Fiberboard with electromagnetic shielding function and preparation method thereof

An electromagnetic shielding and fiberboard technology, which is applied in the field of fiberboard and its preparation, can solve the problems of poor conductivity uniformity of electromagnetic shielding fiberboard, low carbon fiber doping efficiency, and low utilization rate of adhesive, so as to improve the uniformity of sizing and realize high efficiency. The effect of blending and simplifying the raw material processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

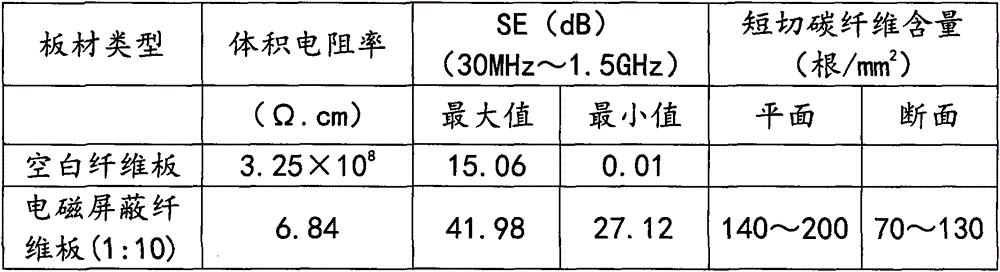

Embodiment 1

[0023] In this embodiment, 10mm chopped carbon fiber and miscellaneous wood fiber are mixed and hot-pressed to prepare a fiberboard with electromagnetic shielding function. The specific steps are as follows:

[0024] (1) Place the 10mm chopped carbon fiber and miscellaneous wood fiber in a variable speed mixer according to the mass ratio of 1:10 by the solution blending method and fully stir for 20 minutes to obtain evenly distributed mixed fibers;

[0025] (2) Place the mixed fibers in a blast drying oven and dry until the moisture content is 8% to 12%;

[0026] (3) fully stirring the isocyanate glue and the mixed fiber according to the mass ratio of 1:10 to obtain the sizing mixed fiber;

[0027] (4) Put the sizing mixed fiber in the disperser and fully disperse it for 20 minutes;

[0028] (5) Evenly pave the dispersed sizing mixed fibers in the molding frame, press with a hot press at 160°C and 12MPa for 6 minutes, and obtain a 360mm × 340mm × 3mm electromagnetic shielding...

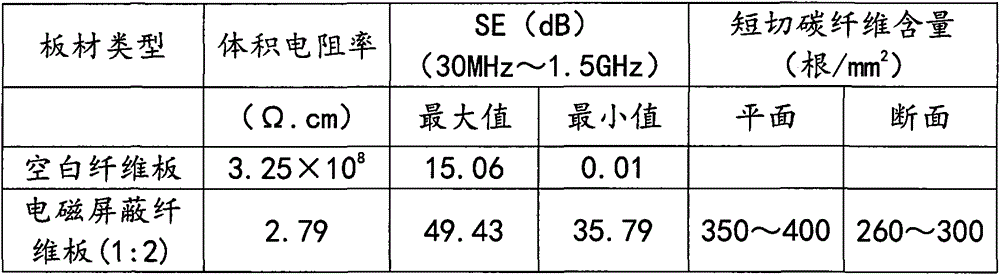

Embodiment 2

[0032] In this embodiment, 10mm chopped carbon fiber and miscellaneous wood fiber are mixed and hot-pressed to prepare a fiberboard with electromagnetic shielding function. The specific steps are as follows:

[0033] (1) Place the 10mm chopped carbon fiber and miscellaneous wood fiber in a variable speed mixer according to the mass ratio of 1:2 by the solution blending method and fully stir for 30 minutes to obtain evenly distributed mixed fibers;

[0034] (2) Place the mixed fibers in a blast drying oven and dry until the moisture content is 8% to 12%;

[0035] (3) fully stirring the isocyanate glue and the dispersed mixed fiber according to the mass ratio of 1:10 to obtain the sizing mixed fiber;

[0036] (4) Put the sizing mixed fiber in the disperser and fully disperse it for 20 minutes;

[0037] (5) Evenly pave the dispersed sizing mixed fibers in the molding frame, press with a hot press at 160°C and 12MPa for 6 minutes, and obtain a 360mm × 340mm × 3mm electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com