Turnover type filtering, washing and drying machine and using method thereof

A washing and drying machine, flip-type technology, applied in the direction of non-progressive dryers, fixed filter elements, dryers, etc., can solve problems such as leakage, achieve convenience in use, avoid residues, and eliminate endogenous pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment, further illustrate the present invention.

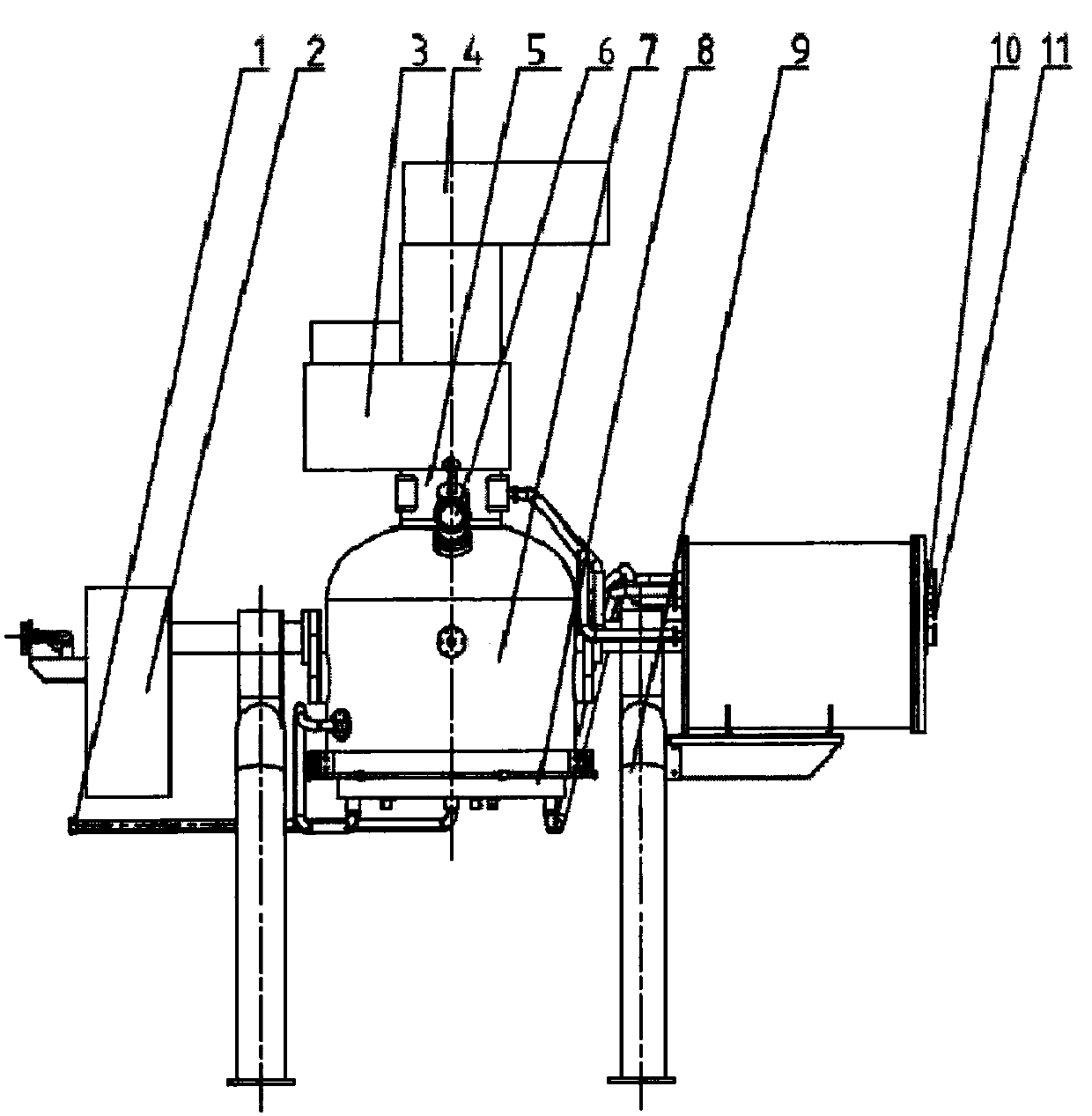

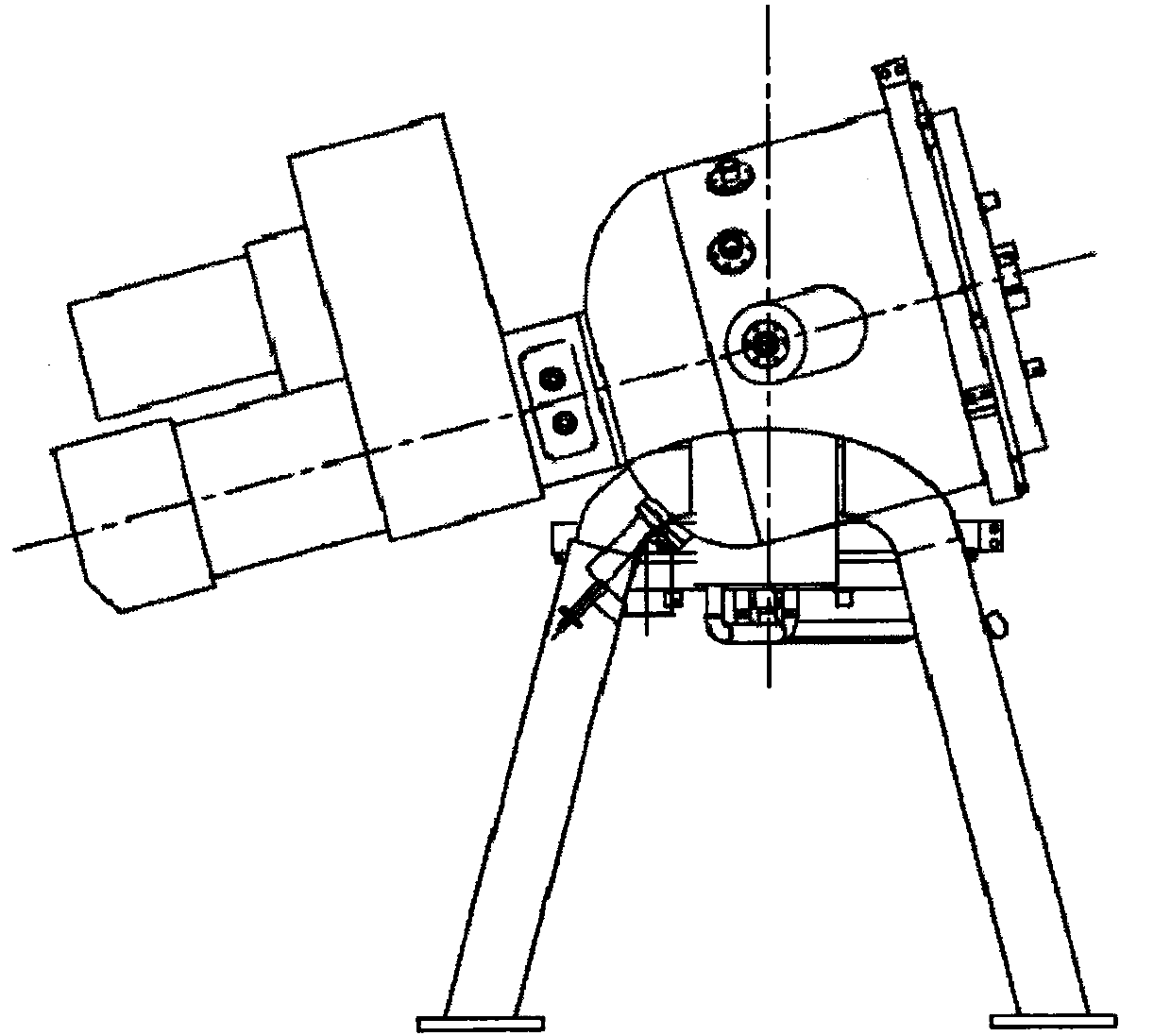

[0026] figure 1 The structural diagram of the flip-type filter washing and drying machine provided in this embodiment, the flip-type filter washing and drying machine includes a vacuum pumping and mother liquid discharge port system 1, and the vacuum pumping and mother liquid discharge port system 1 is connected to the filter bottom plate assembly 8 through pipelines , the filter bottom plate assembly 8 is connected to the container cavity 7, the upper head of the container cavity 7 is provided with a discharge port 6, and the upper head of the container cavity 7 is connected to the lifting stirring device 5 through a mechanical seal, and the lifting stirring device 5 passes through the first A motor 3 and a second motor 4 realize its ascension and rotation. The connecting shafts at both ends of the container cavity 7 are supported by the supporting device 9, and the container ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com