Preparation method of troxerutin

A technology of trishydroxyethylrutin and monohydroxyethylrutin is applied in the field of preparation of trishydroxyethylrutin, can solve the problems of difficult removal, no product supply, undisclosed preparation method, etc., and achieves low cost, Production cost saving, good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

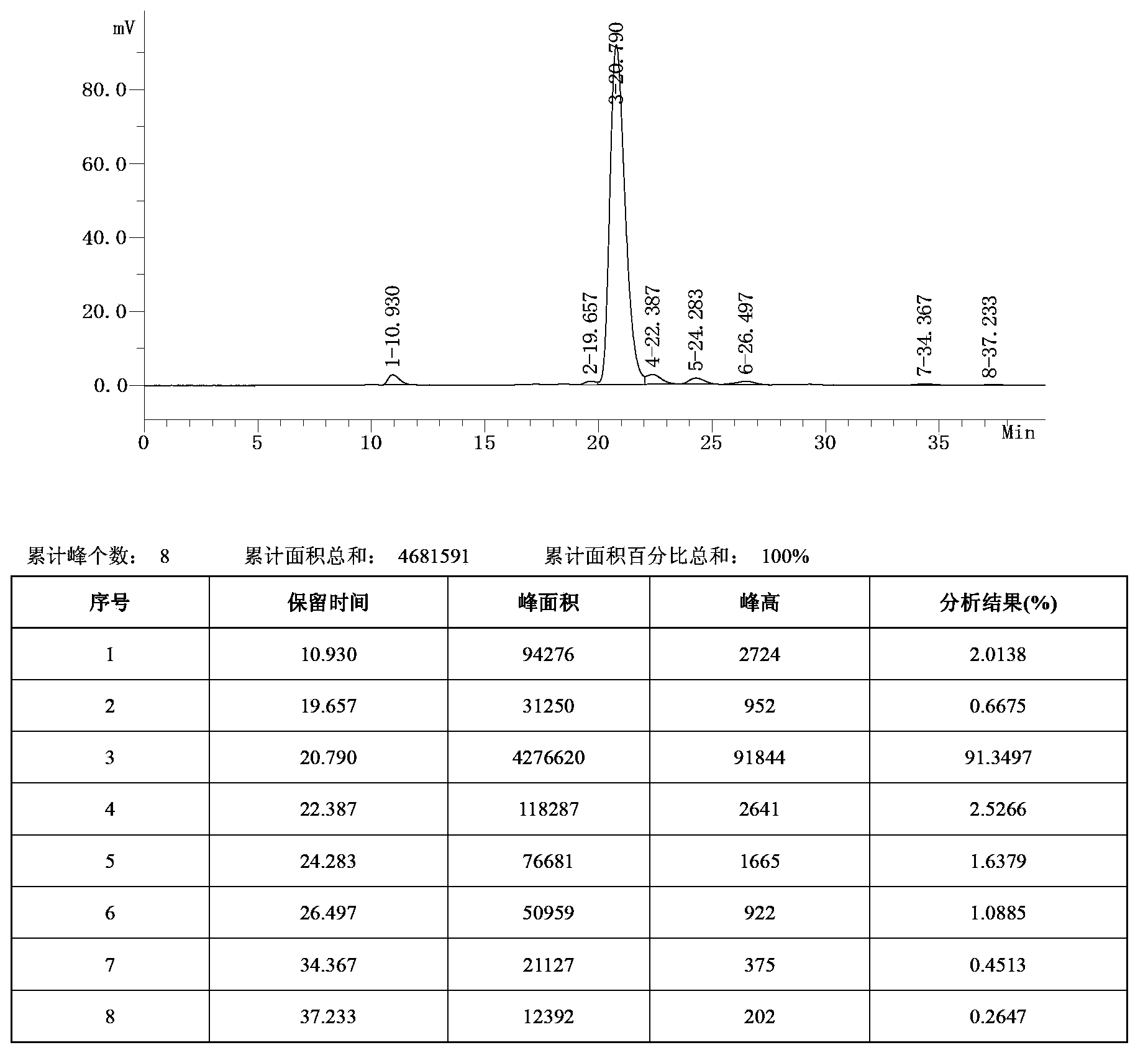

Embodiment 1

[0065] 1. 328 grams, 0.86 moles of borax (Na 2 B 4 o 7 10H 2 O) Add 2500ml of deionized water, stir to dissolve, then add 605 grams, 0.82 moles of rutin, stir at 40-45°C until dissolved, filter to obtain a clear aqueous solution of rutin-borax complex. The solution was kept at 40-45°C. Under the stirring state, 88 grams, 2 moles of ethylene oxide were gradually passed into the reaction solution. The reaction time was about 6 hours. The reaction was detected by HPLC until it was completely reacted. The pH of the reaction solution was adjusted to 2.0 with 5N hydrochloric acid. , placed at 3-5°C for 12 hours, and suction filtered to obtain a solid filter cake containing 504 grams of 7-monohydroxyethyl rutin, with a yield of 95%.

[0066] 2. Take 1,460 grams of 7-monohydroxyethyl rutin aqueous solid obtained in 1, add 4,750 ml of deionized water, heat to 60°C under stirring, dissolve it completely, filter, place the filtrate at 3-5°C overnight, and suction filter to obtain the ...

Embodiment 2

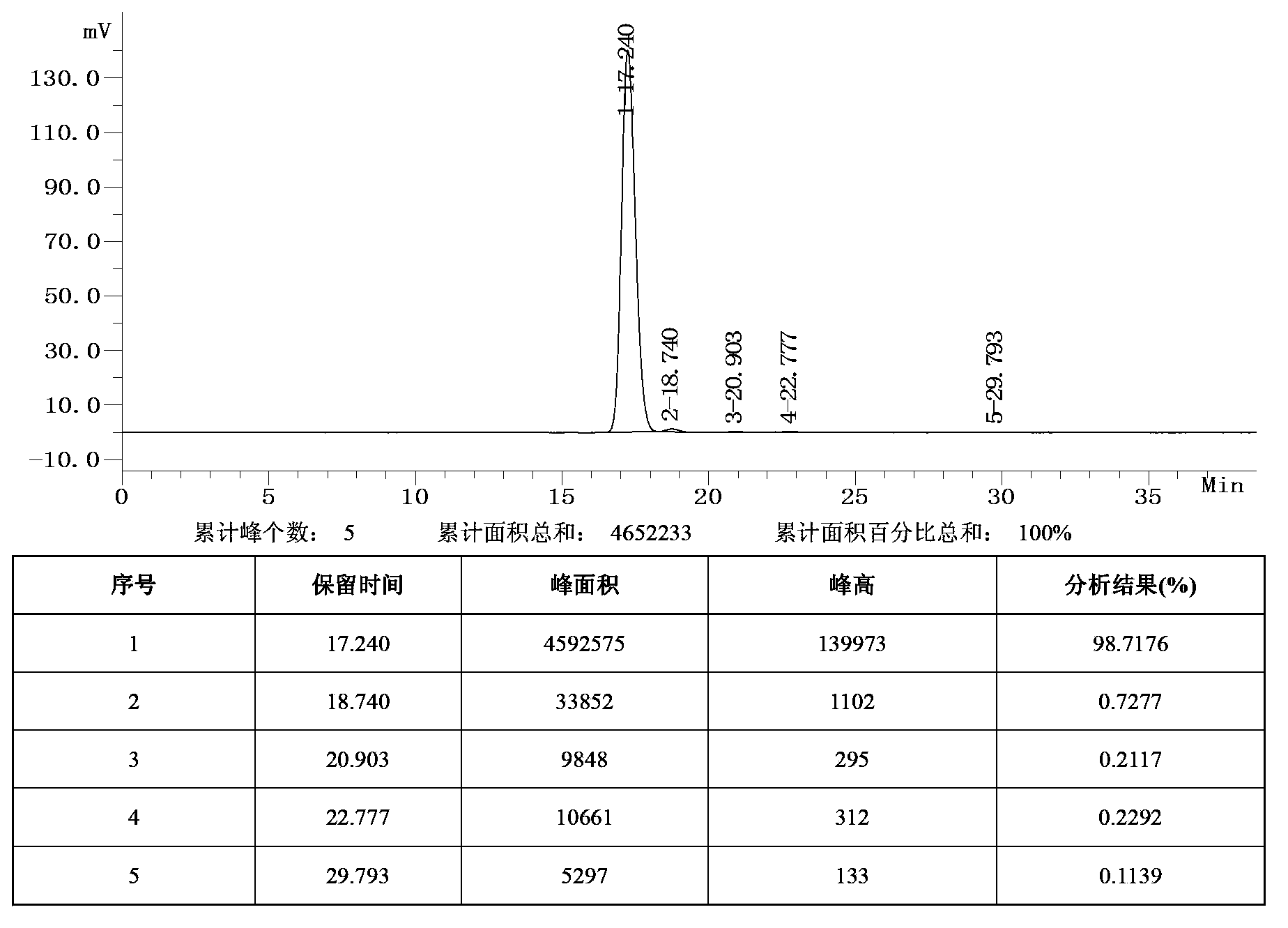

[0071] 1. 164 grams, 0.43 moles of borax (Na 2 B 4 o 7 10H 2 O); 12 grams, 0.3 moles of sodium hydroxide (NaOH) was added to 2000ml of deionized water, stirred and dissolved, then added 605 grams, 0.82 moles of rutin, heated to and kept at 40-45 ° C, under stirring, the 88 Gradually, 2 moles of ethylene oxide were introduced into the reaction solution step by step. The reaction time was about 12 hours. The reaction was detected by HPLC until it was completely reacted. A solid filter cake was obtained, containing 510 grams of 7-monohydroxyethyl rutin, with a yield of 96%. .

[0072] 2. Take 510 grams of 7-monohydroxyethyl rutin obtained in 1 (total weight 1450, water content 940 grams), add 2000 ml of deionized water, heat to 40 °C under stirring, add a saturated aqueous solution of sodium bicarbonate dropwise until the solids are completely Dissolve, filter, and adjust the pH of the filtrate to 4.0 with 0.1 mole hydrochloric acid, place it overnight at 3-5°C, filter with ...

Embodiment 3

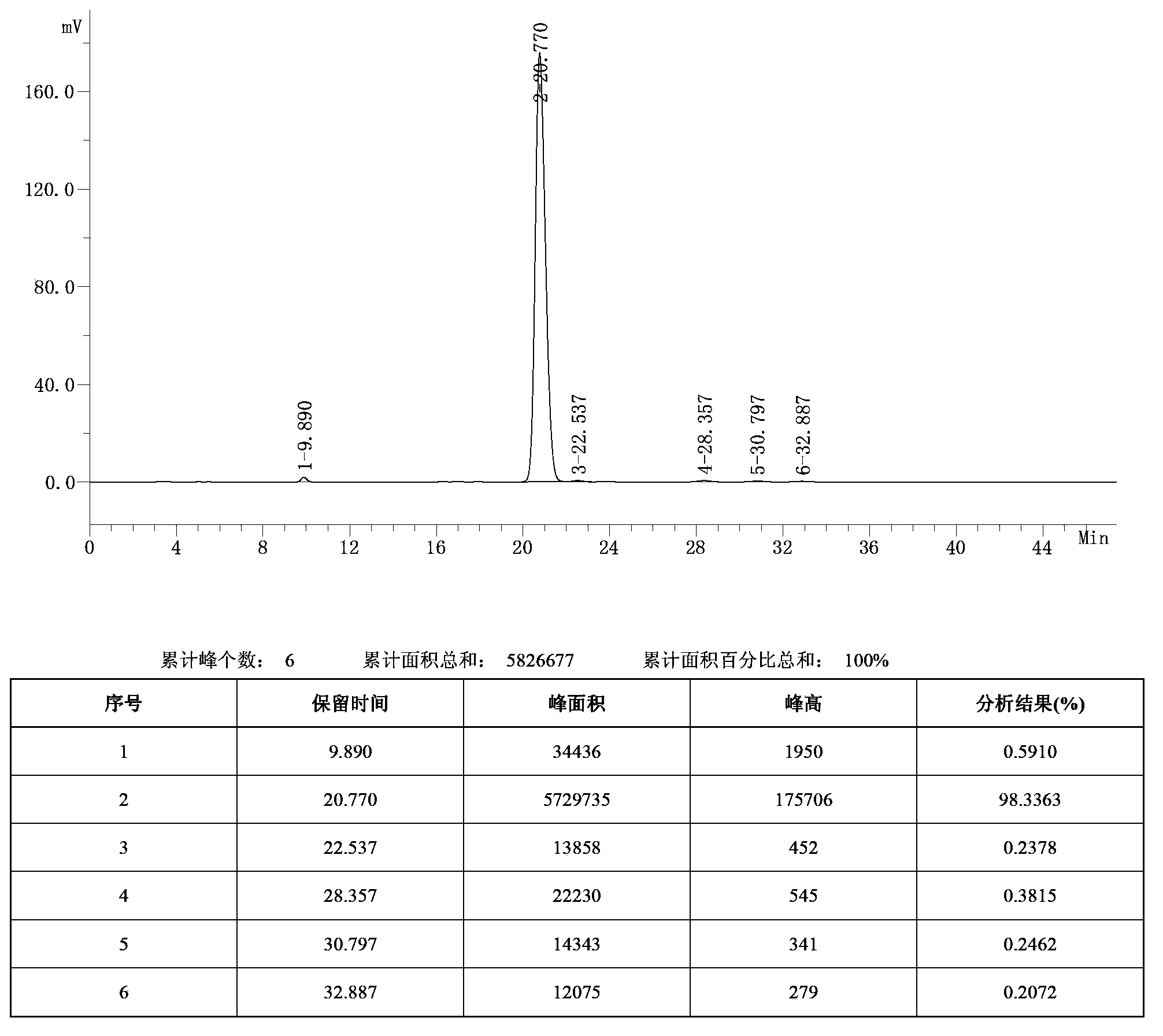

[0077] 1. 328 grams, 0.86 moles of borax (Na 2 B 4 o 7 10H 2 O) Add 2000ml of deionized water, stir to dissolve, then add 605g, 0.82 mole of rutin, stir at 40-45°C until dissolved, filter to obtain a clear aqueous solution of rutin-borax complex. The solution is kept at 40-45°C. Under the stirring state, 88 grams, 2 moles of ethylene oxide are gradually passed into the reaction solution. The reaction time is about 6 hours. The reaction is completely detected by HPLC. The reaction solution is directly pretreated by conventional methods. Good D101 macroporous resin for separation and purification, the amount of resin used is 25 kg, after the sample is loaded, rinse with deionized water until the pH of the effluent is near neutral, first rinse with 2000ml of 10% ethanol, then rinse with 10000ml of 60% ethanol, and then rinse with Rinse completely with 90% ethanol, collect the effluent of 60% ethanol, concentrate in vacuum until there is no alcohol smell, add water to 12000ml, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com