A Calibration Method of Thermal Resistance Heat Flow Sensor

A heat flow sensor and calibration method technology, which is applied to calorimeters, instruments, scientific instruments, etc., can solve the problems of high error and difficult calibration work, achieve accurate calibration results, high precision, and improve experimental efficiency and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

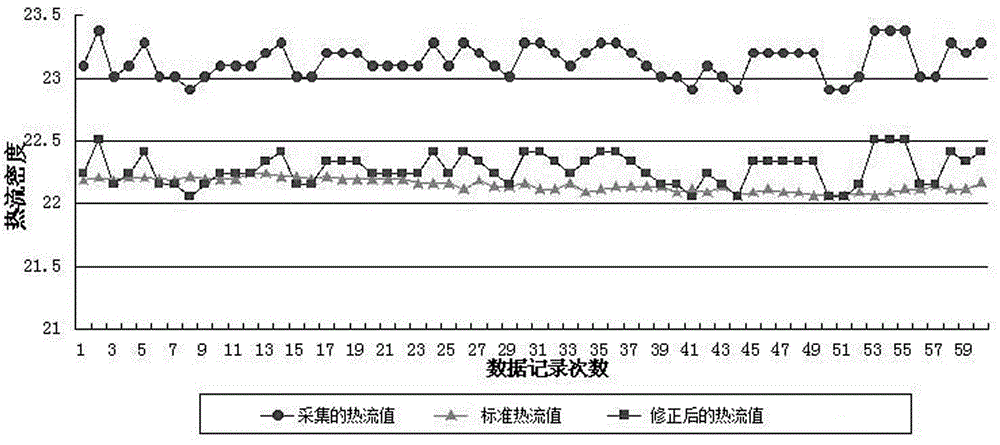

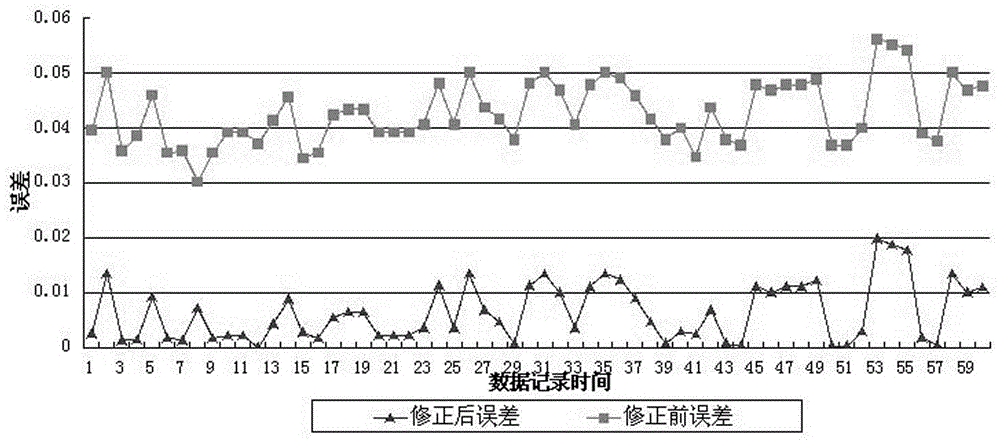

[0023] Attached below figure 1 , attached figure 2 The present invention will be further described.

[0024] The calibration method of the thermal resistance type heat flow sensor comprises the following steps

[0025] (1) A heat conduction plate is installed between the cold box and the hot box, and the cold box and the hot box are respectively provided with a flow guide screen to form a convection on the surface of the heat conduction plate. The finned heat exchanger in the cold box is connected to the chiller, and the hot box An electric heater is provided. (2) A number of heat flow sensors and a number of temperature sensors are symmetrically installed on both sides of the heat conduction plate, and each heat flow sensor and temperature sensor is numbered and connected to the heat flow-temperature inspection instrument. (3) After working in the cold box and hot box for 4-8 hours, the heat flow value collected by each heat flow sensor And the temperature of the cold s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com