Dry distillation smokeless dust removal garbage incinerator

A waste incinerator and dry distillation technology, which is applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of high cost of use and inability to achieve the effect, and achieve the effect of easy maintenance, reducing the probability of smoke and dust, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

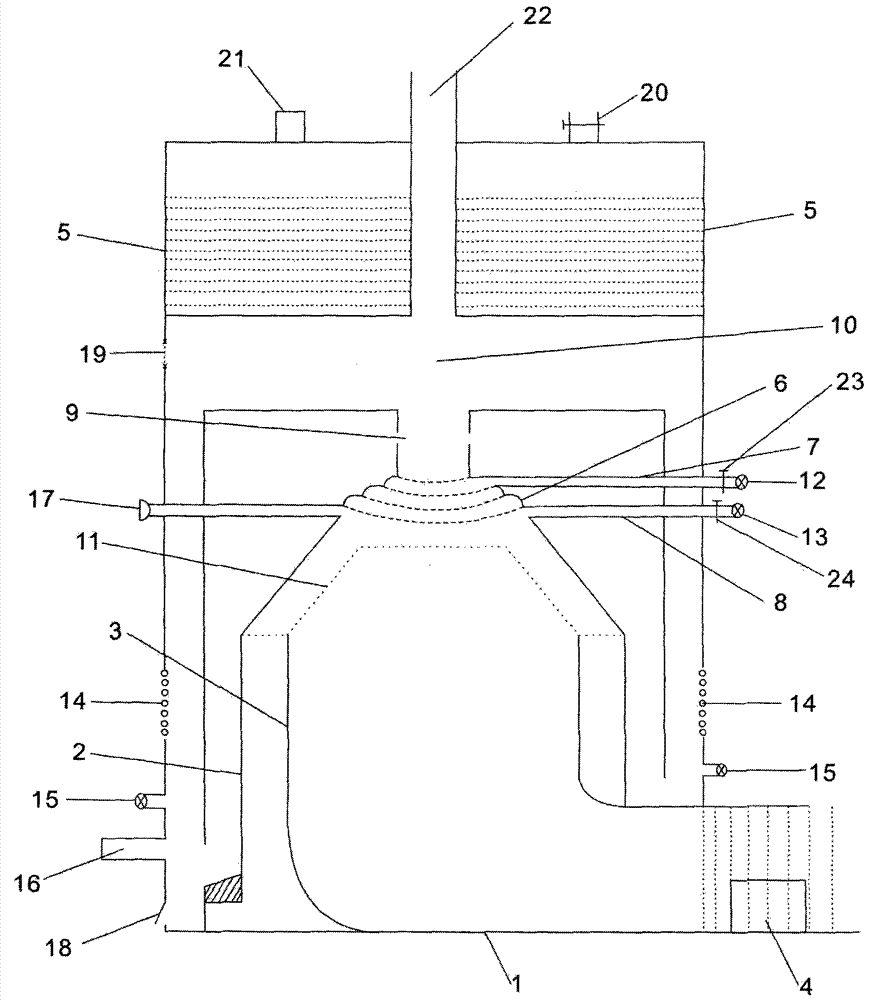

[0027] A dry distillation smokeless dust removal garbage incinerator, comprising a furnace body 1, a bottle-shaped furnace 2 is arranged in the furnace body 1, an upper oxygen supply pipeline 7 and a lower oxygen supply pipeline 8 are arranged at the upper bottleneck of the furnace 2, two oxygen supply pipelines One end of the pipeline is connected with the furnace 2, and the other end is connected with the first oxygen supply machine 12 and the second oxygen supply machine 13 outside the furnace body 1, wherein the first oxygen supply machine 12 and the second oxygen supply machine 13 are fans, and The upper oxygen supply pipeline 7 and the lower oxygen supply pipeline 8 are provided with a first wind control switch 23 and a second wind control switch 24 respectively, and several downward extending valves are arranged on the relative horizontal point of the oxygen supply port in the bottle neck of the upper oxygen supply pipeline 7 . The arc-shaped oxygen supply tank 6 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com