A graphite sheet/self-assembled nanometer cobalt tetraoxide lithium ion negative electrode material, preparation method and lithium battery using the same

A technology of lithium tricobalt tetroxide and negative electrode material is applied in the field of lithium ion energy storage materials, which can solve the problems of reducing the conductivity of graphene, affecting the characteristics of electrode materials, and low graphene coverage, avoiding redeposition, promoting rapid transmission, and improving Effects of Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

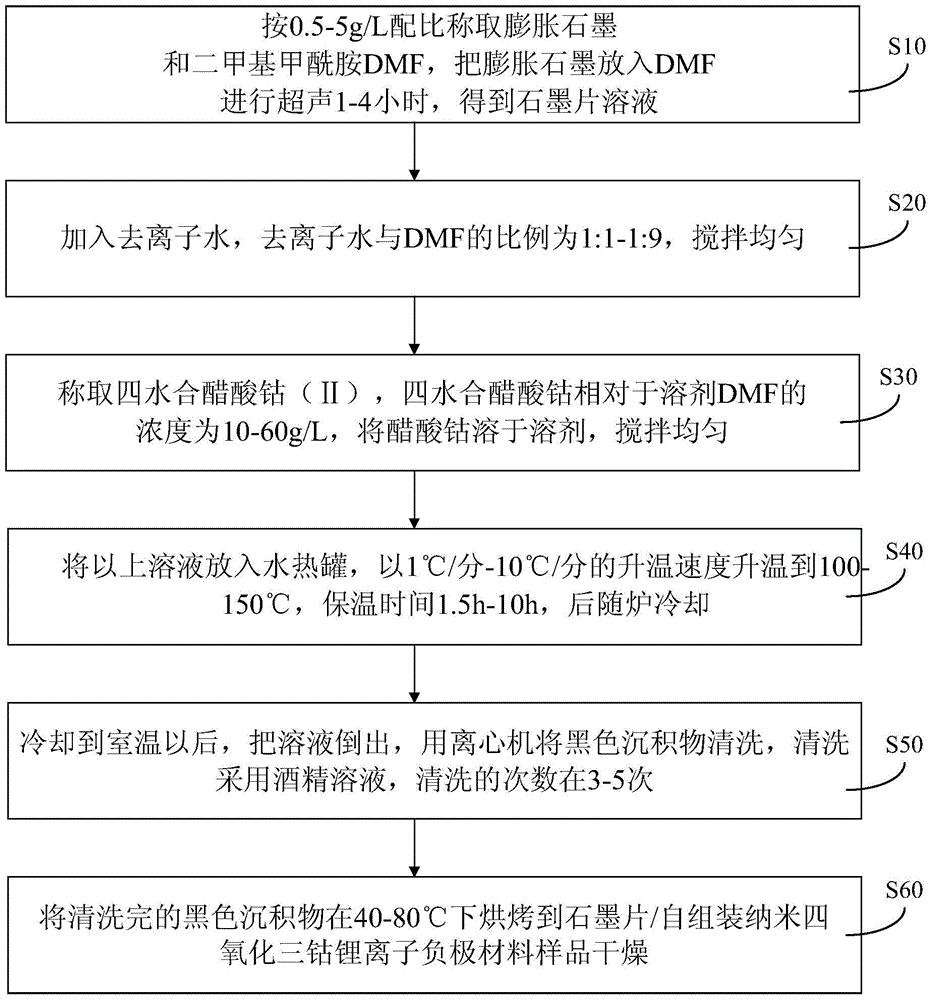

[0036] see figure 1 , shows a method for preparing a graphite sheet / self-assembled nanometer cobalt tetraoxide lithium ion negative electrode material according to an embodiment of the present invention, comprising the following steps:

[0037] S10, weighing the expanded graphite and dimethylformamide DMF according to the ratio of 0.5-5g / L, putting the expanded graphite into the DMF and ultrasonicating for 1-2 hours to obtain a graphite flake solution;

[0038] S20, add deionized water, the ratio of deionized water to DMF is 1:1-1:9, stir evenly;

[0039] S30, weigh cobalt acetate tetrahydrate, wherein cobalt is II valence, referred to as cobalt (II) acetate tetrahydrate, the concentration of cobalt acetate tetrahydrate (II) relative to the solvent DMF is 10-60g / L, dissolve cobalt acetate tetrahydrate In the solvent, stir and dissolve evenly;

[0040] S40, put the above solution into the hydrothermal tank, wherein the filling volume ratio of the hydrothermal tank is 1 / 5-1 / 2,...

Embodiment 1

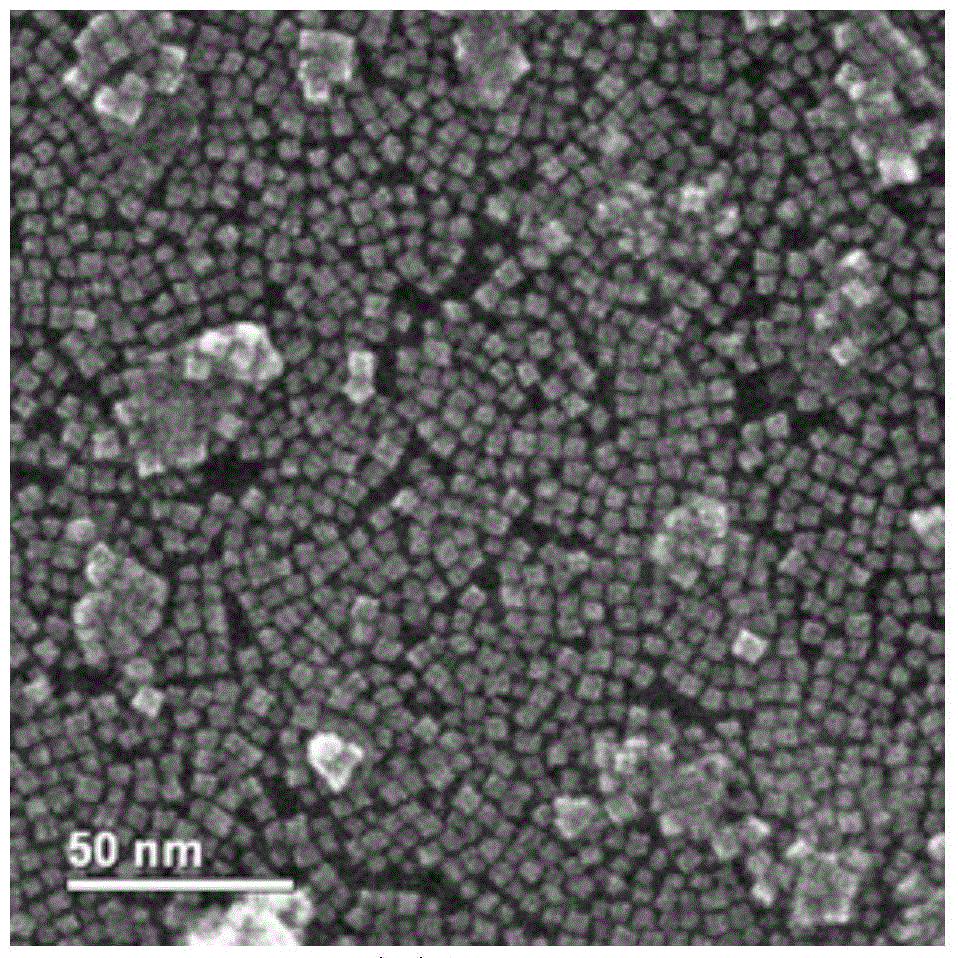

[0048] Weigh 4 mg of expanded graphite and 8 ml of DMF, put the expanded graphite into DMF and perform ultrasonication for 1 hour to obtain a graphite flake solution. Weigh 0.9ml of deionized water, add the graphite flake solution, and stir evenly. Weigh 80 mg of cobalt (II) acetate tetrahydrate, dissolve the cobalt (II) acetate tetrahydrate in the mixed solvent, and stir until completely dissolved. Put the above solution into a hydrothermal tank with a volume of 20ml. The reaction solution accounts for about 44.5% of the total volume of the hydrothermal tank, which meets the requirements of the filling volume ratio of the hydrothermal tank. The temperature is raised to 120 °C at a heating rate of 1 °C / min. The holding time is 1.5h, and then it is cooled with the furnace. The microparticles are cleaned with a centrifuge, using alcohol solution, and the number of times of cleaning is 3 times. Bake at 40°C until the sample is dry to obtain a graphite sheet / self-assembled nanom...

Embodiment 2

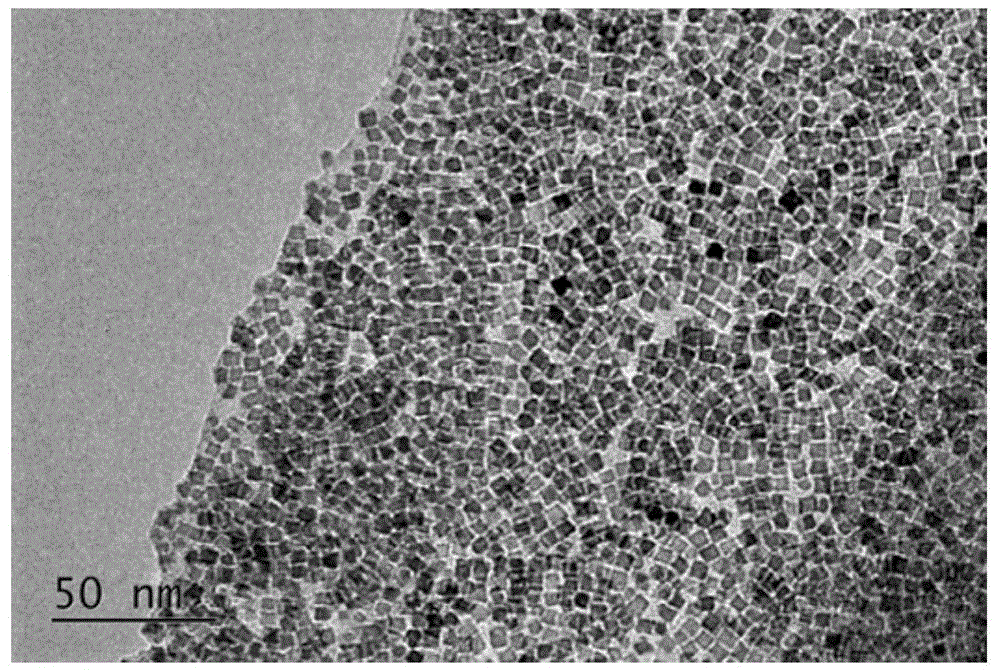

[0050] Weigh 40 mg of expanded graphite and 8 ml of DMF, put the expanded graphite into DMF and perform ultrasonication for 2 hours to obtain a graphite flake solution. Weigh 8ml of deionized water, add the graphite flake solution, and stir evenly. Weigh 480 mg of cobalt (II) acetate tetrahydrate, dissolve the cobalt (II) acetate tetrahydrate in the mixed solvent, and stir until completely dissolved. Put the above solution into a 50ml hydrothermal tank. The reaction solution accounts for about 32% of the total volume of the hydrothermal tank, which meets the requirements of the filling volume ratio of the hydrothermal tank. The temperature is raised to 150 °C at a heating rate of 5 °C / min. 5h, then cool down with the furnace. The microparticles are cleaned with a centrifuge, using alcohol solution, and the number of times of cleaning is 4 times. Bake at 80°C until the sample is dry to obtain a graphite sheet / self-assembled nanometer cobalt tetraoxide lithium ion negative ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com