Rewinding roll for rewinding machine

A technology of rewinding roller and rewinding machine, applied in the field of rewinding machine, can solve the problems of small adsorption force of paper, discontinuous width direction of adsorption force, inability to produce, etc., achieve uniform axial force, and enhance paper adaptability , The effect of not easy to wrinkle the paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] see figure 1 , figure 1 It is an orthographic projection view of the cylindrical surface of the rewinding roller. The cylindrical surface 1 of the rewinding roller is provided with a plurality of slit-shaped suction ports 2, and every three slit-shaped suction ports 2 are arranged on the same generatrix of the cylindrical surface Above, the length direction of the slit-shaped suction port 2 is parallel to the axial direction of the rewinding roller. As a preferred embodiment, the length of each slit-shaped suction port 2 is not less than a quarter of the width of the paper adsorbed on the rewinding roller. exist figure 1 In the shown embodiment, the length L of each slit-shaped suction port 2 is approximately equal to one-third of the width of the paper adsorbed on the rewinding roller. The width W of each slit-shaped suction port 2 is preferably not greater than 4 millimeters.

Embodiment 2

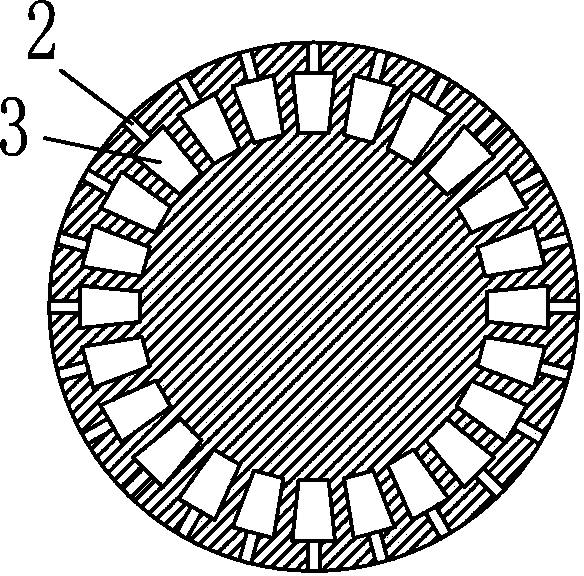

[0021] see figure 2 , figure 2 Also an orthographic view of the cylindrical surface of the winding roll. This embodiment and figure 1 The difference is that there is only one slit-shaped suction port 2 on the same generatrix of the cylindrical surface of the rewinding roller, and the two ends of the slit-shaped suction port 2 are connected to the paper that is adsorbed on the rewinding roller. The distance between the edges is not greater than 100 mm. that is figure 2 The dimension S marked in is not greater than 100 mm ( figure 2 The dotted line in indicates the paper picked up by the rewind roller). Compared with Embodiment 1, this embodiment not only reduces the number of slit-shaped suction ports 2, simplifies the structure of the rewinding roller, but also makes the adsorption force of the rewinding roller to the paper more continuous in the width direction of the paper. For other structural features of this embodiment, reference may be made to Embodiment 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com