Motor-driven type throttle servo system

A technology of servo system and motor drive, which is applied in the direction of machines/engines, electrical control, mechanical equipment, etc., and can solve problems such as the transformation of electronic control units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

[0041] In order to better understand the present invention, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

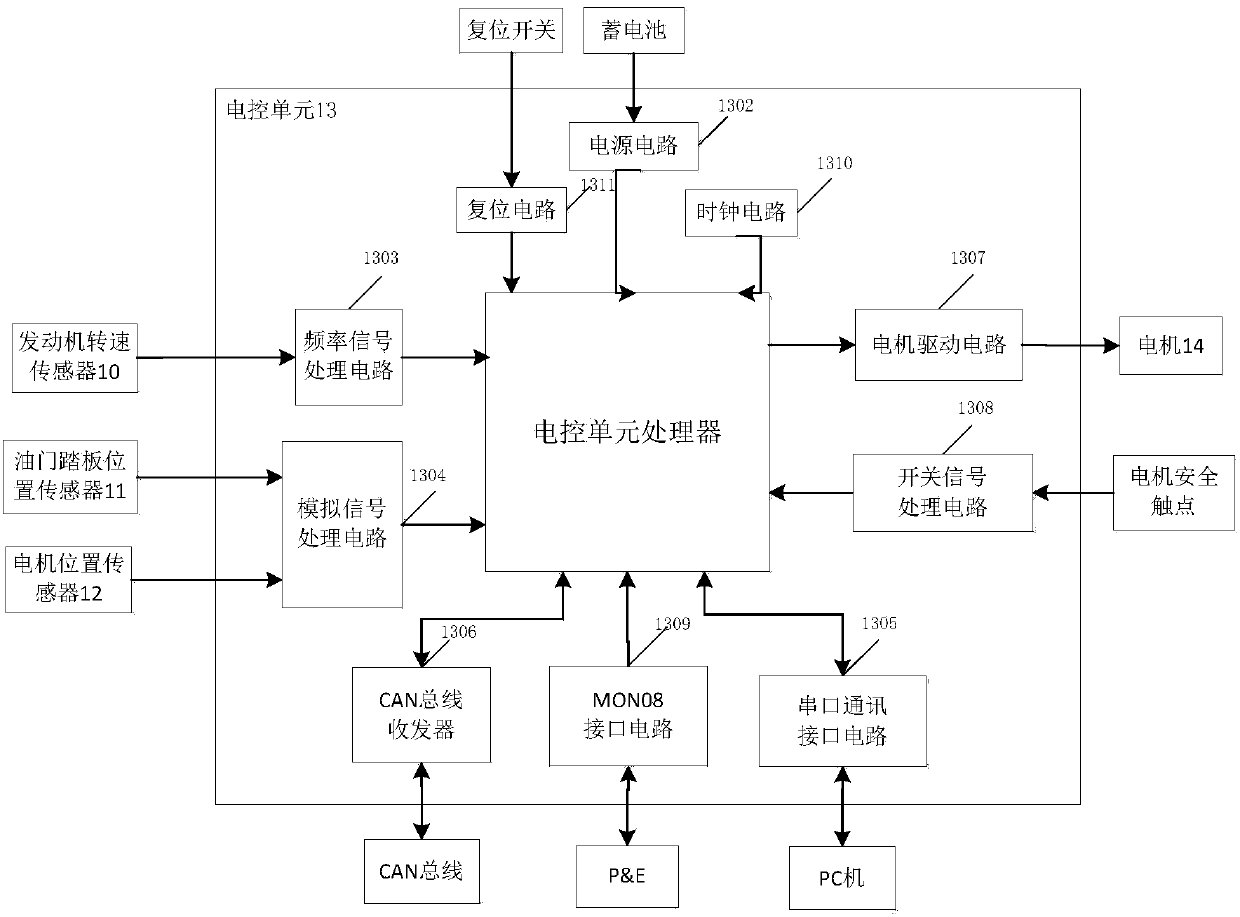

[0042] like figure 1 as shown, figure 1 It is a schematic structural diagram of the accelerator servo system according to the embodiment of the present invention, which may specifically include:

[0043] The engine speed sensor 10 is used to sense the engine speed and output the engine speed signal;

[0044] The accelerator pedal position sensor 11 is used to sense the accelerator pedal position and send the accelerator pedal position signal;

[0045] The motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com