Avoidance of continuous operation in frequency converter-stimulated torsion resonances of a compressor train

A technology of compressor unit and frequency converter, applied in the field of compressor unit, can solve problems such as high cost, and achieve the effects of reliable component damage and fail-safe service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

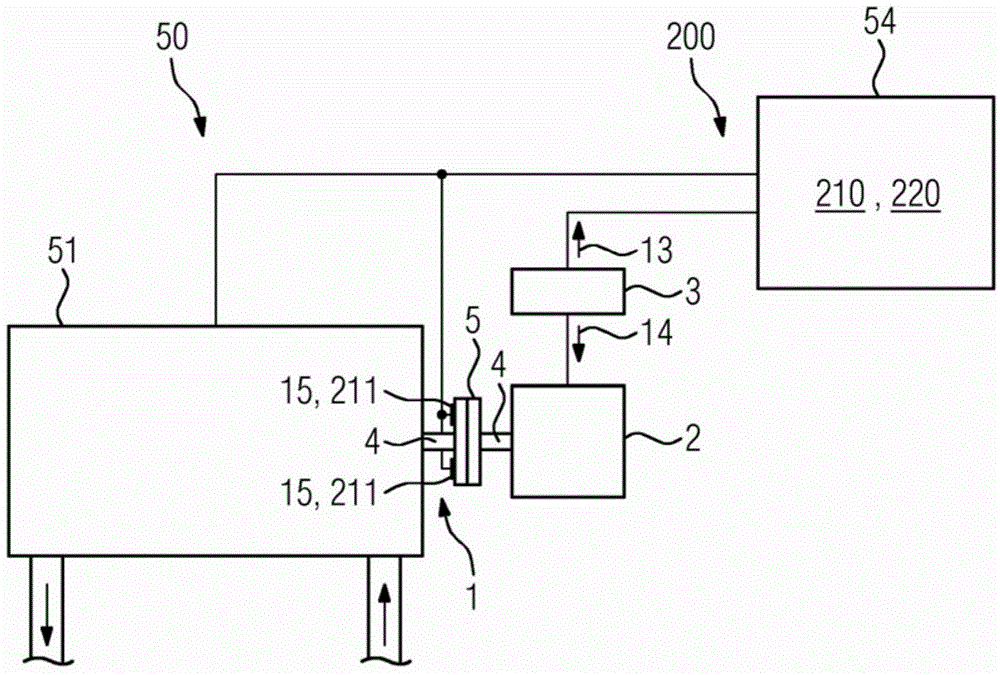

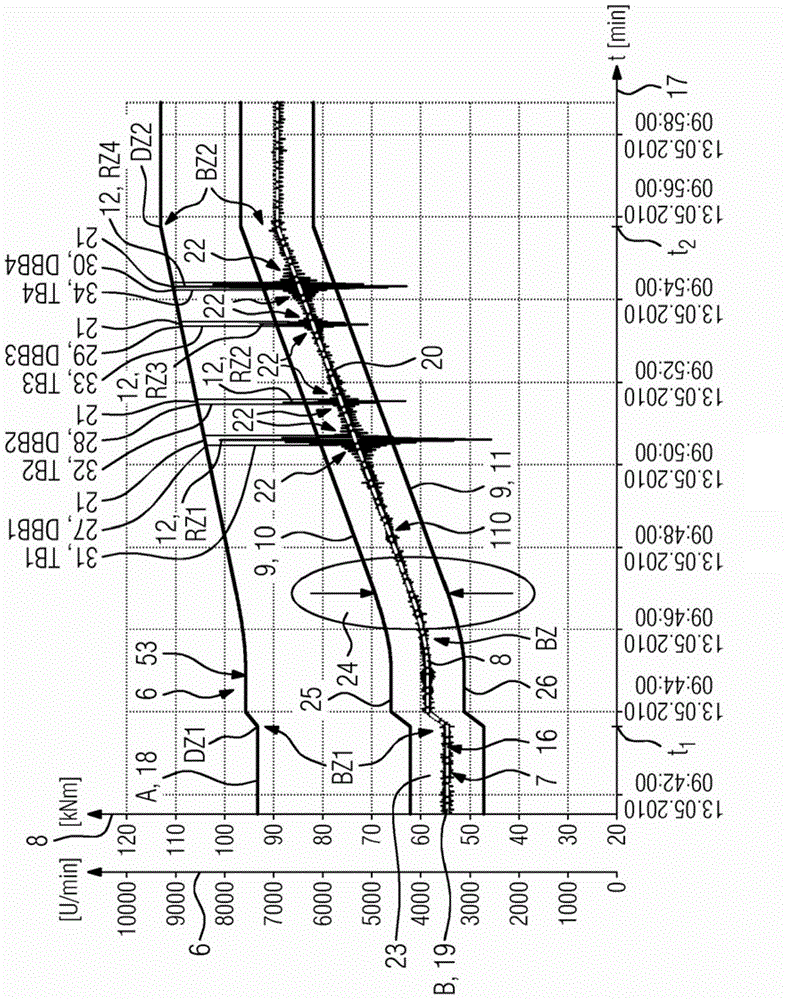

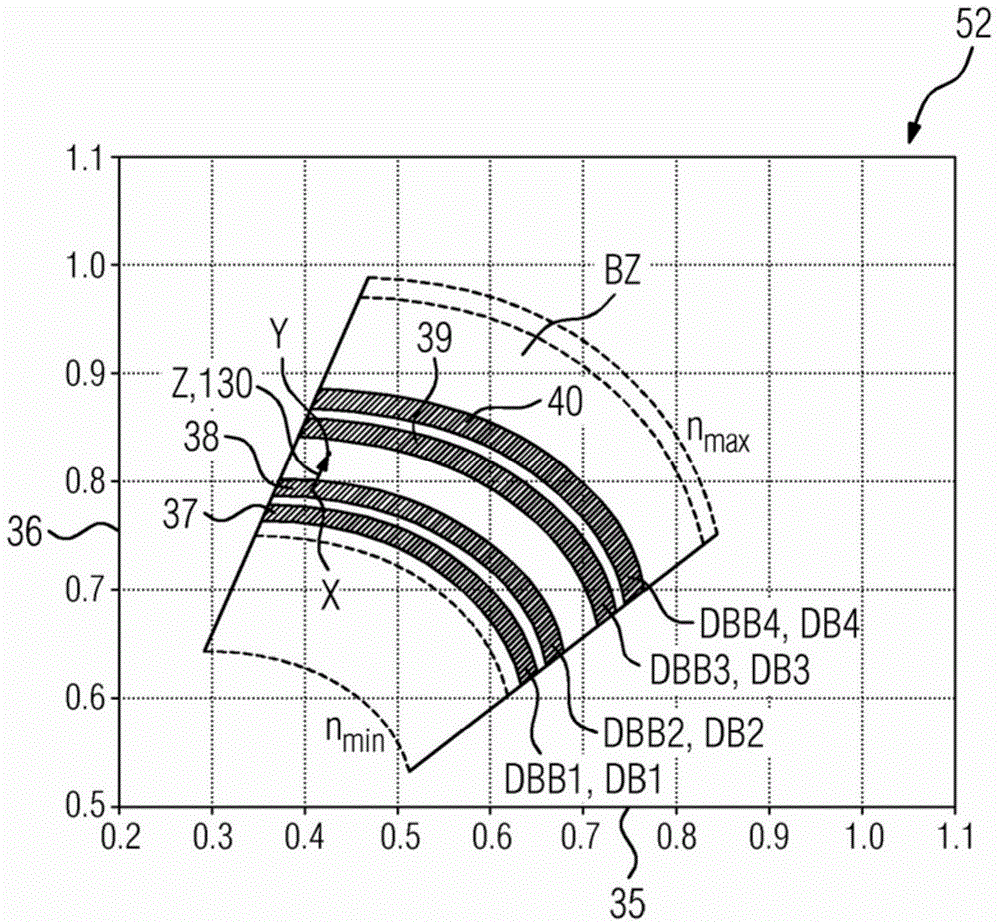

[0080] Example: avoiding continuous operation in torsional resonance excited by a frequency converter of a compressor train ( Figure 1 to Figure 4 )

[0081] figure 1 (Schematically) shows a compressor installation 50 , for example for the liquefaction of natural gas, which has a compressor train 1 with a single-shaft turbo compressor 51 , simply referred to as compressor 51 .

[0082] A converter-controlled electric motor 2 is used in the compressor unit 1 (which drives the compressor unit 1 at a variable rotational speed 6 ) in order to be able to realize the operating speed range of the compressor installation 50 or compressor 51 (power range of the installation 50, see image 3 Compressor characteristic curve family 52).

[0083] In this case, the required performance (for example for the compressor 51 or the compressor assembly 1) in the compressor assembly 1 is changed or increased (cf. figure 2 , required for the power ramp 53) the rotational speed change 130 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com