Unloading device for spring steel straightening and shearing machine

A shearing machine and spring steel technology, which is applied in the field of spring steel straightening shearing machine and the blanking device of spring steel straightening shearing machine, can solve the problem of unsightly bundling and forming, confusion of spring steel crosses, and inconvenient punching. baling and other issues, to avoid damage to the surface of the spring steel, avoid crossover, and facilitate transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

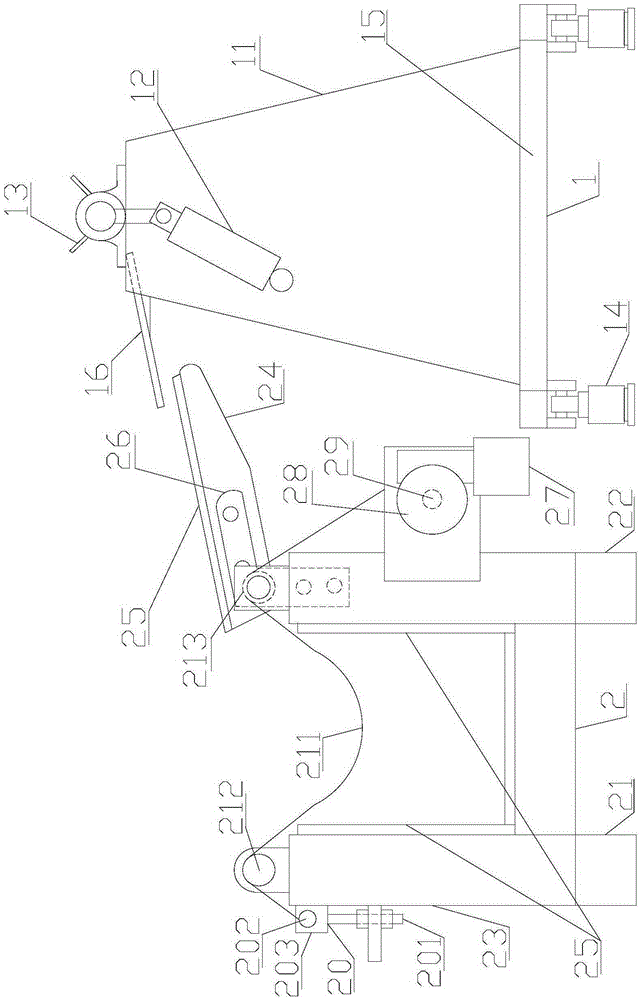

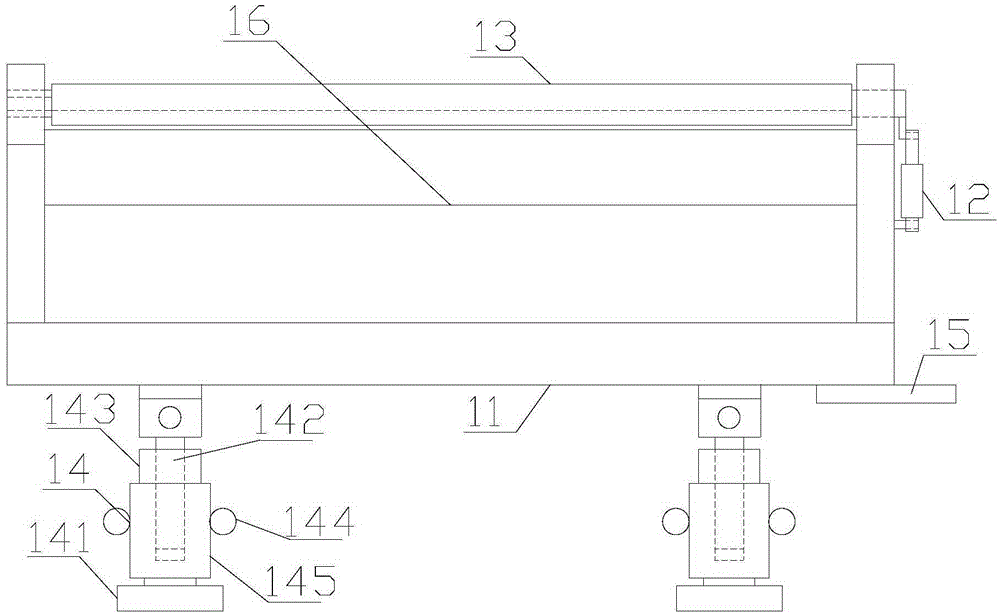

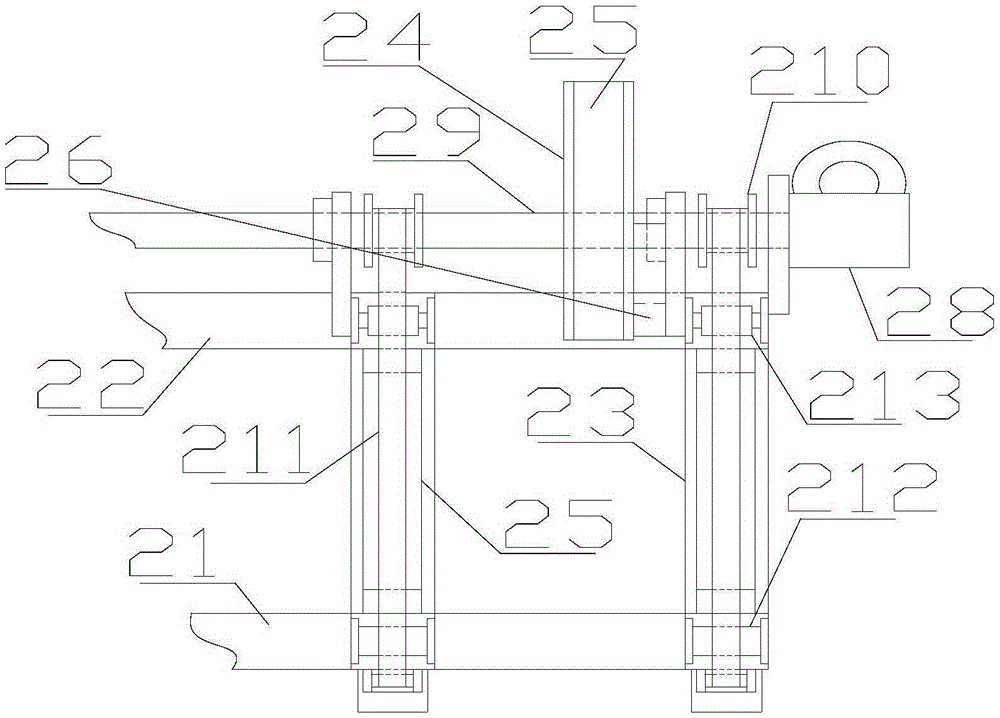

[0022] refer to figure 1 , figure 2 ,and image 3, a blanking device of a spring steel straightening and shearing machine of the present invention, comprising a blanking rack 1 and a storage rack 2, the front of the blanking rack 1 is provided with a storage rack 2, and the blanking rack 1 includes Frame body 11, hydraulic cylinder 12, translation trough 13, adjustable support seat 14, collection tray 15 and first transition plate 16, the bottom of said frame body 11 is provided with adjustable support seat 14, on said frame body 11 A translation trough 13 and a first transition plate 16 are installed, the first transition plate 16 is provided below the translation trough 13, a plastic pad is provided on the inner wall of the translation trough 13, and the translation trough 13 It is an equilateral angle steel, the rear side of the frame body 11 is provided with a hydraulic cylinder 12, the piston rod of the hydraulic cylinder 12 is connected with the translation trough 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com