Polycarboxylic acid water retention agent, and preparation method and application thereof

A technology of water-retaining agent and polycarboxylic acid, which is applied in the field of concrete admixtures, can solve the problems of unsatisfactory use of raw materials and poor cement effect, etc., and achieve the effects of improving volume stability and durability, small shrinkage of concrete, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

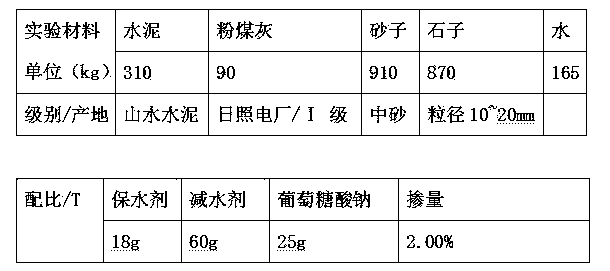

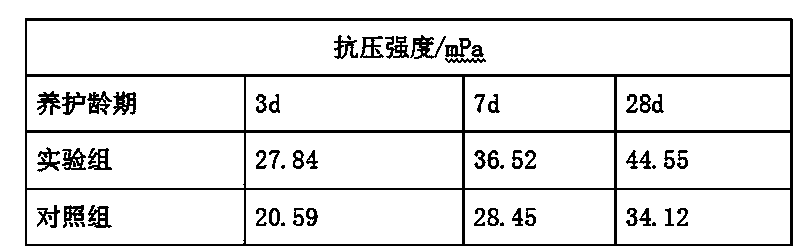

Examples

Embodiment 1

[0028] Step 1: Weigh 360kg of polyether macromonomer, put it into a mixing tank, add water until it is evenly stirred, and use the dissolved solution as a base material;

[0029] Step 2: Weigh 25kg of small monomers of acrylic acid, 1.2kg of mercaptopropionic acid, 0.8kg of Vc and 1.5kg of ammonium persulfate and dissolve them in water, and add them dropwise to the stirring tank for 2 hours;

[0030] Step 3: Weigh 2 kg of hydrogen peroxide and directly add it to the stirring tank;

[0031] Step 4: Keep the high temperature at 60 degrees, and the reaction time is 6 hours to obtain the water-retaining agent.

Embodiment 2

[0033] Step 1: Weigh 450 kg of polyether macromonomer, put it into a stirring tank, add water until it is evenly stirred, and use the dissolved solution as a base material;

[0034] Step 2: Weigh 31.25kg of small monomer of acrylic acid, 1.5kg of mercaptopropionic acid, 1kg of Vc and 1.875kg of ammonium persulfate, dissolve them in water, and add them dropwise to the stirring tank for 2 hours;

[0035] Step 3: Weigh 2.5kg of hydrogen peroxide and directly add it to the stirring tank;

[0036] Step 4: Keep the high temperature at 60 degrees, and the reaction time is 6 hours to obtain the water-retaining agent.

Embodiment 3

[0038] Step 1: Weigh 922.5 kg of polyether macromonomer, put it into a stirring tank, add water until it is evenly stirred, and use the dissolved solution as a base material;

[0039] Step 2: Weigh 64kg of small monomers of acrylic acid, 3.075kg of mercaptopropionic acid, 2.05kg of Vc and 3.84kg of ammonium persulfate and dissolve them in water, and add them dropwise to the stirring tank for 2 hours;

[0040] Step 3: Weigh 5.125 kg of hydrogen peroxide and directly add it to the stirring tank;

[0041] Step 4: Keep the high temperature at 60 degrees, and the reaction time is 6 hours to obtain the water-retaining agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com