Alprostadil freeze-drying cream and preparation method thereof

A technology of alprostadil and freeze-dried milk, which is applied in the direction of freeze-dried transportation, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of widening particle size distribution, improve stability and increase operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

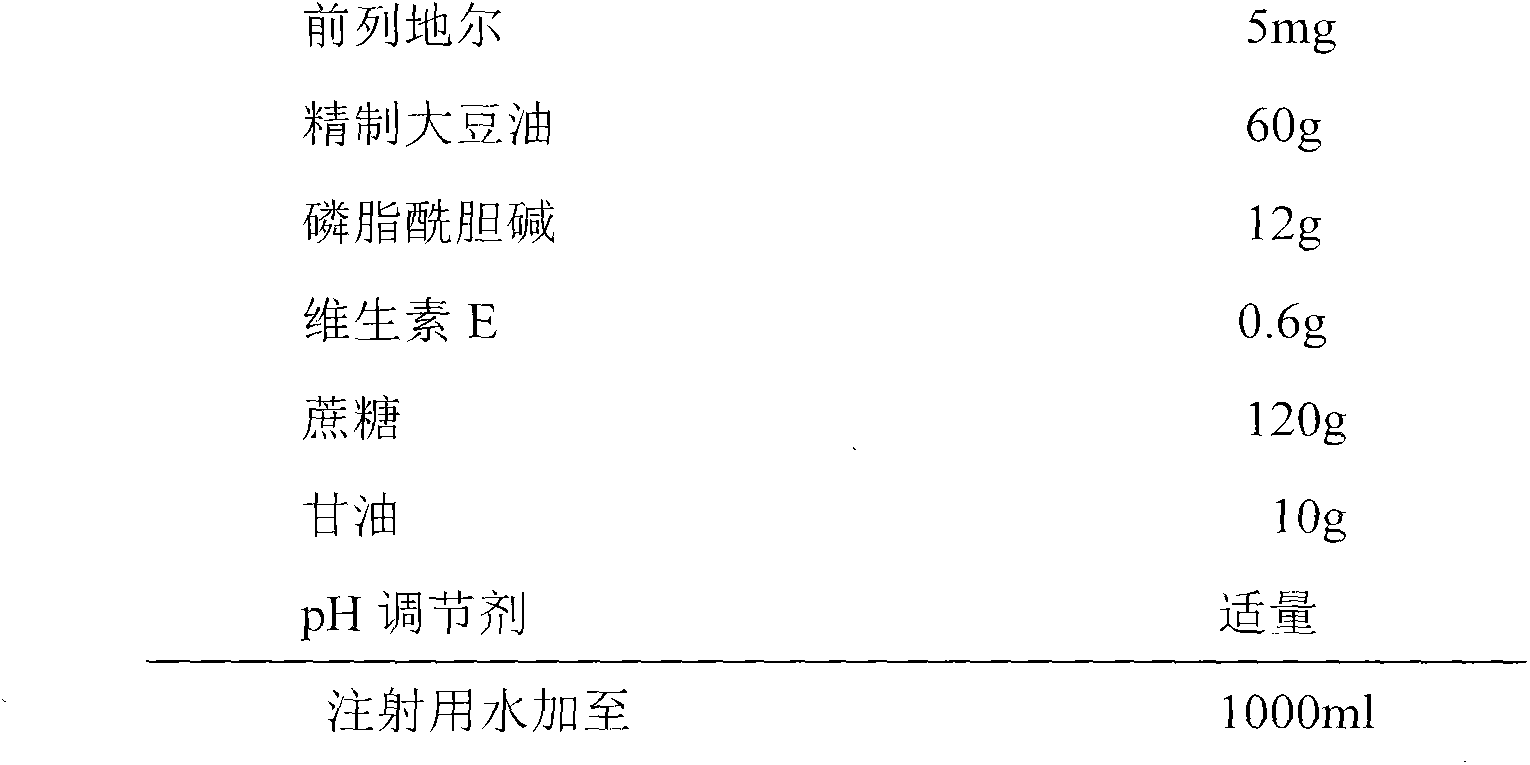

[0038] prescription:

[0039]

[0040] Process:

[0041] (1) Preparation of the water phase: add sucrose and glycerin into water to dissolve, heat to 65°C, and set aside;

[0042] (2) Preparation of the oil phase: heat the refined soybean oil to 65°C, add phosphatidylcholine (PC-98T, Shanghai Everite) and dissolve phosphatidylinositol respectively, add alprostadil, and stir to dissolve;

[0043] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 65°C, high-speed shear dispersion, shear speed of 10,000 rpm, and time of 15 minutes, to form colostrum

[0044] (4) High-pressure homogenization: adjust the pH of the colostrum in step (3) to 5.0-7.0, and then homogenize it through a microfluidizer for 3 times at a pressure of 1000-1200 bar;

[0045] (5) Preliminary filtration: Prefilter the refined milk in step (4) through a 0.45 μm filter membrane;

[0046] (6) Sterile filtration: the emulsion obtained in step (5) ...

Embodiment 2

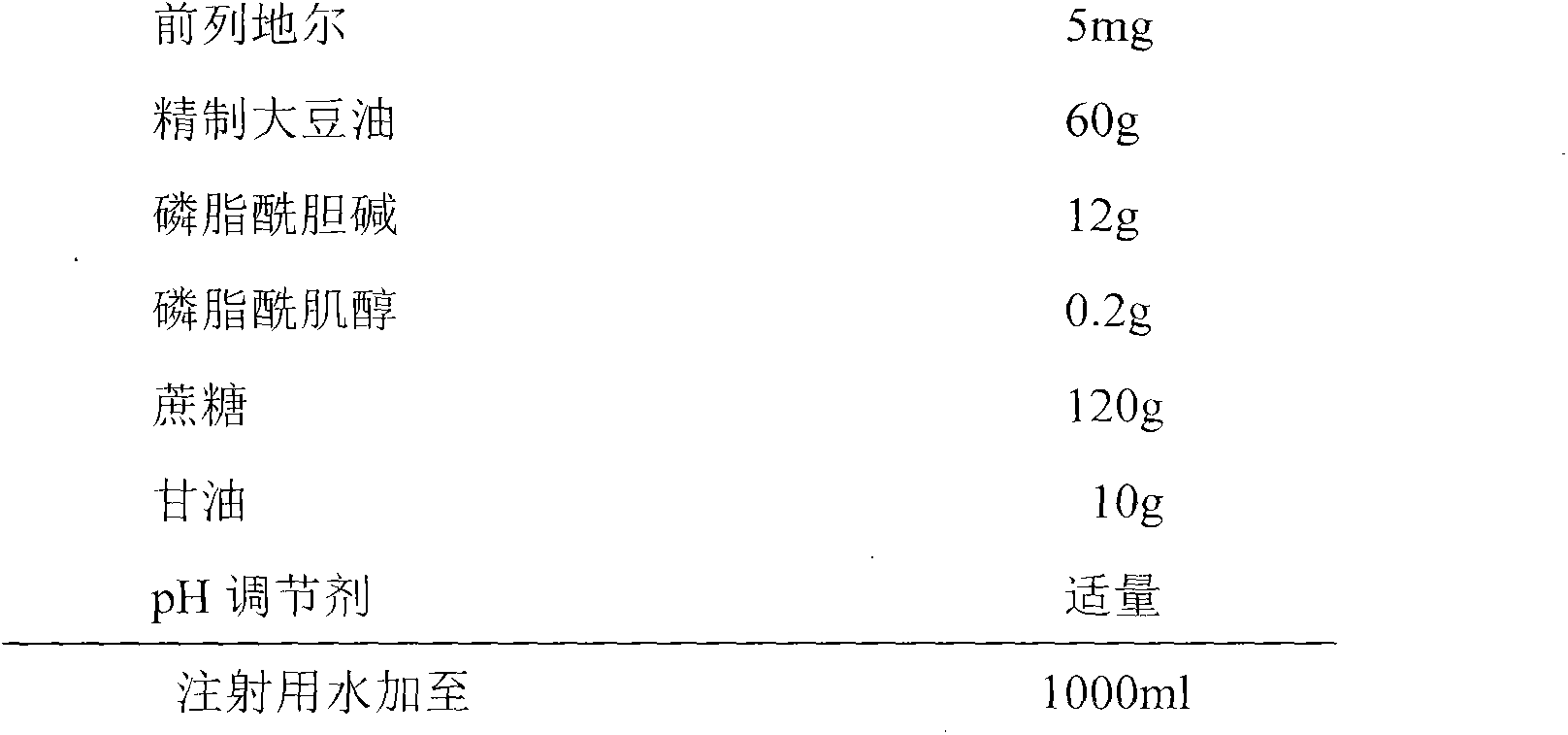

[0074] prescription:

[0075]

[0076]

[0077] Process:

[0078] (1) Preparation of water phase: add sucrose into water to dissolve, heat to 65°C, and set aside;

[0079] (2) Preparation of the oil phase: heat the refined soybean oil to 65°C, add phosphatidylcholine (PC-98T, Shanghai Everite) and dissolve phosphatidylinositol respectively, add alprostadil, and stir to dissolve;

[0080] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 65°C, high-speed shear dispersion, shear speed of 10,000 rpm, and time of 15 minutes, to form colostrum

[0081] (4) High-pressure homogenization: adjust the pH of the colostrum in step (3) to 5.0-7.0 with sodium hydroxide, and then use a microfluidizer for high-pressure homogenization 3 times at a pressure of 1000-1200 bar;

[0082] (5) Preliminary filtration: Prefilter the refined milk in step (4) through a 0.45 μm filter membrane;

[0083] (6) Sterile filtration: the em...

Embodiment 3

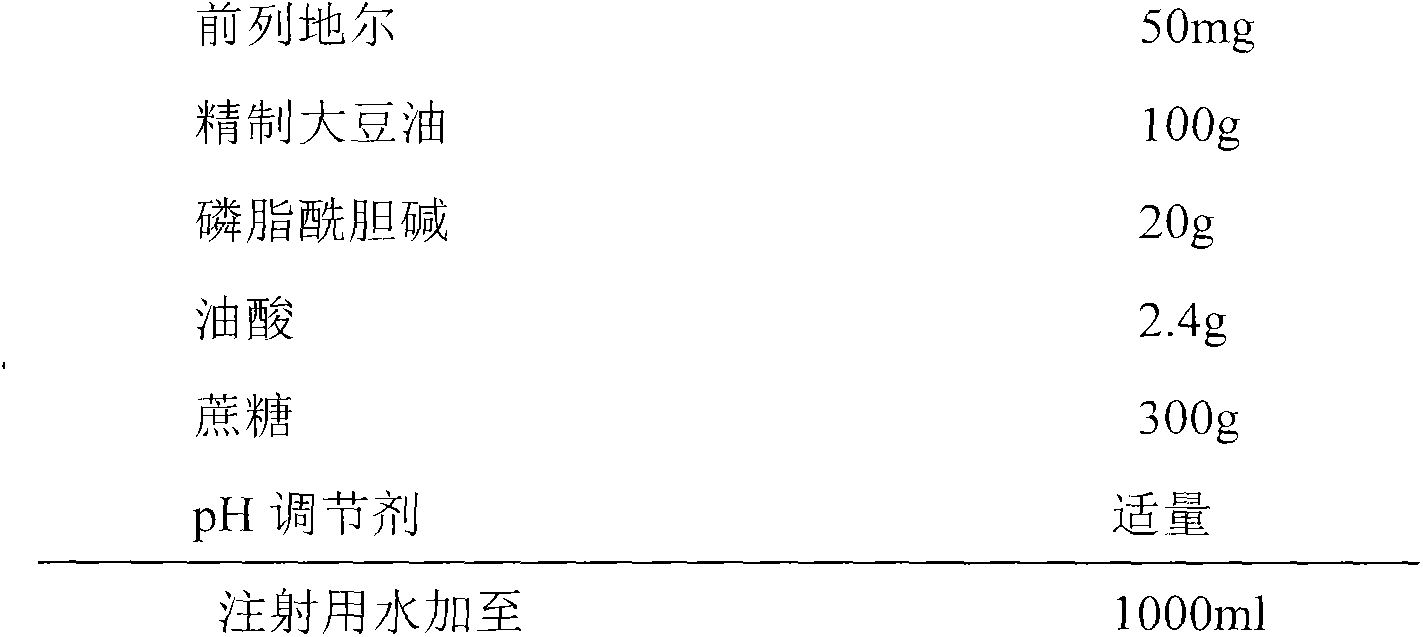

[0098] prescription:

[0099]

[0100] Process:

[0101] (1) Preparation of water phase: add sucrose into water to dissolve, heat to 65°C, and set aside;

[0102] (2) Preparation of oil phase: heat refined soybean oil to 65°C, add phosphatidylcholine (PC-98T) and phosphatidylinositol (PI) to dissolve respectively, add alprostadil, stir to dissolve;

[0103] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 65°C, high-speed shear dispersion, shear speed of 10,000 rpm, and time of 15 minutes, to form colostrum

[0104] (4) High-pressure homogenization: adjust the pH of the colostrum in step (3) to 5.0-7.0, and homogenize it through a microfluidizer for 3 times at a pressure of 1000-1200bar:

[0105] (5) Preliminary filtration: Prefilter the refined milk in step (4) through a 0.45 μm filter membrane;

[0106] (6) Sterile filtration: the emulsion obtained in step (5) is sterilized by filtration through a 0.22 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com