Shock waveform peak measurement method based on quadratic curve fitting

A technology of quadratic curve and shock waveform, which is applied in the peak measurement of shock waveform and the peak measurement field of shock waveform, which can solve the problems affecting the measurement accuracy, not completely suitable for half-sine and Gaussian shape shock waveforms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

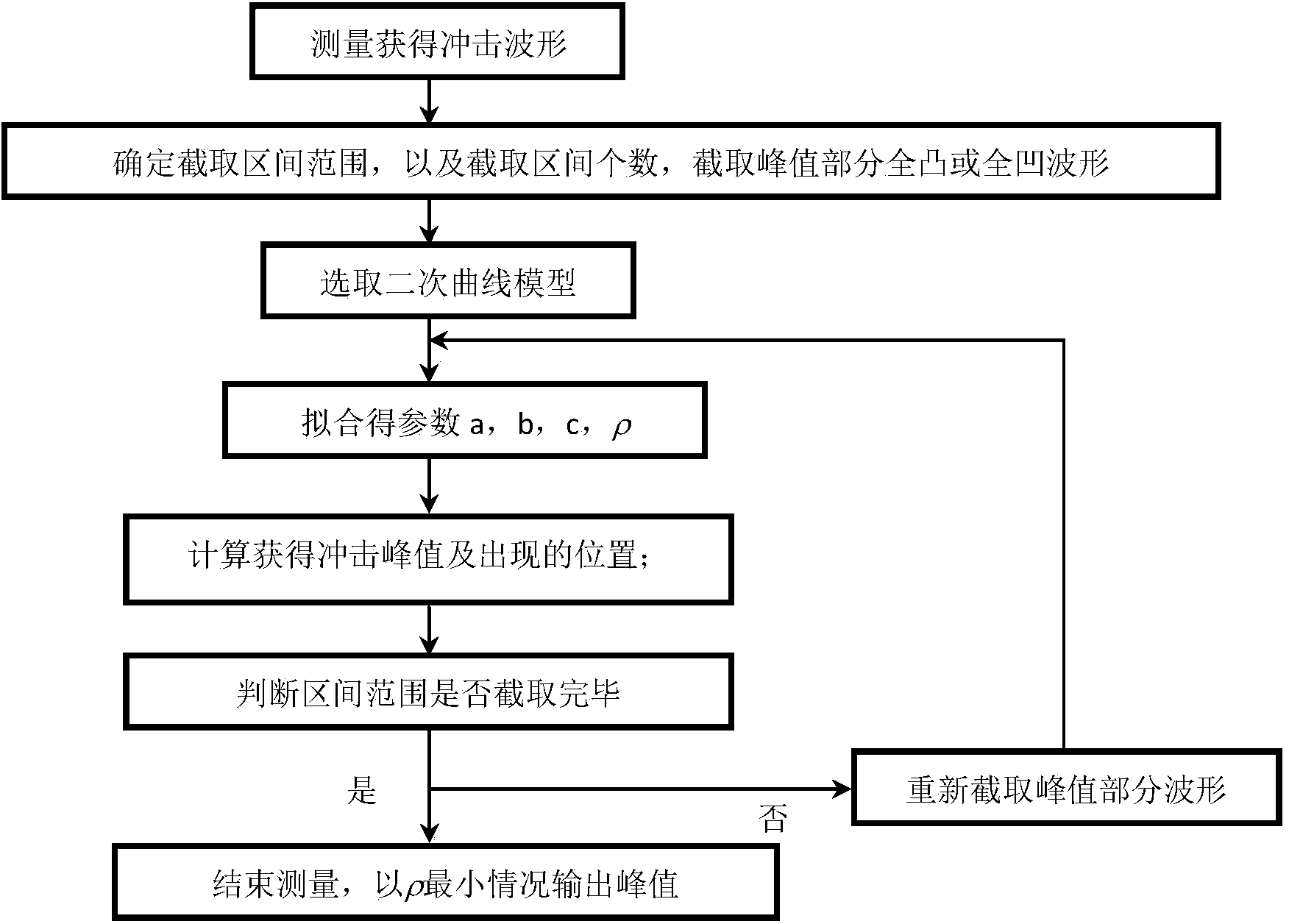

[0043] The implementation of the method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] A method for measuring the peak value of a shock waveform based on quadratic curve fitting, the specific steps of which include:

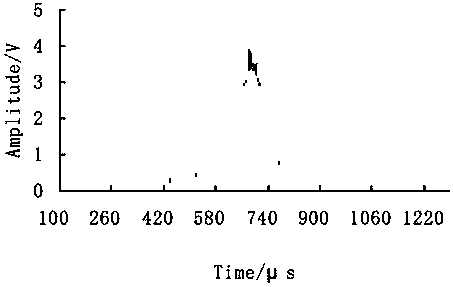

[0045] Step 1, such as figure 1 As shown, the shock excitation source is used to generate a waveform, which is similar to the half-sine shock excitation. The sensor and the supporting waveform data acquisition system are used for waveform measurement to obtain a complete sampling sequence of the shock measurement waveform at equal intervals.

[0046] Step 2. Obtain the maximum value of 3.8V and the minimum value of 0.2V of the shock waveform by comparison method;

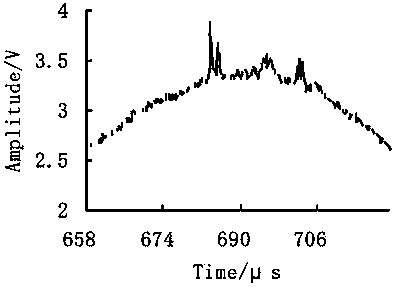

[0047] Step 3: intercept the fully convex (or fully concave) portion of the shock waveform between the maximum value of 3.8V and the minimum value of 0.2V for peak calculation. Here, with the peak position as the center, 5 intervals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com