Double-station pneumatic fixture

A pneumatic clamp and double-station technology, applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of clamping effect and cylinder volume and environmental protection, and achieve the realization of compact structure of the clamp, simple structure, lifting clamp The effect of the tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

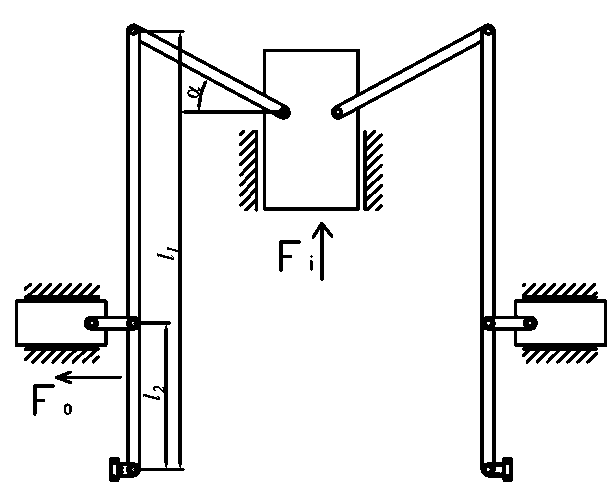

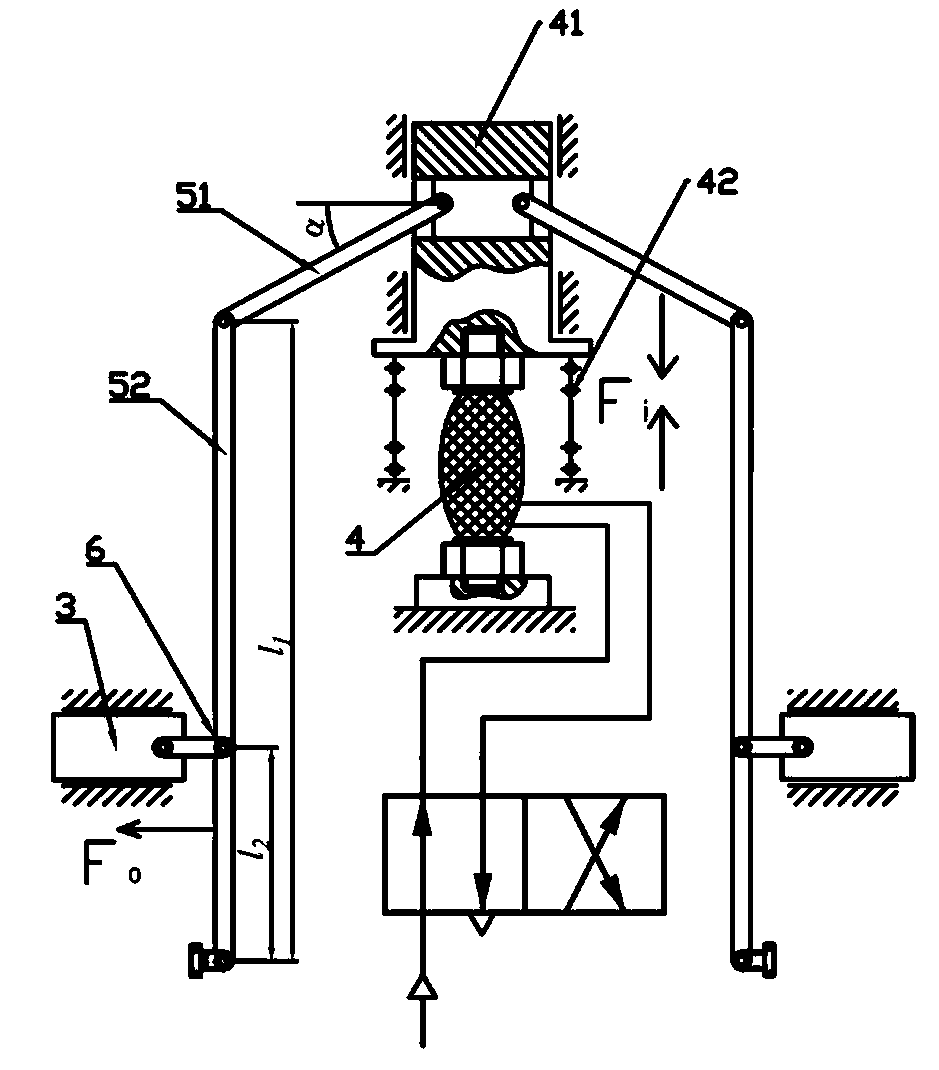

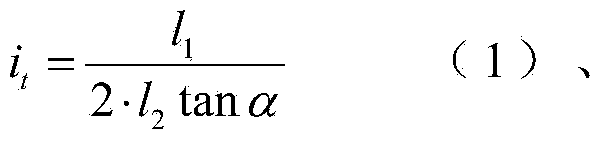

[0011] The invention innovatively proposes a double-station pneumatic clamp, which solves the contradiction and difficult problem between the clamping pressure of the pneumatic clamp and the cylinder volume.

[0012] Such as figure 2 As shown, the double-station pneumatic clamp consists of an air pump (not shown), a pneumatic tendon 4, two sets of push rod mechanisms and two clamping elements 3. There is also a two-station for output control between the above-mentioned air pump and the pneumatic tendon. Position four-way valve 2. The pneumatic tendon 4 is a driving source capable of radial expansion and axial contraction after being filled with compressed air. One end of the pneumatic tendon is fixed, and the other end is connected with a coaxially telescopic piston rod 41, and the bottom of the piston rod is fixed with Reset spring 42. By filling compressed air into the pneumatic tendon, the pneumatic tendon then generates an axial tensile force. In order to meet the require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com