Brown coal drying power generating system capable of recycling water in coal and implementation method of brown coal drying power generating system

A technology of power generation system and implementation method, which is applied in the direction of combustion method, drying, drying machine, etc., can solve the problems of enlarged boiler body, energy waste, and high cost, so as to reduce the dry coal transportation process and reduce the cold end Effects of reducing heat loss and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following description is only for demonstration and explanation, and does not limit the present invention in any form.

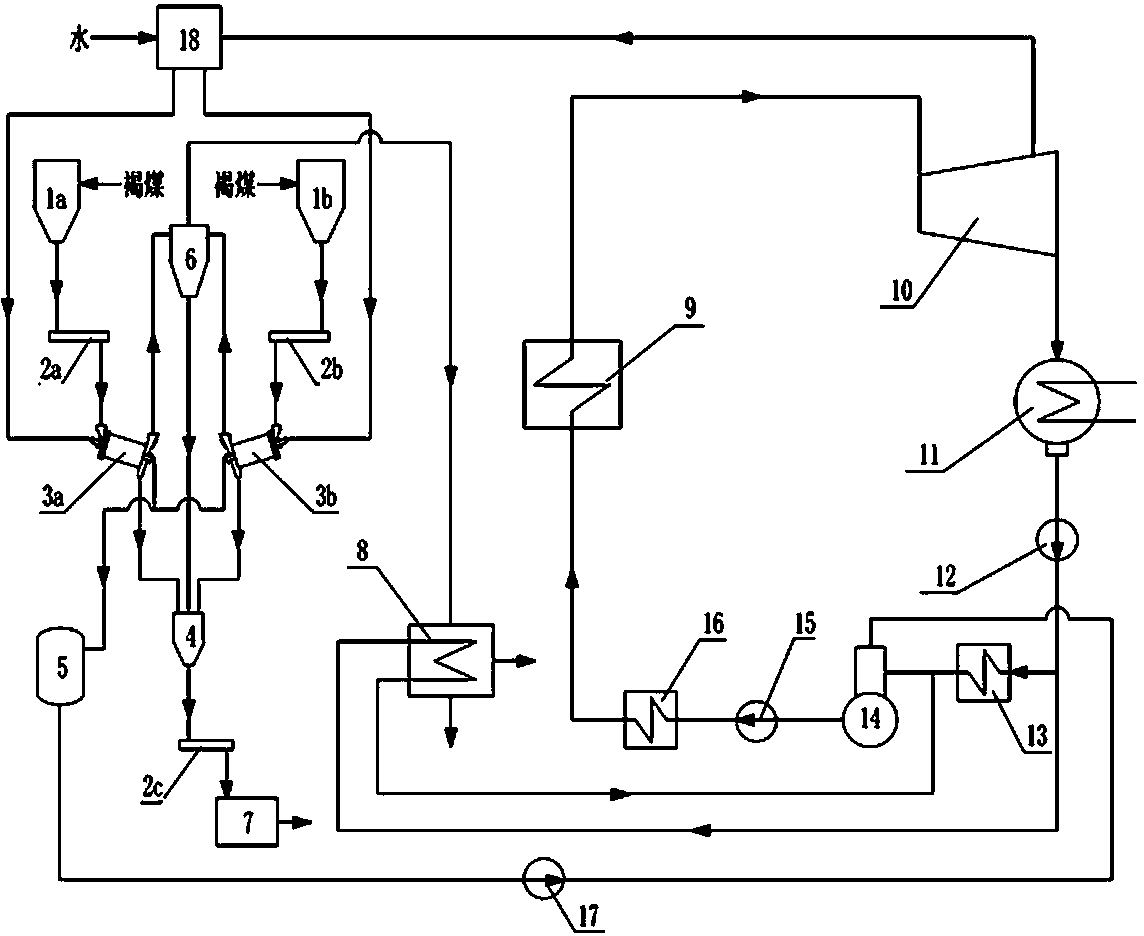

[0045] Such as figure 1 As shown, boiler 9 and steam turbine 10, low-pressure feed water pump 12, high-pressure feed water pump 15, condenser 11, coal mill 7, lignite drying device, coal water recovery device 8, raw coal bunker, low-pressure heater 13, oxygen removal Device 14, high-pressure heater 16, condensate pump 17, steam-water mixer 18 constitute lignite drying power generation system, and its lignite drying device includes dryer, coal feeder, dry coal bin 4, condensation tank 5, dust collector 6, through The lignite drying device, coal water recovery device and boiler overall layout design, coal water recovery device and steam turbine heat recovery system are combined to realize the operation of large-capacity lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com