Method for preparing radiation-resistant concrete from lead-containing CRT (cathode ray tube) glass

A concrete and radiation protection technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as pollution of the environment, achieve the promotion of absorption, be beneficial to resource recycling and environmental protection, and satisfy the ray absorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

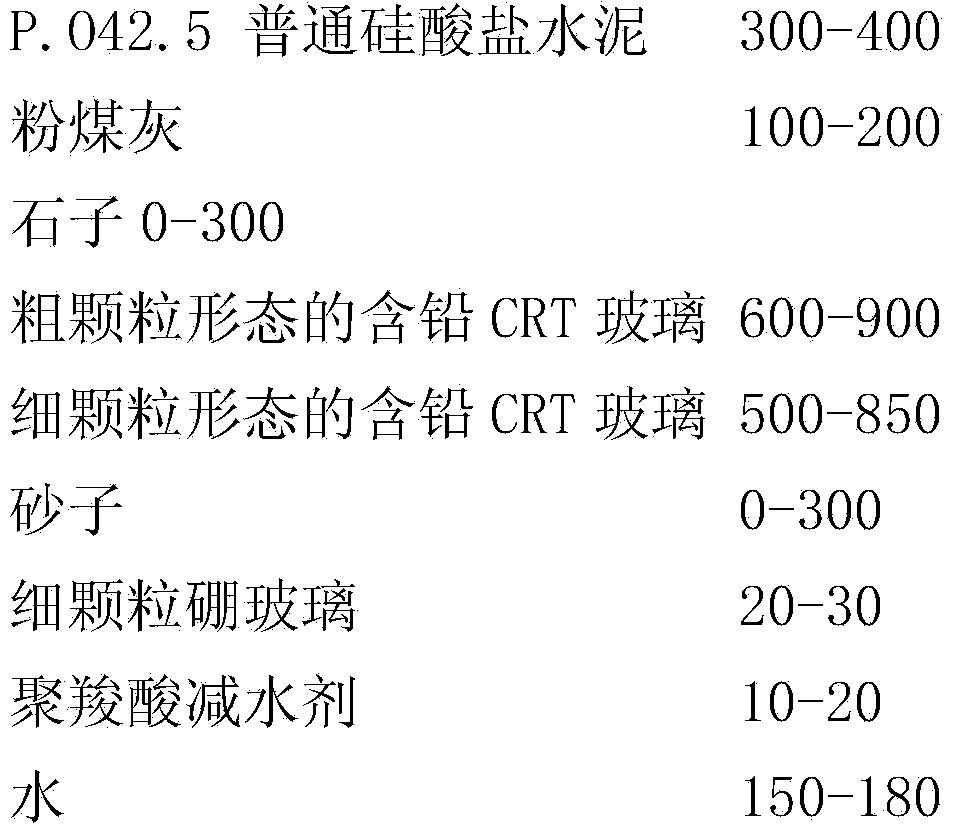

[0035] A method for preparing radiation-proof concrete from leaded CRT glass, firstly, clean leaded CRT glass is broken, including cone glass, neck tube glass and low melting point sealing glass, and the lead oxide mass content average value of leaded CRT glass can be Up to 23.5%, 6-30mm is used as coarse aggregate, 6mm or less is used as fine aggregate, the size of stones is controlled at 10-30mm, and the size of sand is less than 1.5mm.

[0036] Ratio of anti-radiation concrete prepared with leaded CRT glass (unit: kg): P.O 42.5 ordinary portland cement 300, fly ash 200, coarse particle leaded CRT glass 900, fine particle leaded CRT glass 850, fine particle boron glass 20, polycarboxylate superplasticizer 20, water 150. Wherein the chemical composition of boron-containing glass is (wt%): SiO 2 50, Al 2 o 3 16,B 2 o 3 25,Li 2 O 1,Na 2 O 1,K 2 O 3, CaO 1, MgO 1, BaO 2, SrO 1, ZnO 1.

[0037] Preparation process: weigh stones, leaded CRT glass in particle form, leaded ...

Embodiment 2

[0039] A method for preparing radiation-proof concrete from leaded CRT glass, firstly, clean leaded CRT glass is broken, including cone glass, neck tube glass and low melting point sealing glass, and the lead oxide mass content average value of leaded CRT glass can be Up to 23.8%, 6-30mm is used as coarse aggregate, 6mm or less is used as fine aggregate, the size of stone is controlled at 10-30mm, and the size of sand is less than 1.5mm.

[0040] Ratio of anti-radiation concrete prepared with leaded CRT glass (unit: kg): P.O 42.5 ordinary Portland cement 330, fly ash 170, gravel 100, coarse grained leaded CRT glass 800, sand 100, fine grained grained leaded CRT glass 700, fine particle boron glass 23, polycarboxylate superplasticizer 17, water 160. Wherein the chemical composition of boron-containing glass is (wt%): SiO 2 64, Al 2 o 3 6,B 2 o 3 9, Li 2 O 3 , Na 2 O 12,K 2 O 3, CaO 0.3, MgO 0.4, BaO 1, SrO 0.7, ZnO 0.6.

[0041] Preparation process: weigh stones, leade...

Embodiment 3

[0043] A method for preparing radiation-proof concrete from leaded CRT glass, firstly, clean leaded CRT glass is broken, including cone glass, neck tube glass and low melting point sealing glass, and the lead oxide mass content average value of leaded CRT glass can be Up to 23.5%, 6-30mm is used as coarse aggregate, 6mm or less is used as fine aggregate, the size of stones is controlled at 10-30mm, and the size of sand is less than 1.5mm.

[0044] Ratio of anti-radiation concrete prepared by leaded CRT glass (unit: kg): P.O 42.5 ordinary portland cement 400, fly ash 100, stone 200, coarse grained leaded CRT glass 700, sand 200, fine grained leaded CRT glass 600, fine particle boron glass 26, polycarboxylate superplasticizer 13, water 170. Wherein the chemical composition of boron-containing glass is (wt%): SiO 2 70,Al 2 o 3 5,B 2 o 3 6, Li 2 O2, Na 2 O 3,K 2 O2, CaO2, MgO1, BaO6, SrO2, ZnO1.

[0045]Preparation process: weigh stones, leaded CRT glass in the form of pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com