the scalding pool 4 for the pigs on the lifting chain 2. The body slowly enters the ironing pool 4 to reduce the impact force on the water of the ironing pool 4 when it falls. The bottom of the ironing pool 4 is provided with a drainage port 11 and an annular conveying rail 7. There are several limit racks 8 on the annular con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com