An installation method of a sintering machine dust removal system

A technology of dust removal system and installation method, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc., which can solve the problems of difficult installation quality assurance, long installation time, and many installation hidden dangers, and achieve easy lifting and counterpart connection, and work The effect of reducing the amount and reducing the labor operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

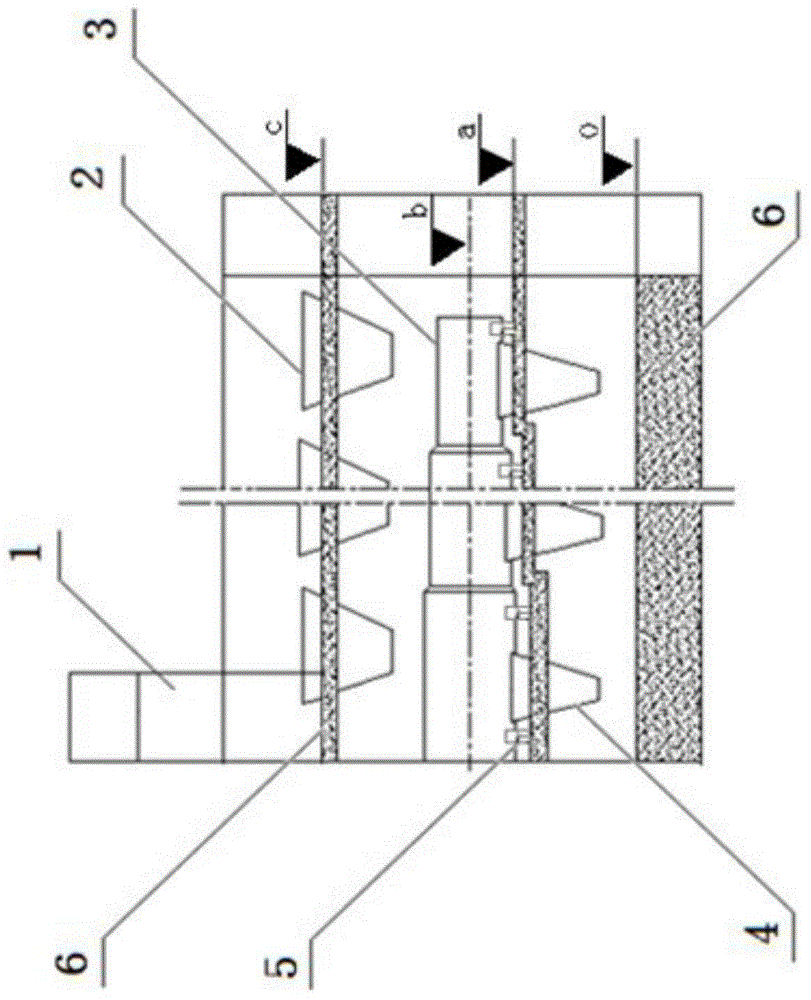

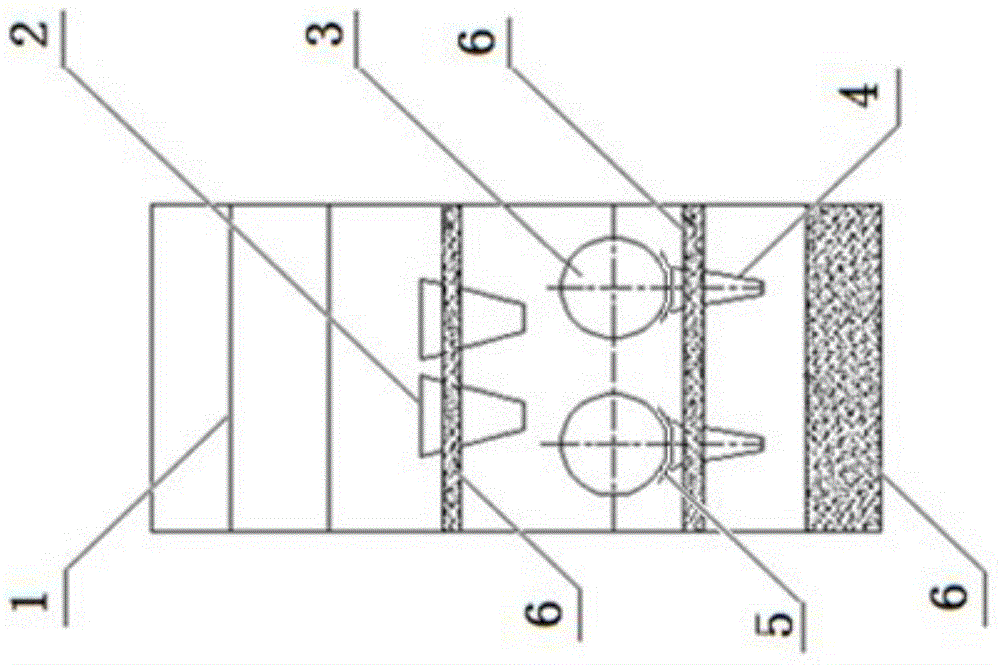

[0056] In order to make the technical solution of the present invention more clearly understood, it will be described in detail below in conjunction with the accompanying drawings and embodiments.

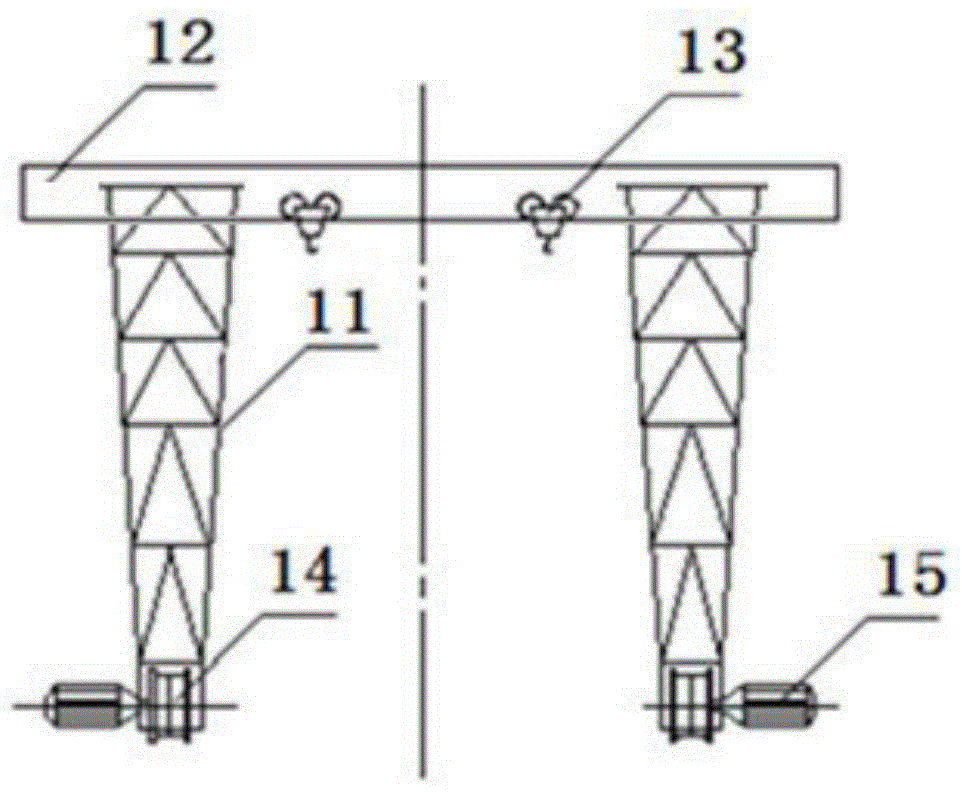

[0057] The installation method of the dust removal system of the sintering machine of the present invention is carried out by adopting a self-made gantry type electric suspension vehicle and a bracket type electric vehicle.

[0058] refer to image 3 , Figure 4 , the gantry type electric suspension vehicle includes two vehicle frames 11 made of angle steel, H-shaped steel or steel plate; the upper ends of the two vehicle frames 11 are provided with vehicle beams 12, and the vehicle beams 12 are laid The steel plates on both sides of the width of the upper end of the vehicle frame 11 are composed of steel plates welded between the two steel plates. The slideway and the two cat head cranes 13 installed thereon constitute a sliding movement pair; two sides of the bottom end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com