Grid type grain storage warehouse

A grid-type and warehouse technology, applied in fruit hanging devices, botany equipment and methods, gardening, etc., can solve the problems of grains being prone to mildew, and achieve the effects of preventing moisture and mildew, increasing air permeability, and ensuring air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

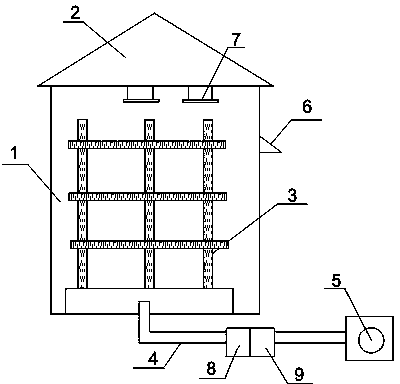

[0019] Such as figure 1 As shown, a grid-type grain storage warehouse includes a warehouse composed of a wall 1 and a ceiling 2, and a grid-type partition wall 3 composed of a vertical partition and a horizontal partition is arranged in the warehouse. Both the dividing plate and the horizontal dividing plate are hollow plates made of double-layer grids, and the inner cavities of the vertical dividing plate and the horizontal dividing plate are connected to the blower 5 through the blowing duct 4, and the blowing duct 4 is also connected with a Air dryer8.

Embodiment 2

[0021] On the basis of the structure of Example 1, various auxiliary settings can be set according to actual needs, including adding an air heater 9 on the blast duct 4 to heat the incoming air, thereby enhancing the ventilation and drying of the grain. Of course, it is also possible to strengthen the air circulation in the warehouse by setting exhaust fan 6 on body of wall 1, and to set infrared heating lamp 7 on ceiling 2 to control the humidity and temperature in the warehouse. These measures can prevent grain from going moldy. Improve the quality of grain storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com