Continuous extrusion machine with symmetry plane of large surfaces of expanded cavity perpendicular to axis of extrusion wheel

A technology of symmetry plane and extruder, applied in the control equipment of metal extrusion, metal extrusion, metal processing equipment, etc., can solve the problems of poor rigidity, increase of spindle diameter, increase of manufacturing cost, etc., to reduce manufacturing cost and use cost, improve strength and rigidity, and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the present invention is not limited to specific embodiments.

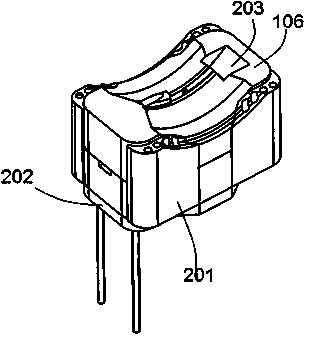

[0034] Extruder of the present invention such as figure 1 As shown, a rotating extrusion wheel 109 with an annular groove 111, the extrusion wheel 109 is installed on the prestressed spindle system of the tandem structure; a cavity 106 with an arc surface, the rotation of the arc surface The center is basically aligned with the axis 108 of the arc of the extrusion wheel 109, and a certain gap is kept between the two arc surfaces so that no direct contact occurs during work. There is a feed hole 503 on the cavity 106, which is connected to the feed hole. Connected is a billet expansion cavity 502; the arc-shaped feeding guide plate 103 is installed in the guide plate installation groove 203 above the arc surface of the cavity; the stopper block 107 is installed on the cavity, and its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com