Multifunctional solid leaf trimming machine

A leaf shearing machine and multi-functional technology, which is applied in the direction of agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve the problems of poor resource integration, waste of manpower and material resources, etc., and achieve high work efficiency, saving investment and expenses, and economic benefits maximized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

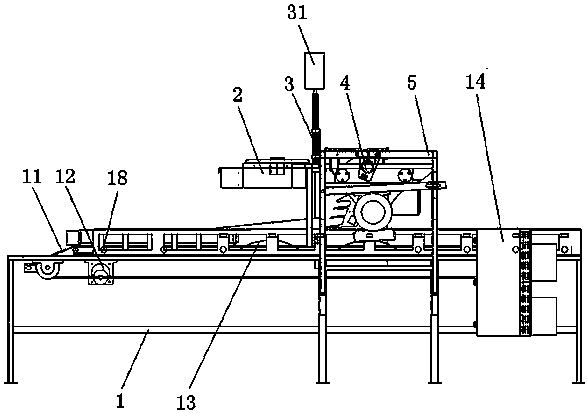

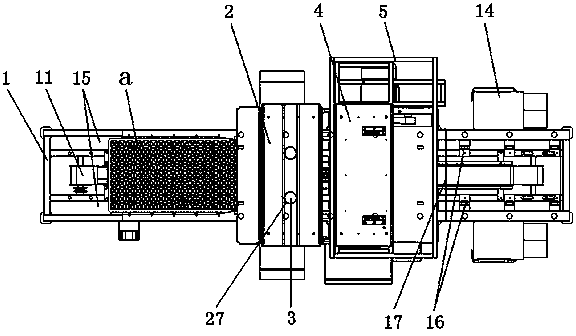

[0027] The multifunctional three-dimensional leaf trimmer provided by the present invention comprises a frame 1, a conveyor belt 11 located on the frame 1 and a residual leaf collection box 14 located at the tail end of the conveyor belt 11, wherein the frame 1 is provided with a shearing top on it. Knife group 2, knife rest 5 of blade group 4, wherein:

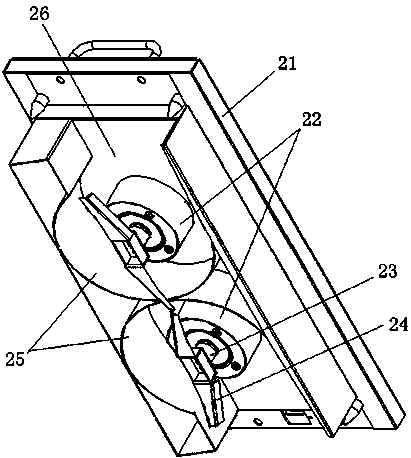

[0028] The top shearing cutter group 2 includes a top plate 21, and two power motors 22 arranged on the top plate 21, the output shaft of each power motor 22 is connected with the cutter shaft 23 of the blade 14 by a coupling, Driven by the power motor 22, the cutter shaft 23 and the blade 14 are rotated so as to cut off the top tobacco leaves; The fence 25 introduces the trimmed tobacco leaves into it and then discharges them through the leaf discharge port 26 to prevent the tobacco leaves from splashing, and at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com