Automatic mark replacement system for cigarette conveying equipment and detection method

A bar cigarette conveying system and automatic technology, applied in the directions of transportation and packaging, packaging automatic control, packaging, etc., can solve problems such as aggravating hidden dangers of quality accidents, quality accidents, and asynchrony of packaging machine bar cigarette conveying systems, so as to ensure consistent production. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

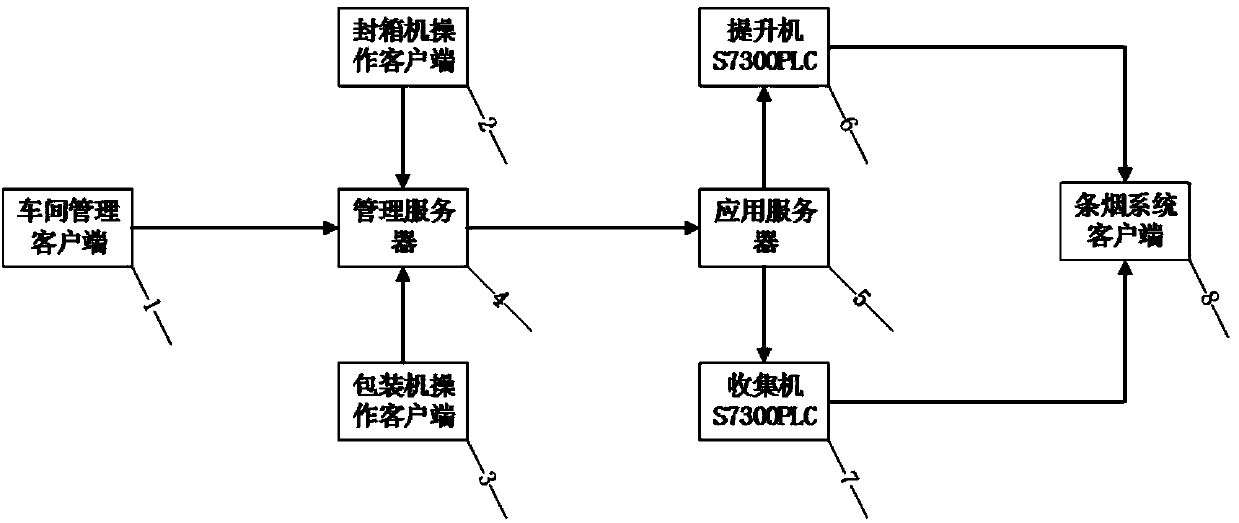

[0031] Such as figure 1 As shown, the present invention provides an automatic brand changing system for cigarette sticks conveying system, including workshop management client 1, sealing camera operation client 2, packaging machine operation client 3, management server 4, application server 5, elevator S7300PLC System 6, collector S7300PLC system 7, cigarette system client 8. The workshop management client 1, the sealing camera operation client 2 and the packaging machine operation client 3 are respectively connected to the management server 4. The camera sealing operation client 2 and the packaging machine operation client 3 are used to receive the production instruction for changing the cigarette brand issued by the workshop management client 1, and at the same time for the production personnel to perform the operation of chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com