Glass printing technology

A glass and process technology, applied in printing, printing devices, etc., can solve the problems of low product rejection rate, lower production cost, and high production cost, and achieve the effect of low product rejection rate, reduced production cost, and guaranteed cleanliness.

Inactive Publication Date: 2014-12-03

成都派莱克科技有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The invention provides a glass printing process, which solves the technical problems of unreasonable design in the glass printing process in the prior art, high rejection rate of printed products, low production efficiency, and high production cost. Reasonable printing process design, low rejection rate of printed products, high production efficiency, and technical effects of reduced production costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0032] In Embodiment 1, a glass printing process is provided, please refer to figure 1 , the process includes:

[0033] S10, cleaning the glass;

[0034] S20, drying the cleaned glass;

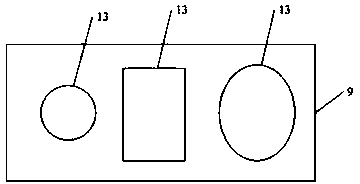

[0035] S30, fixing the dried glass on the fixture;

[0036] S40, flushing the surface of the glass on the fixture to be printed with an air pressure nozzle;

[0037] S50, printing the washed glass.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a glass printing technology which includes the following steps: firstly, cleaning a piece of glass; then drying the cleaned glass; then fixing the dried glass on a fixture; then scouring the surface, to be subjected to printing treatment, of the glass on the fixture through a pneumatic nozzle; finally performing printing treatment on the scoured glass. According to the invention, the technical effects that the glass printing technology is reasonably designed, the rejection rate of printed products is lower, the production efficiency is higher and the production cost is reduced are realized.

Description

technical field [0001] The invention relates to the field of industrial processing and manufacturing, in particular to a glass printing process. Background technique [0002] Glass often needs to be printed with inkjet during the manufacturing process, such as lens needs to make patterns, logos, etc. during the production process. [0003] In the prior art, a printing machine is mainly used for glass pattern printing, and the glass is placed on the printing platform and then printed. Due to the lack of effective treatment in the prior art, there are more impurities on the surface, and there are more waste products after printing. More, cause serious waste, cost becomes higher, and in the prior art, because ink printing is uneven, causes the product surface after printing to have white spots, causes more waste products, and production efficiency is low. [0004] To sum up, in the process of realizing the technical solution of the invention in the embodiment of the present ap...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B41M1/34

Inventor 林华业

Owner 成都派莱克科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com