A uniform hydraulic pressure simulation loading device and method for tunnel structure model test

A tunnel structure and model test technology, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., can solve the problems of steel strand stress loss, cumbersome operation, and inability to apply uniform water pressure, etc., to achieve uniform stress loading, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

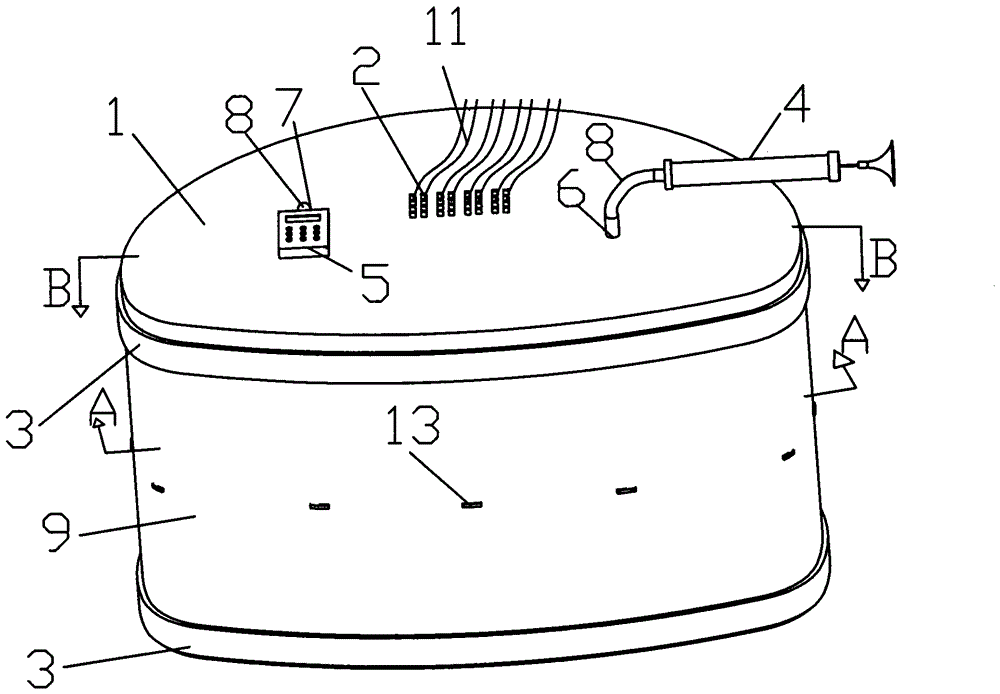

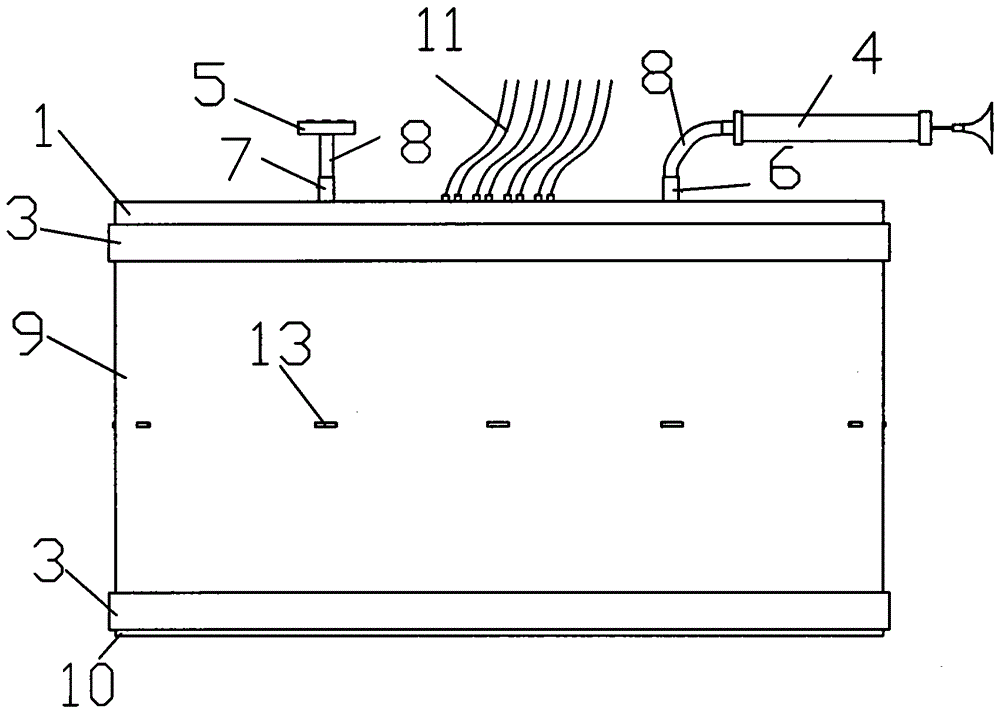

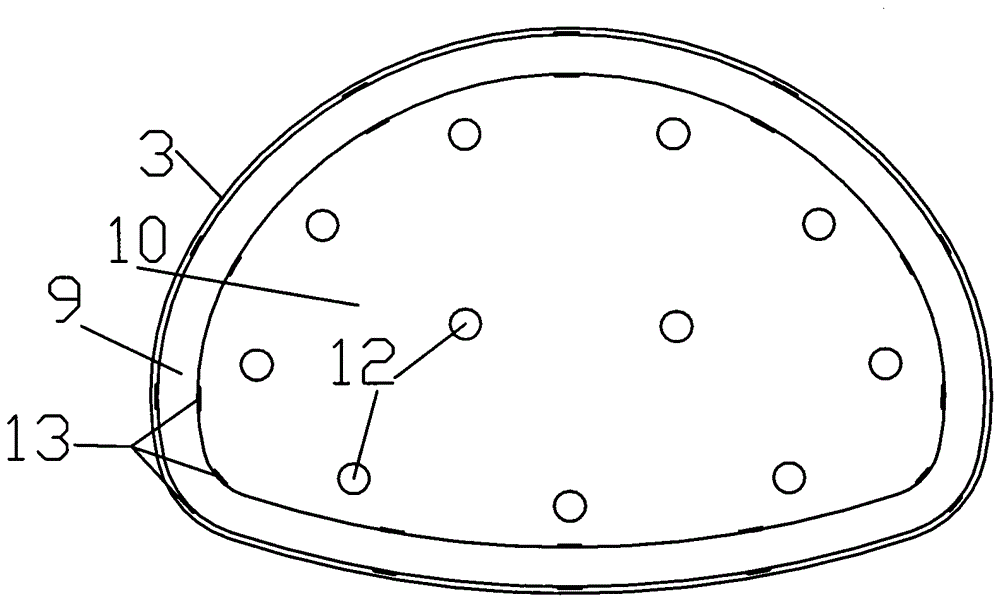

[0037] The following will take a tunnel with a non-circular cross-section as an example to introduce the present invention in detail. For other types of cross-sections, only a slight modification of the cross-section of the device is required. Figure 1-4As shown, a specific embodiment of the present invention is: a uniform hydraulic pressure simulation loading device for tunnel structure model test, which includes: top plate 1, bottom plate 10, column 12, flexible sealing strip 3, air extraction device 4 , high-precision absolute barometer 5, tunnel structure model 9, resistance strain gauge 13, in the inner and outer surfaces of the tunnel structure model 9, the resistance strain gauge 13 is pasted symmetrically and circumferentially, and the wire 11 of the inner surface resistance strain gauge 13 is welded , the wires of the outer surface resistance strain gauges are directly led out, and grouped with the inner surface wires and welded on the strain box for reading data.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com