Equipment for scanning facial porosity of rock and method thereof

A technology of surface porosity and equipment, which is applied in the field of oil drilling, can solve the problems of large measurement error of rock surface porosity and failure to obtain rocks, etc., and achieve the effect of simple operation and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

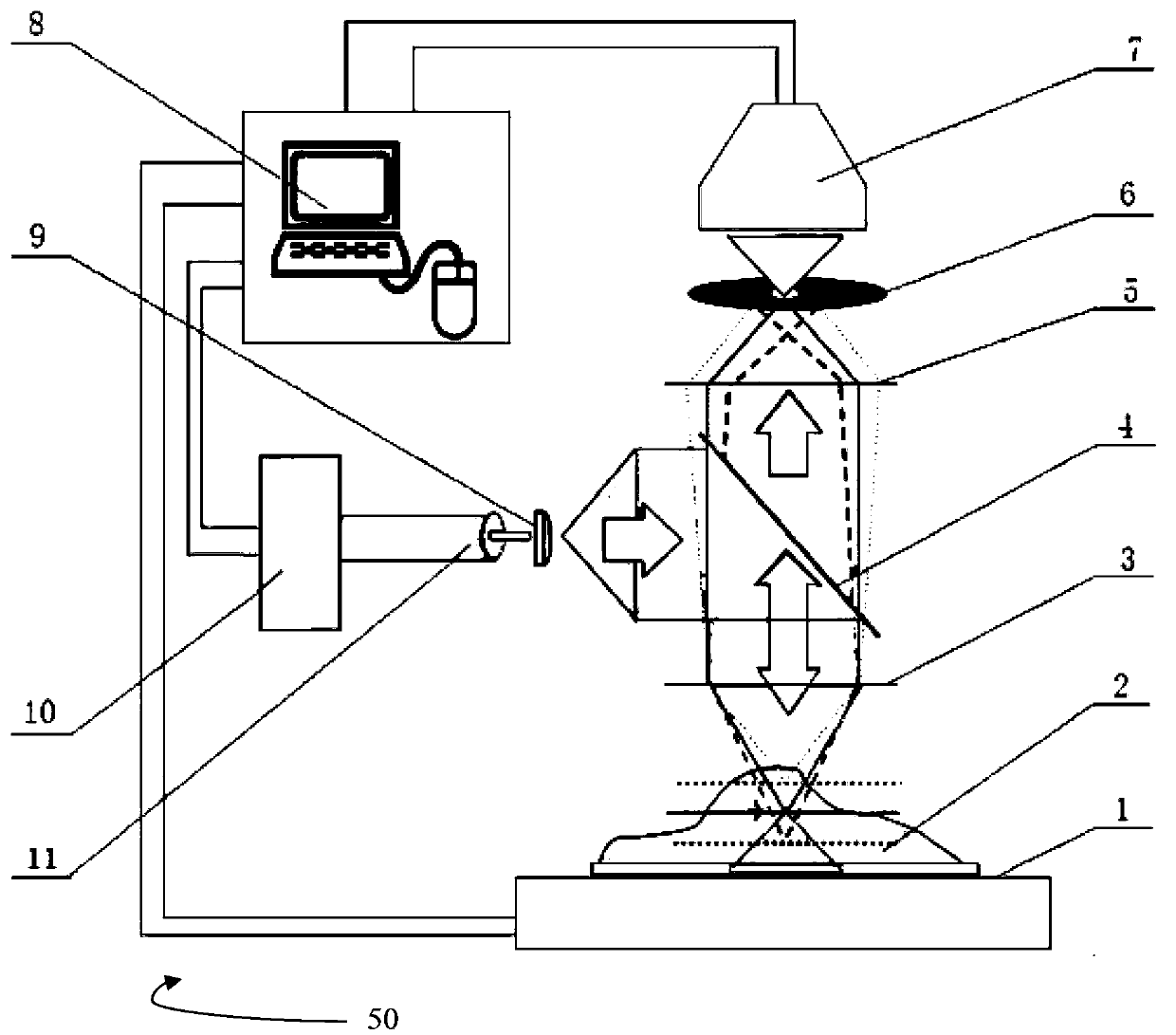

[0024] figure 1 A device 50 for scanning rock face porosity according to the invention is schematically shown.

[0025] The device 50 includes a stage 1 for placing a rock sample 2, and the stage 1 can move up and down slightly in the vertical direction. This can be achieved by providing a micro-motion mechanism for the stage 1 .

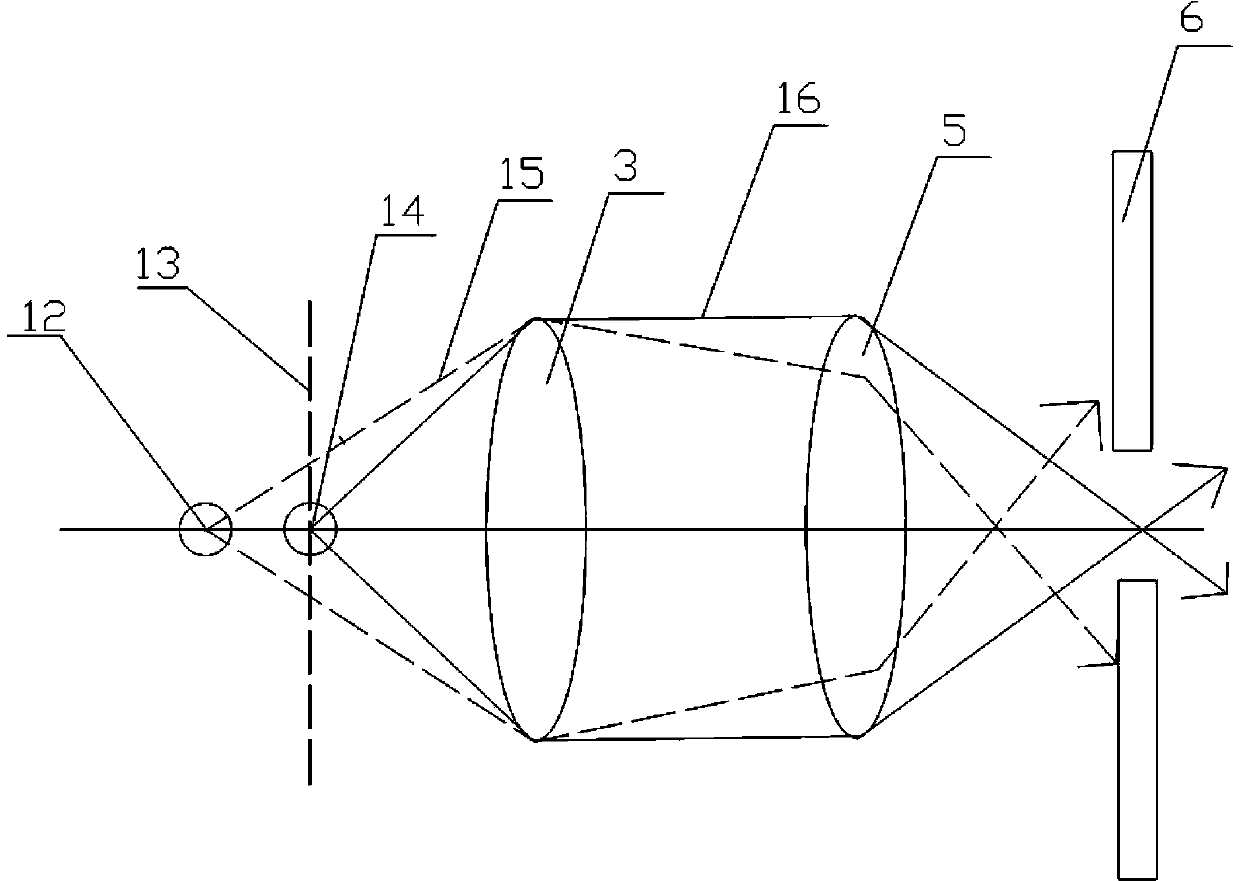

[0026] refer to figure 1 , an objective lens 3 , a polarizer 4 and a focusing lens 5 are arranged above the stage 1 from bottom to top. For observation, the focal point of the objective lens 3 is inside the rock sample 2, and the focal plane of the objective lens 3 is the section to be observed.

[0027] The fluorescence incident hole plate 6 is installed above the focusing lens 5 at a certain distance. The focal point of the focusing lens 5 is located in the light transmission hole of the fluorescence incident hole plate 6 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com