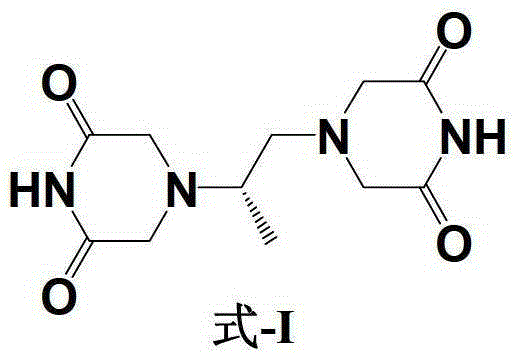

A kind of preparation method of dextropropanimine

A technology of dextropropyl imine and formamide, which is applied in the field of preparation of dextropropyl imine, can solve the problems of high cost, harsh reaction conditions, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

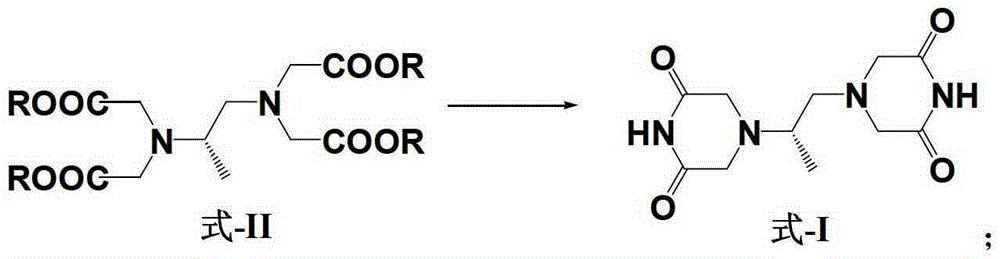

Method used

Image

Examples

Embodiment 1

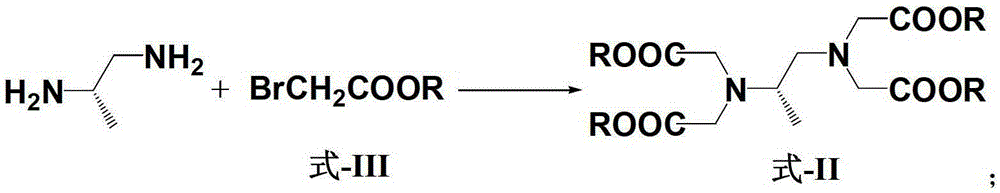

[0078] Embodiment 1: the preparation of (S)-1,2-diaminopropane-tetraacetic acid methyl ester:

Embodiment approach 11

[0080] (S)-1,2-diaminopropane hydrochloride (500mg, 3.4mmol, 1eq), methyl bromoacetate (5202mg, 34mmol, 10eq), potassium carbonate (4692mg, 34mmol, 10eq), acetonitrile (34mL, 0.1M) were added to 100mL single-necked bottles, and reacted at 25°C for 24 hours. After the reaction was completed, the inorganic salts were filtered off, the filtrate was concentrated to dryness, and HCl (15mL, 12%) solution was added to acidify, and petroleum ether (15ml×2, 60~90℃), adjusted the pH to 10 with saturated sodium carbonate solution, extracted with dichloromethane (15ml×3), dried and concentrated to dryness to obtain the crude product (S)-1,2-diaminopropane-tetra Methyl acetate, crude product yield 55%.

Embodiment approach 12

[0082] (S)-1,2-diaminopropane hydrochloride (500mg, 3.4mmol, 1eq), methyl bromoacetate (5202mg, 34mmol, 10eq), potassium carbonate (4692mg, 34mmol, 10eq), acetonitrile (34mL, 0.1M) were added to 100mL single-necked bottles, and reacted at 25°C for 48 hours. After the reaction was completed, the inorganic salts were filtered off, the filtrate was concentrated to dryness, acidified by adding HCl (15mL, 12%) solution, and petroleum ether (15ml×2, 60~90℃), adjusted the pH to 10 with saturated sodium carbonate solution, extracted with dichloromethane (15ml×3), dried and concentrated to dryness to obtain the crude product (S)-1,2-diaminopropane-tetra Methyl acetate, crude product yield 68%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com