Aleurone layer steamed bun and making process thereof

The technology of aleurone layer and wheat aleurone layer is applied in the field of aleurone layer steamed bread and its production process, which can solve the problems of increasing production cost, affecting dough fermentation, and poor taste of steamed bread, so as to save resources, improve human immunity, Delicate taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] See attached figure 1 , wherein 1 represents the steamed steamed buns in this embodiment, and its components are as follows: the proportion of flour raw materials is 80% of high-gluten flour and 20% of the content of wheat aleurone layer; the mass ratio of the added auxiliary materials to the flour raw materials is: The amount of dry yeast is 1%-2%; fungal α-amylase 2-4PPM; xylanase 40-80PPM; vitamin C 5-15PPM; glucose oxidase 20-40PPM; water addition 45%-55%.

[0055] attached by figure 1 It can be seen that the color of the steamed buns steamed with this formula is light brown, the specific volume is almost the same as that of wheat flour steamed buns, and the steamed buns have a uniform structure and a full shape. At the same time, the steamed bun has a good taste and fully meets the edible requirements.

Embodiment 2

[0057] See attached figure 1 , wherein 2 represents the steamed buns steamed in this embodiment, and its components are as follows: the proportion of flour raw materials is 70% of high-gluten flour and 30% of the content of wheat aleurone layer; the mass ratio of the added auxiliary materials to the flour raw materials is: The amount of dry yeast is 1%-2%; fungal α-amylase 2-4PPM; xylanase 40-80PPM; vitamin C 5-15PPM; glucose oxidase 20-40PPM; water addition 45%-55%.

[0058] attached by figure 1 It can be seen that the steamed buns steamed with this formula are light brown in color, and the specific volume is slightly smaller than that of wheat flour steamed buns, but the steamed buns have uniform structure, full shape and smooth surface. At the same time, the steamed bun has a good taste and fully meets the edible requirements; moreover, because the content of the content of the wheat aleurone layer is increased, the steamed bun with the formula can provide richer nutrients...

Embodiment 3

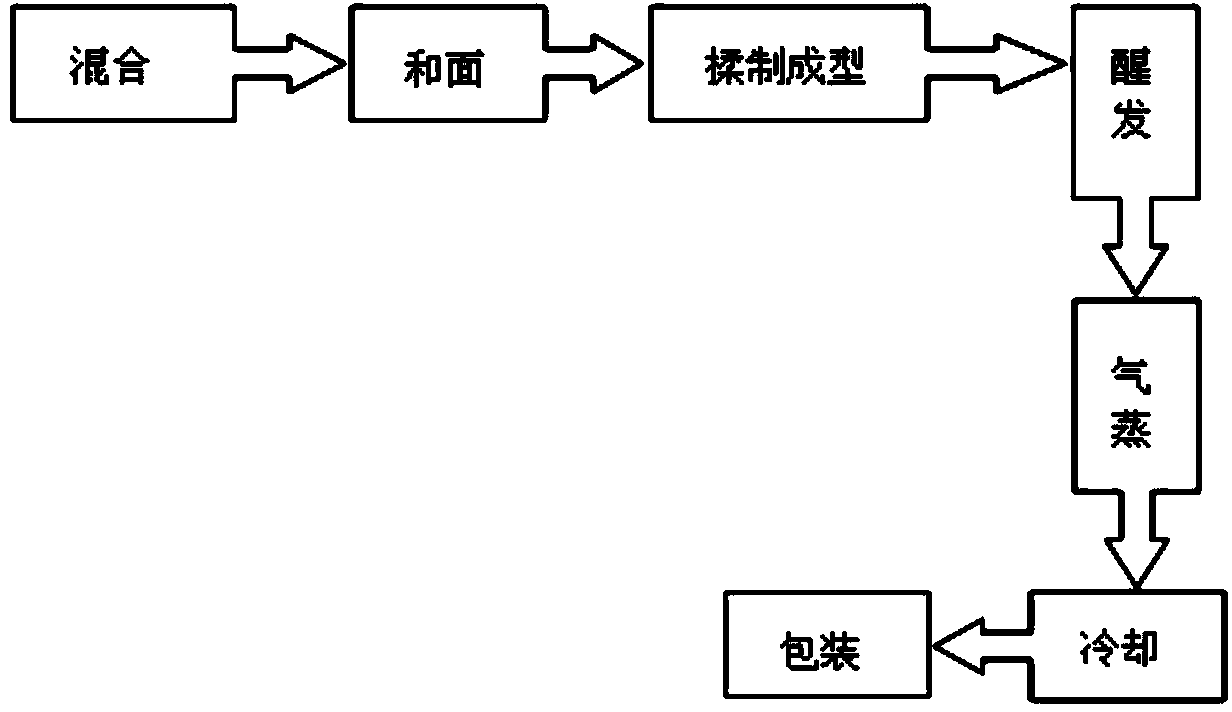

[0060] Refer to attached figure 2 The steaming process of steamed bread with aleurone layer of the present invention is described, and the steaming process includes the following steps: (1) mixing: mixing wheat aleurone layer content, high-gluten flour, fungal α-amylase, xylanase, vitamin C. Mix glucose oxidase and dry yeast for 20 minutes; (2) Kneading dough: Preheat the dough mixing bowl to 32°C, put the above mixed materials into the mixing bowl, add 45% to 55% water, and start Mixing machine, knead the dough for 5-10 minutes; (3) Forming: press the dough 8-15 times until the skin is smooth and flat, and make steamed buns; (4) proofing: ferment the steamed buns in the fermentation box for 35-60 minutes , where the temperature of the proofing box is 35°C to 37°C, and the relative humidity is 80% to 85%; (5) steaming: steaming in a boiling water pot for 18 to 22min, wherein the pressure of steaming is 0.25 to 0.35MP , then remove and cool to room temperature. Then it can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com