A resistive deflection measuring device

A deflection measurement, resistive technology, applied in the field of deflection measurement, can solve the problems of insufficient accuracy and stability, difficult to meet accuracy and linearity, and difficult to meet the accuracy requirements, and to achieve a wide range of applications, high accuracy and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

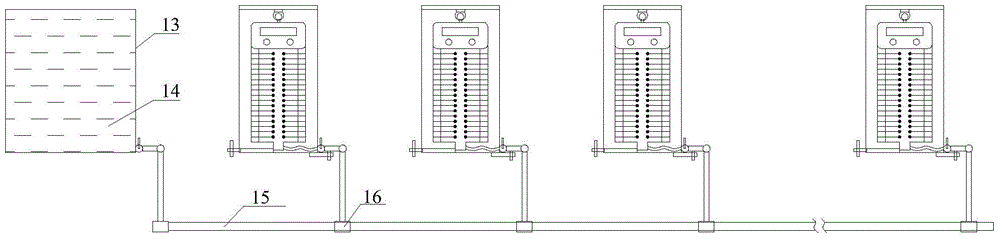

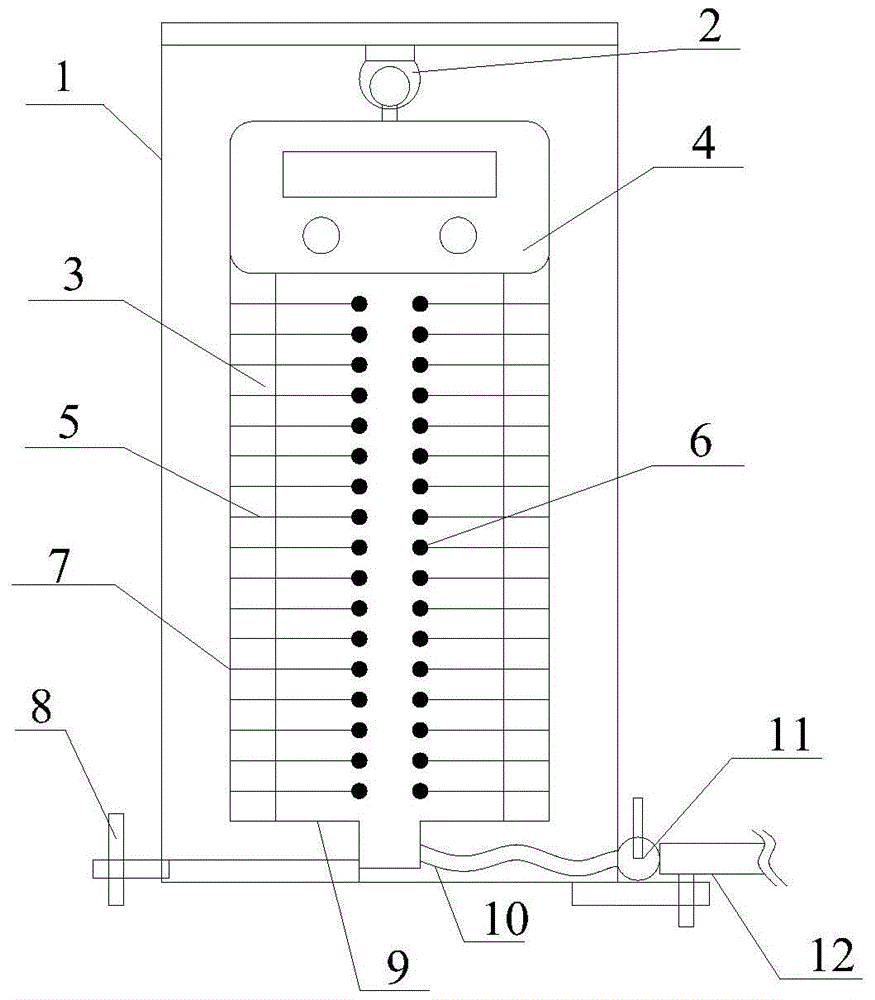

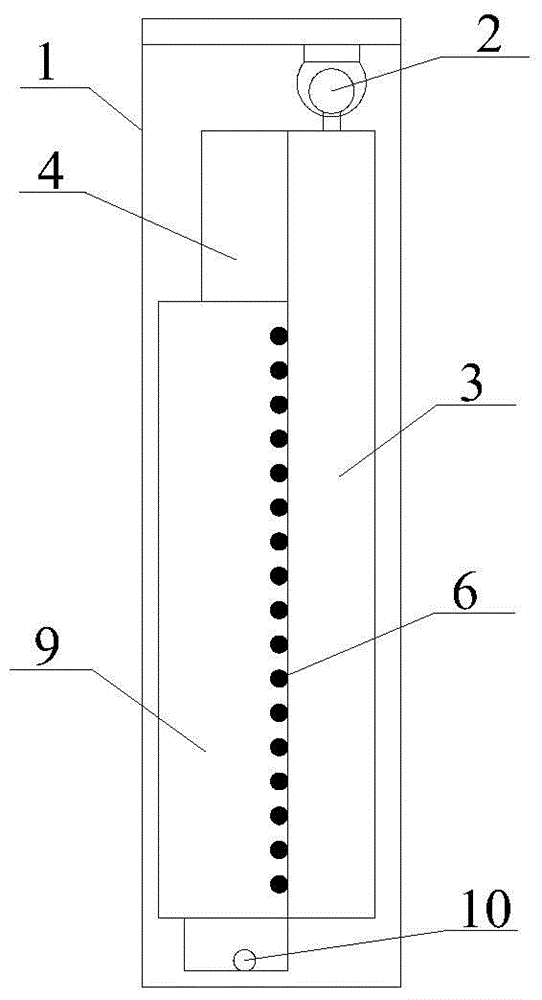

[0038] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the resistive deflection measuring device of the present invention comprises a transparent outer frame (1), a hinged ball (2), a circuit board (3), a wireless transceiver (4), an insulation resistance needle (5), a conductive resistance head ( 6), resistance rod (7), leveling screw (8), semi-cylindrical transparent standpipe (9), flexible pipe (10), valve joint (11) and connecting capillary (12).

[0039] Such as figure 2As shown, the semi-cylindrical transparent standpipe (9) is located in the transparent outer frame (1), and the resistance rod (7), the insulation resistance needle (5) and the conductive resistance head (6) are customized on the circuit board (3). The cylindrical transparent standpipe (9) and the wireless transceiver device (4) are fixedly clamped on the circuit board (3), the circuit board (3) has a certain thickness, and its upper end is connected with the transparent outer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com